All About 8x15 Walk-In Coolers: Compare Top Options

Why 8x15 Walk-In Coolers Are Perfect for Mid-Size Operations

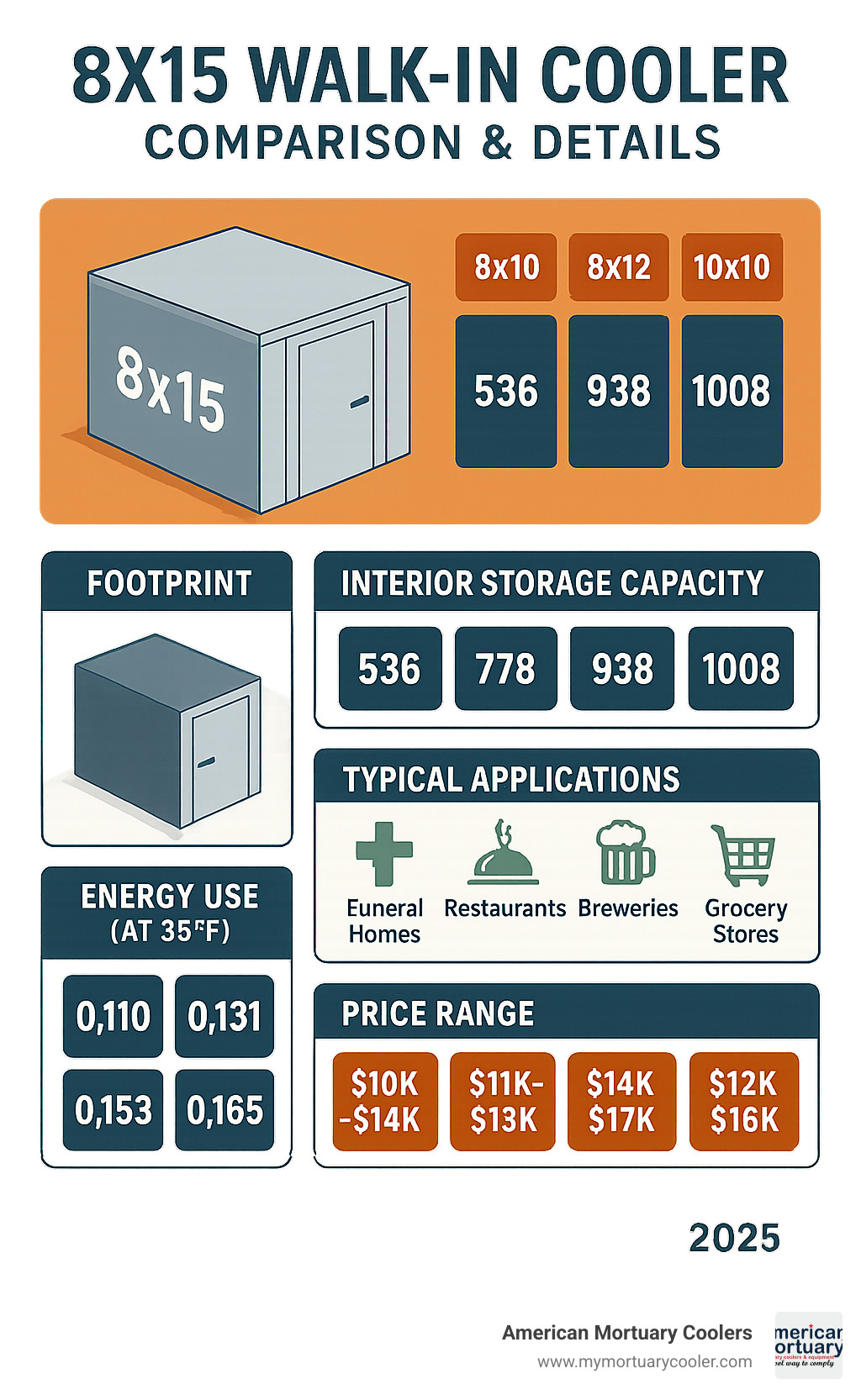

An 8x15 walk in cooler provides 122 square feet of reliable cold storage space, making it ideal for funeral homes, restaurants, breweries, and grocery operations that need more capacity than smaller units but don't require warehouse-scale refrigeration.

Key 8x15 Walk-In Cooler Specifications:

- Interior Space: 122 square feet (8'3" × 14'10" × 8'H)

- Average Price: $14,506 (base unit with refrigeration)

- Energy Use: 0.1529 kWh/day with ¾ HP system

- Insulation: 4" urethane panels with R-25 rating

- Certifications: NSF/ANSI 7 approved for food safety

- Power: Single-phase 208/230V standard

- Shipping: 48-hour quick-ship available

This size strikes the perfect balance between storage capacity and operational efficiency. The modular cam-lock panel design allows for flexible installation, while the ¾ HP refrigeration system maintains consistent +35°F temperatures for medium-temp storage needs.

