All About R-404A Refrigerant: Uses, Specs, and Safety Tips

Why R-404A Refrigerant Matters for Commercial Cooling

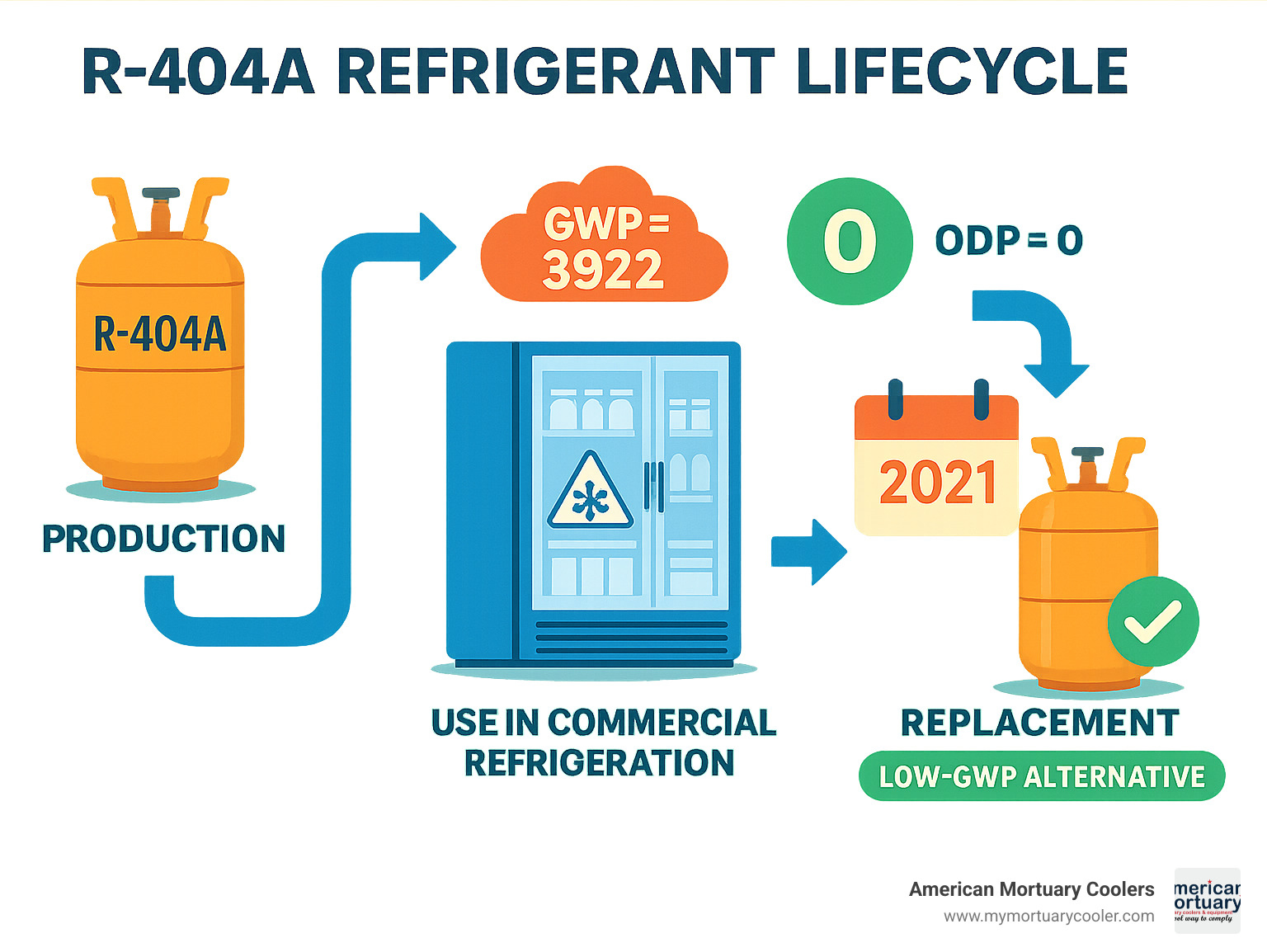

R-404A refrigerant is a widely-used hydrofluorocarbon (HFC) blend that has powered commercial and industrial refrigeration systems for over two decades. This near-azeotropic mixture delivers reliable low-temperature performance in applications ranging from supermarket freezers to mortuary coolers.