Whether you're storing floral arrangements, food inventory, or requiring mortuary storage solutions, the 8x15 footprint offers enough space for pallet access through optional 49" wide doors while fitting into most facility layouts without major renovations.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right 8x15 walk in cooler configurations for their specific needs. My background includes working with hundreds of facilities to optimize cold storage solutions that balance capacity, energy efficiency, and budget constraints.

Easy 8x15 walk in cooler word list:

What Is an 8x15 Walk-In Cooler?

Think of an 8x15 walk in cooler as your reliable cold storage workhorse. This medium-temperature refrigerated room gives you a generous 122 square feet of space - that's 8 feet wide by 15 feet long with plenty of room to walk around and organize your inventory without feeling cramped.

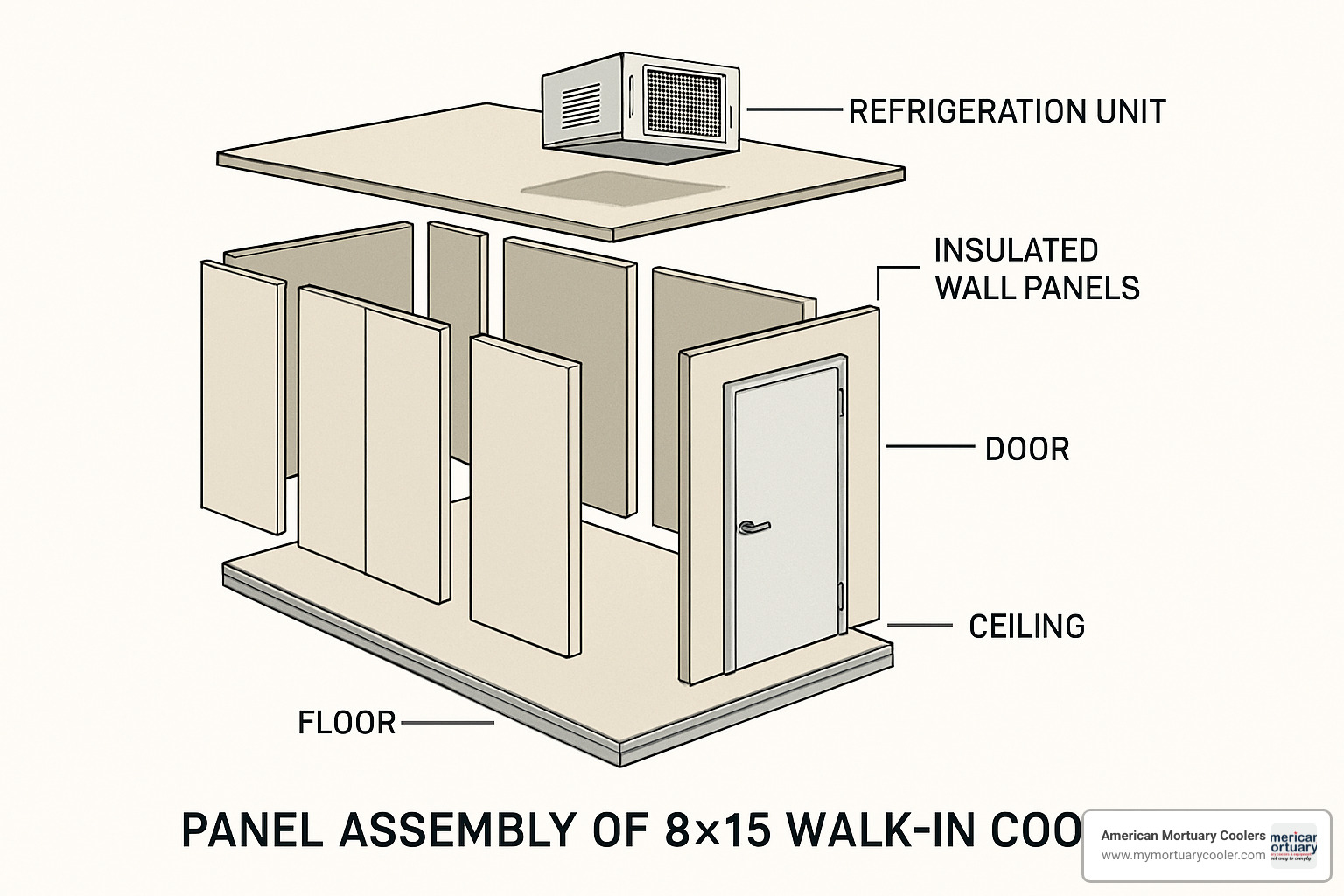

What makes these coolers special is their smart construction. Each unit uses 4-inch thick urethane panels that deliver an impressive R-25 insulation rating. That's fancy talk for "really good at keeping the cold in and the heat out," which translates to lower energy bills and more consistent temperatures.