Quick R-404A Reference:

- Chemical composition: 44% R-125, 52% R-143a, 4% R-134a

- Safety classification: ASHRAE A1 (non-flammable, low toxicity)

- Boiling point: -46.5°C (-51.7°F)

- Global warming potential: 3,922 (very high)

- Ozone depletion potential: 0 (zero)

- Required lubricant: Polyolester (POE) oil only

- Current status: Being phased down globally due to high GWP

R-404A became the standard choice for commercial refrigeration after replacing ozone-depleting R-502 in the 1990s. However, its extremely high global warming potential means 1 kg of R-404A released equals nearly 4 metric tons of CO₂ in climate impact. This has led to strict regulations worldwide, including EU bans on virgin R-404A since 2021 and U.S. EPA restrictions in retail food refrigeration.

For funeral home directors, understanding R-404A is crucial because many existing mortuary coolers still rely on this refrigerant. While you can continue servicing these systems with recycled R-404A until 2029 in most regions, planning for lower-GWP alternatives is essential.

We're American Mortuary Coolers, a Tennessee-based national supplier of mortuary cooling equipment with extensive experience helping funeral homes steer refrigerant transitions and R-404A system requirements.

Basic r-404a refrigerant glossary:

R-404A Refrigerant: Composition, Lubricants & Core Properties

R-404A refrigerant is a carefully crafted blend - three different ingredients combined in precise amounts to create something better than any single component alone. This hydrofluorocarbon blend has been the go-to choice for commercial freezers and mortuary coolers for over two decades.

The blend combines R-125 at 44% by weight with R-143a at 52% and 4% R-134a. R-125 keeps your system stable and delivers crucial low-temperature performance. R-143a provides most of the cooling power. That small amount of R-134a ties everything together for optimal efficiency.

This blend gives R-404A refrigerant a normal boiling point of -46.5°C (-51.7°F) and earns the ASHRAE A1 safety classification - non-flammable with low toxicity.

Here's how R-404A compares to its predecessor R-502:

| Property | R-404A | R-502 (Replaced) |

|---|---|---|

| Boiling Point | -46.5°C (-51.7°F) | -45.4°C (-49.7°F) |

| Critical Temperature | 72.1°C (161.6°F) | 90.1°C (194.2°F) |

| Safety Classification | A1 | A1 |

| Temperature Glide | 0.7 K | 2.0 K |

| Required Oil | POE | Mineral Oil |

| GWP | 3,922 | 4,657 |

Chemical Make-up & Temperature Glide

R-404A refrigerant behaves almost like a single refrigerant, even though it's three different chemicals mixed together. This happens because it's a near-azeotropic mixture - the components stick together well.

Most refrigerant blends have temperature glide - they don't boil at one specific temperature but across a range. R-404A keeps this glide to just 0.7 K, which is impressively small. This means minimal fractionation during leaks and predictable service characteristics.

Required Lubricants & Material Compatibility

R-404A refrigerant only works with polyolester (POE) lubricants. This is an absolute requirement. POE oils are hygroscopic - they absorb moisture from air like a sponge. When handled properly, POE oils mix perfectly with R-404A and provide superior lubrication compared to older mineral oils.

Retrofitting from R-502 requires getting 95% of old mineral oil out before adding POE. Filter driers must be molecular sieve type - XH9 or XH7 work best. Some elastomers and seals might need replacement, and expansion valves often require recalibration.

For comprehensive pressure-temperature relationships and proper charging procedures: More info about PT charts.

Physical Specs, Environmental Impact & Current Regulations

R-404A refrigerant delivers reliable performance with a normal boiling point of -46.5°C (-51.7°F) and critical temperature of 72.0°C (161.7°F). In medium-temperature systems, R-404A typically achieves a coefficient of performance (COP) of 1.8 with compressor discharge temperatures running about 9°C (14°F) cooler than R-502.