The panels connect using a clever cam-lock design that's almost like adult Legos - they fit together securely without needing special tools or a PhD in engineering. The panels sandwich that urethane insulation between tough galvanized steel or Galvalume skins that can handle whatever your busy operation throws at them.

Here's something important: these coolers come with NSF/ANSI 7 certification. That's the gold standard for food safety, meaning they're perfectly suited for restaurants, grocery stores, and yes - even mortuary applications where temperature control is absolutely critical.

Standard Features of an 8x15 walk in cooler

Every quality 8x15 walk in cooler comes loaded with features that make your life easier. That 4-inch panel thickness provides significantly better insulation than thinner alternatives, which means your compressor doesn't have to work as hard to maintain temperature.

The galvanized or Galvalume skin on the outside panels is your first line of defense against rust and corrosion. Inside, you'll find vapor-proof LED lighting that's both bright and energy-efficient. The lights come with an exterior switch and pilot light, so you can see if someone left the lights on without opening the door.

Temperature monitoring is handled by a reliable dial thermometer that lets you check conditions at a glance. Safety is serious business, which is why every cooler includes an interior safety release mechanism. This prevents the nightmare scenario of someone getting accidentally locked inside.

Common Applications for an 8x15 walk in cooler

Catering operations love this size because it perfectly handles events for 200-500 people. You can store prepared foods, fresh ingredients, and beverages with room to spare. The optional pallet door makes loading and unloading supplies much easier.

Farm-to-table restaurants rely on these coolers to maintain the cold chain for locally sourced ingredients. The spacious interior accommodates standard food service racks and gives chefs the storage flexibility they need for seasonal menus.

Micro-distilleries and craft breweries use these units for temperature-controlled fermentation, ingredient storage, and holding finished products. Consistent temperature control is crucial for maintaining those carefully crafted flavor profiles.

For mortuary applications, funeral homes find these coolers invaluable during busy periods or when additional capacity is needed. The roomy interior can accommodate multiple gurneys while maintaining the precise temperatures required for proper preservation.

K-12 school cafeterias often choose this size for their meal programs. The NSF certification ensures compliance with strict food safety regulations, while the capacity handles everything from fresh produce to prepared meals for hundreds of students daily.

Key Specifications & Components

When you're investing in an 8x15 walk in cooler, understanding the technical specifications helps you make the right choice for your facility. The foundation of these units starts with their impressive R-25 insulation value from 4-inch urethane panels - that's significantly better than what you'll find in most building walls.

The insulation system creates a thermal barrier that keeps your cooler running efficiently year-round. These panels use foamed-in-place urethane sandwiched between galvanized or Galvalume skins, providing decades of reliable service without the rust issues you might see with cheaper alternatives.

Inside your cooler, you'll find vapor-proof LED lighting that won't corrode in the humid environment. The dial thermometer lets you check temperatures at a glance without opening the door. Most importantly, every unit includes an interior safety release mechanism, so nobody gets accidentally locked inside.

Door sizes typically range from 34 to 49 inches wide, with the larger pallet doors being perfect if you're moving inventory with forklifts or pallet jacks. The self-closing hinges are a godsend during busy periods when staff might forget to fully close the door.

The heart of the system is usually a ¾ HP condensing unit that delivers about 7,020 BTU of cooling capacity - just right for the 122-square-foot space. These units run on standard single-phase 208/230V power, so you won't need expensive electrical upgrades in most facilities.

All quality systems meet DOE compliance standards for energy efficiency and carry UL certification for electrical safety. The panels also meet ASTM E84 flame spread requirements, giving you peace of mind about fire safety in your facility.

Doors and Access Options

Choosing the right door setup for your 8x15 walk in cooler makes a huge difference in daily operations. Standard swing doors at 34 or 36 inches wide work great for most applications. They come with heavy-duty triple hinges, magnetic seals, and keyed locks with that all-important interior safety release.

If you're handling pallets or large inventory, the 49-inch pallet door upgrade is worth every penny. Yes, it costs about $500 more, but the time and labor savings add up quickly when you can roll pallets straight through without wrestling with tight doorways.

Glass display doors are fantastic for retail situations where customers want to see what's available. Sliding doors solve space problems when you don't have room for a door to swing open.

The floor versus floorless decision affects both your upfront costs and long-term convenience. Floorless units save money initially but require a properly sloped concrete pad with drainage. Units with floors cost more but give you complete insulation and much easier cleaning.

Refrigeration System Choices for an 8x15 walk in cooler

Top-mount refrigeration packages are the most popular choice for 8x15 walk in coolers because they're economical and straightforward. The condensing unit sits right on the cooler roof, keeping installation simple and costs reasonable.