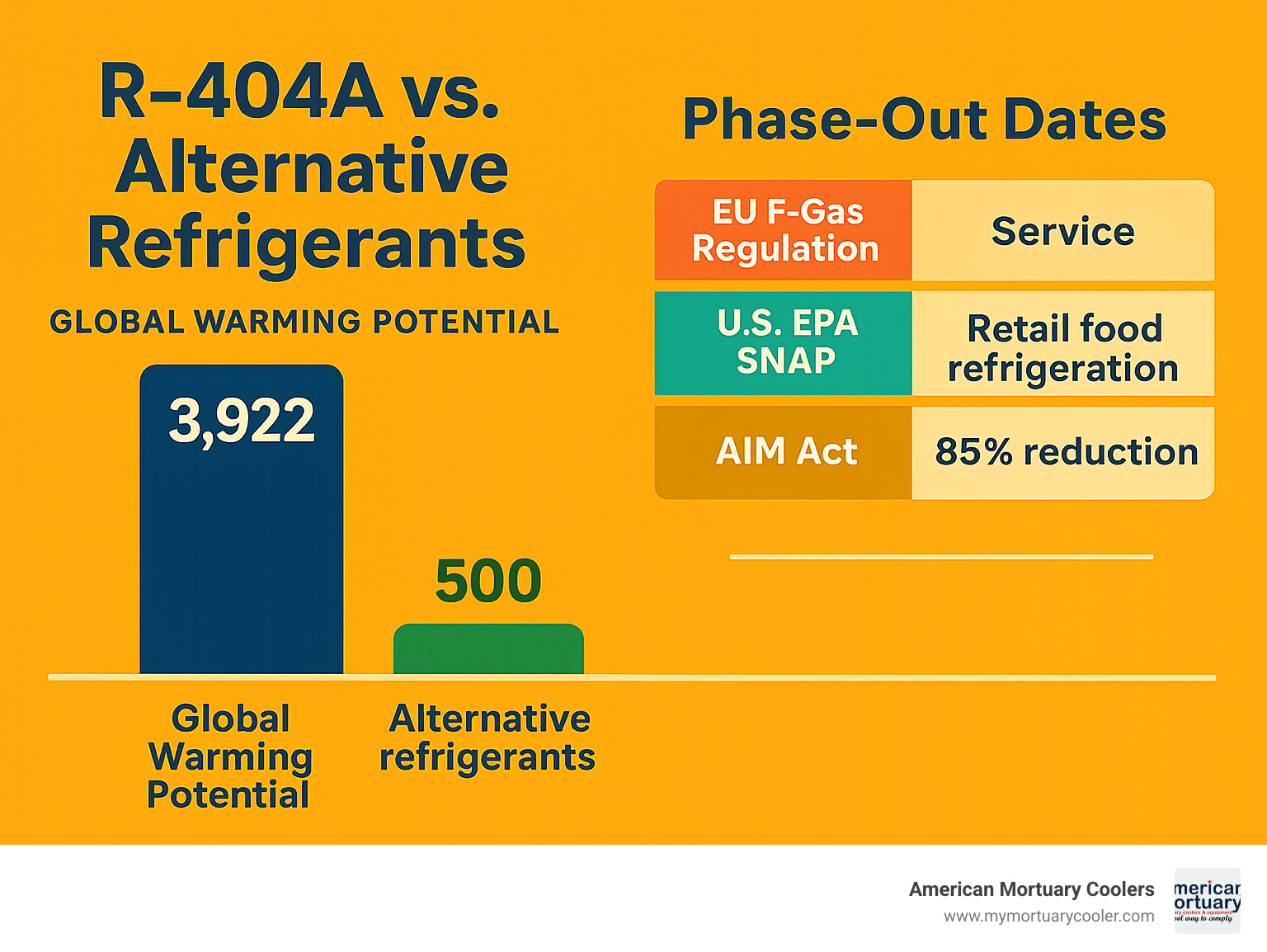

While R-404A refrigerant has zero ozone depletion potential (ODP = 0), its global warming potential tells a different story. With a GWP of 3,922, R-404A ranks among the most climate-damaging refrigerants in use. 1 kg of R-404A escaping has the same climate impact as nearly 4 metric tons of CO₂.

This extreme environmental impact has triggered regulations worldwide. The EU F-Gas Regulation banned virgin R-404A for service starting January 2021. The U.S. EPA SNAP Program has listed R-404A as "unacceptable" in many retail food refrigeration applications. The AIM Act aims for an 85% reduction in HFC production and consumption by 2036.

For detailed federal phase-down requirements: Scientific research on HFC phasedown.

ODP & GWP Explained

Ozone Depletion Potential (ODP) measures how much a substance harms the ozone layer compared to CFC-11. R-404A's ODP of zero means no ozone damage.

Global Warming Potential (GWP) measures greenhouse gas impact over 100 years compared to CO₂. R-404A's GWP of 3,922 means it's nearly 4,000 times more potent than CO₂. A typical mortuary cooler with 5-10 kg of R-404A, if leaked completely, would equal 20-40 metric tons of CO₂ equivalent.

Global & U.S. Phase-Down Timelines

European Union implemented aggressive timelines. The F-Gas quota system started in 2015. January 2021 brought a service ban on virgin R-404A. The EU targets complete HFC phase-out by 2025, with recycled R-404A allowance ending in 2029.

United States regulations follow a different path. EPA SNAP rules listed R-404A as "unacceptable" in various retail categories between 2016-2020. The AIM Act began in 2022 with production caps, targeting 85% reduction by 2036.

For mortuary cooler operators, existing systems can continue with recycled R-404A through 2029 in most regions. New equipment increasingly ships with low-GWP alternatives. Service planning must account for rising R-404A costs and eventual unavailability.

Where R-404A Is Used and the Best Low-GWP Alternatives

R-404A refrigerant became the workhorse of commercial refrigeration in supermarket refrigeration systems, transport refrigeration, industrial cold storage, ice machines, and mortuary cooling applications. Its stability and safety classification made it ideal for funeral homes where reliability matters most.

New mortuary cooler installations increasingly specify low-GWP alternatives as funeral directors plan for the future.

Comparing Performance in Low-Temp vs Medium-Temp Systems

R-404A refrigerant excels in low-temperature applications with evaporating temperatures from -40°F to -10°F, maintaining excellent capacity without performance fade. The refrigerant stays stable with minimal fractionation risk and cooler discharge temperatures that extend compressor life.

In medium-temperature systems running 20°F to 45°F, R-404A performs well with reliable defrost performance. For mortuary applications operating around 35-38°F, R-404A works in that optimal range.

Energy efficiency shows a coefficient of performance (COP) of about 1.8 in medium-temperature cycles, with discharge temperatures averaging 95°C versus 102°C for R-502.

Leading Alternatives & How They Stack Up

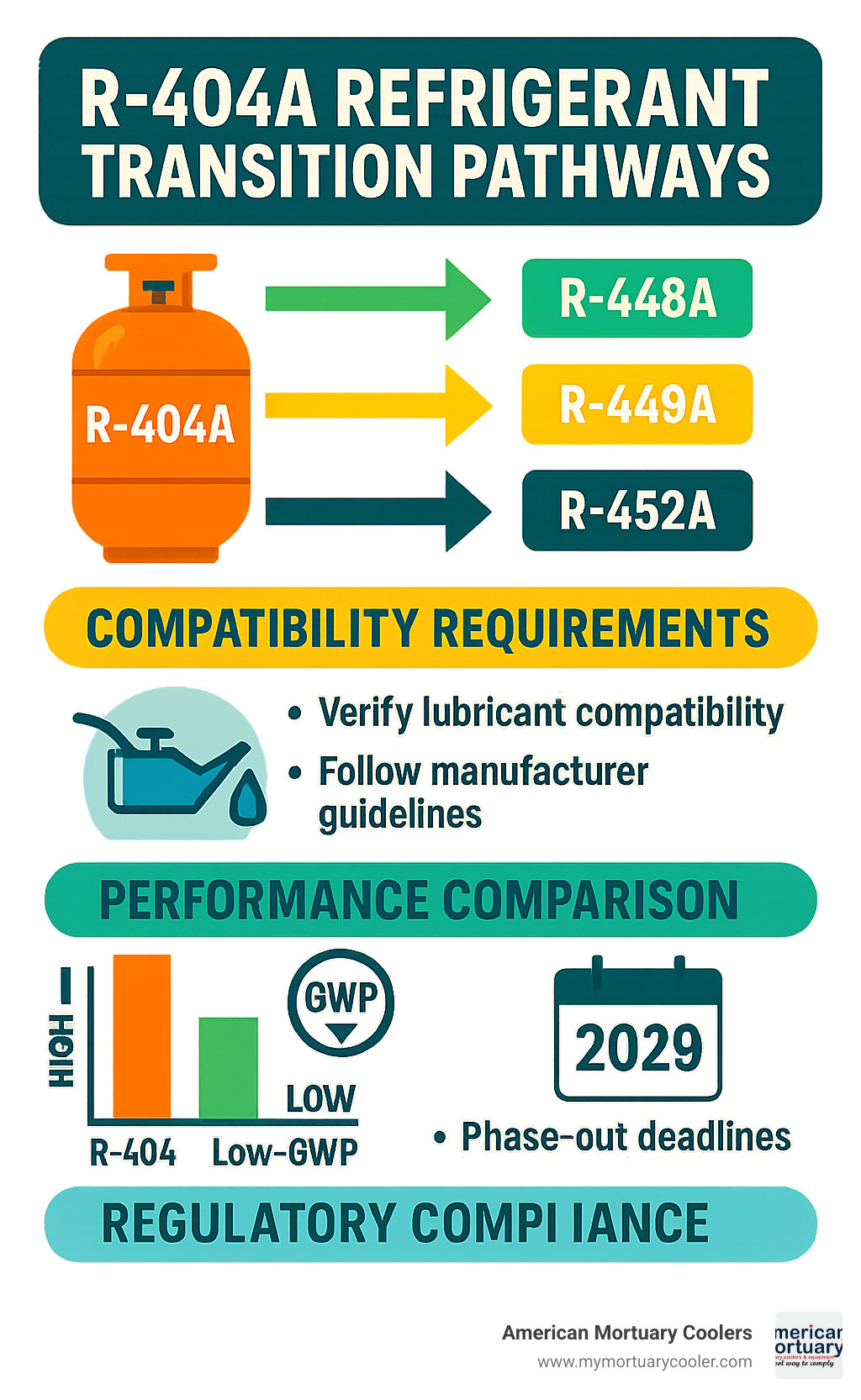

R-448A with GWP of 1,387 works as a drop-in replacement for most R-404A systems. It's compatible with existing POE lubricants and shows up to 11% efficiency improvement. You need about 105% of the original R-404A charge with minimal system changes.

R-449A offers similar benefits with GWP of 1,397 and excellent compatibility. Performance stays comparable with current POE oil. The key requirement is liquid charging to prevent fractionation.

R-452A has GWP of 2,140 - lower than R-404A but higher than other options. It offers good compatibility and wider operating envelope for varying load conditions.

CO₂ (R-744) represents the environmental gold standard with GWP of 1. Transcritical CO₂ systems deliver excellent efficiency but require specialized design and higher initial investment.

R-290 (propane) offers ultra-low GWP of 3 with excellent thermodynamic properties. The A3 flammability classification requires special handling and charge limits.

Retrofitting existing systems usually favors R-448A or R-449A for compatibility. New installations might consider CO₂ or natural refrigerants for long-term environmental benefits.

For detailed low-GWP options: Opteon™ XP40 low-GWP option.

Servicing, Safety & Retrofitting R-404A Systems

Working with R-404A refrigerant demands proper safety procedures despite its non-flammable, low-toxicity classification. The biggest immediate danger is frostbite from liquid contact at -46.5°C (-51.7°F). Asphyxiation presents another risk, especially in basement equipment rooms where R-404A vapor settles.

The Allowable Exposure Limit (AEL) is 1,000 ppm over 8 hours. Essential protective gear includes safety glasses, insulated cryogenic gloves, long sleeves, and closed-toe shoes.

Charging R-404A requires liquid charging to prevent blend fractionation. Use HFC-compatible electronic detectors for leak detection. Recovery must be done as liquid to maintain blend integrity.

Step-by-Step Retrofit From R-404A to R-449A

Converting existing R-404A refrigerant systems to R-449A offers a practical way to reduce environmental impact while maintaining performance.

Start by documenting baseline system performance - record operating pressures, temperatures, superheat, and subcooling values. Photograph the system configuration before starting work.

Recover the existing R-404A completely using proper recovery equipment. Remove refrigerant as liquid when possible and record the recovered amount for calculating new charge quantity.

R-449A retrofits benefit from oil compatibility - existing POE oil typically works fine, though sample and test oil in older systems. Replace contaminated oil and install a new HFC-rated filter drier.

Perform system maintenance during retrofit - repair leaks, replace worn valve cores, and check expansion valve operation. Evacuation must reach 500 microns or better.

Charge with R-449A as liquid using approximately 105% of the original R-404A charge weight. Monitor system response and adjust based on operating parameters.

System startup requires careful monitoring of operating parameters. Adjust the thermostatic expansion valve if needed and verify proper superheat and subcooling values.

Update all system labels to indicate R-449A refrigerant and record final charge weight. Document any component changes for future reference.

Handling & Storage Best Practices for Techs

Always transport cylinders upright and properly secured. Never lift cylinders by the valve or protective cap. Use proper cylinder carts or lifting equipment.

Storage areas need good ventilation and temperature control below 125°F (52°C). Separate full and empty cylinders clearly and label everything.

Recovery cylinder management requires cylinders rated for at least 300 psig service pressure. Never mix different refrigerants and maintain proper labeling.

Ventilation requirements aim for minimum 1 CFM per square foot in work areas. Install refrigerant monitors where required and know emergency shut-off locations.

For detailed pressure values and charging information: More info about R404A pressure values.

Frequently Asked Questions about R-404A Refrigerant

Why is R-404A being phased down despite zero ODP?

While R-404A refrigerant doesn't harm the ozone layer (ODP = 0), which was a huge improvement over R-502, the issue now is climate change. R-404A has a global warming potential of 3,922, meaning it's nearly 4,000 times more powerful than CO₂ as a greenhouse gas.

International climate agreements like the Kigali Amendment shifted focus from ozone protection to greenhouse gas reduction. The U.S. AIM Act and EU F-Gas regulations specifically target high-GWP refrigerants. We solved the ozone problem and now we're tackling climate change with the same systematic approach.

Can I top off an R-404A charge after a small leak?

Yes, you can usually top off R-404A refrigerant systems after minor leaks without worrying about blend separation. R-404A's near-azeotropic behavior means small leaks don't significantly change blend composition.

Always fix the leak first before adding refrigerant. Once repaired, add liquid R-404A to restore proper charge. R-404A must be charged as liquid to prevent fractionation - keep cylinders upright or use liquid withdrawal valves.

Monitor system performance after topping off. For larger leaks or multiple leak incidents, we recommend full charge replacement rather than dealing with potential performance problems.

Which lubricant should I use when replacing R-404A with an HFO blend?

Most HFO-based replacements for R-404A refrigerant work with the same POE oil already in your system. Refrigerants like R-448A and R-449A were designed for existing POE lubricant compatibility, making retrofitting simpler.

Always check specific refrigerant manufacturer recommendations for particular viscosity grades or brands. Consider existing oil condition - older systems may need oil replacement due to degradation or contamination.

Change your filter drier whenever changing refrigerants - this is non-negotiable for removing moisture and contaminants that could interfere with new refrigerant performance.

Conclusion

R-404A refrigerant has been the workhorse of commercial refrigeration for more than twenty years, reliably keeping everything from grocery store freezers to mortuary coolers at the right temperature. But its global warming potential of 3,922 means every pound that leaks has the same climate impact as nearly two tons of CO₂. That's why regulators worldwide are phasing it out.

For funeral home directors, your existing mortuary coolers running on R-404A refrigerant can continue operating with recycled refrigerant through 2029 in most areas. But smart facility managers are planning ahead to avoid being caught off-guard.

Today's low-GWP alternatives like R-448A and R-449A perform just as well as R-404A in most applications. Some even offer better energy efficiency and lower operating costs. The transition doesn't have to be painful with proper planning.

At American Mortuary Coolers, we've been helping funeral homes across the country steer these refrigerant changes for years. Our custom mortuary coolers are designed to work with both current R-404A systems and future low-GWP refrigerants, giving you flexibility as regulations evolve.

Whether you're in Tennessee where we're based, or anywhere else across the contiguous 48 states where we deliver, understanding your options before you're forced to make quick decisions is essential for keeping your facility compliant and operational.

The phase-out of high-GWP refrigerants represents both challenge and opportunity. It requires planning and potentially some investment, but opens the door to more efficient, environmentally responsible cooling technologies that will serve your facility well for decades.

Ready to discuss your refrigerant transition strategy or explore new equipment options? Our team understands both the technical requirements and practical realities of funeral home operations. We're here to help you make informed decisions about refrigerant choices and cooling equipment.

For additional guidance on maintaining precise temperature control during transitions: How to Control Temperature in 5 Simple Steps.