Remote refrigeration systems place the noisy condensing unit outside your building, which is great when the cooler is near customer areas or in noise-sensitive locations. The downside is more complex installation with refrigerant lines running between the indoor and outdoor components.

Self-contained units put everything in one compact package, making installation a breeze. They typically cost less upfront, though service might be trickier down the road due to the tight component spacing.

Modern smart controllers are becoming increasingly popular, offering remote monitoring and alarm notifications. While they add to the initial cost, they often pay for themselves through reduced service calls and energy savings.

Pricing, Energy Efficiency & ROI

When you're considering an 8x15 walk in cooler, the investment makes sense both upfront and over the long haul. The average base price sits at $14,506, which covers your complete panel system, standard door, and that reliable ¾ HP refrigeration package that keeps everything running smoothly.

Now, that's just your starting point. You'll want to budget for freight delivery and professional installation labor - trust me, having pros handle the setup saves headaches down the road. If you're thinking about upgrades like floor improvements or that handy pallet door, expect to add anywhere from $500 to $2,000 depending on what bells and whistles you choose.

Here's where things get really interesting from a budget perspective. Your 8x15 walk in cooler sips electricity like a hummingbird - just 0.1529 kWh per day. At typical commercial rates of about 12 cents per kilowatt-hour, you're looking at less than 2 cents daily to run the refrigeration. That works out to under $10 annually just for electricity costs. Pretty remarkable when you think about it.

Don't forget about the money that comes back to you. Tax credits and utility rebates often help offset your initial investment, especially with energy-efficient models. Many power companies offer solid rebates for ENERGY STAR qualified commercial refrigeration equipment, while federal tax credits apply to qualifying installations that meet efficiency standards.

The real beauty shows up in the lifecycle cost analysis. A quality 8x15 walk in cooler typically delivers 15 to 20 years of dependable service with proper care and maintenance. The payback period for upgrading from less efficient cooling methods usually ranges from 2 to 5 years, depending on how much you use it and what your local energy costs look like.

Latest research on energy-efficient compressors shows that newer EC motor technology can slash energy consumption by 20 to 30 percent compared to standard motors. The initial cost premium might take 3 to 5 years to recover through energy savings, but the long-term benefits make it worth considering if you're planning to keep the unit for many years.

The bottom line? An 8x15 walk in cooler isn't just an expense - it's an investment that pays dividends through lower operating costs, improved efficiency, and years of reliable service.

Installation, Customization & Maintenance

Getting your 8x15 walk in cooler installed properly sets the foundation for years of reliable service. The process starts with site preparation, which honestly makes or breaks the entire project.

Your concrete pad needs to be level within ¼ inch across the entire footprint - and trust me, this matters more than you might think. A wobbly cooler leads to door problems, seal issues, and headaches down the road. The pad should be properly sloped for drainage and cured for at least 28 days before installation.

Electrical requirements are straightforward but non-negotiable. You'll need a dedicated circuit sized for the refrigeration system, typically 20-30 amps at 208/230V single-phase. A licensed electrician must handle the hardwired connection, complete with appropriate disconnect switches and overload protection.

Ventilation clearances around the condensing unit ensure your system breathes properly. Top-mount units need at least 24 inches of clearance above and 12 inches on all sides. Cramped equipment runs hot, works harder, and dies younger.

The beauty of the modular cam-lock assembly system is that experienced technicians can complete installation in 4-8 hours. The panels connect with precision-machined cam locks that create airtight seals without requiring specialized tools.

Many manufacturers offer 48-hour quick-ship programs for standard configurations. Custom finishes, diamond-tread kick plates, and specialized ramps are available for unique applications, though they extend lead times.

Warranty coverage typically includes 10-20 years on panels and 5 years on compressors, with 1 year on parts and labor. Extended warranty options are available for critical applications where downtime costs exceed the warranty premium.

More info about walk-in cooler quotes provides detailed guidance on comparing proposals and understanding what's included in different pricing structures.

Installation Requirements for an 8x15 walk in cooler

Forklift or crane access is essential during installation. The largest panels weigh 150-200 pounds, and trying to muscle them into position is a recipe for injury and damaged equipment.

Ceiling height must be at least 9 feet to accommodate the 8-foot panel height plus top-mount refrigeration equipment. Indoor installations need additional height for service access above the condensing unit.

Drainage provisions prevent water accumulation from defrost cycles and cleaning operations. Position floor drains outside the cooler footprint to avoid compromising insulation integrity.

Hardwired electrical connections ensure reliable power supply and code compliance. Temporary power cords might seem convenient, but they're not acceptable for permanent installations and will void equipment warranties.

Maintenance Best Practices

Monthly coil cleaning prevents the dust and debris buildup that slowly strangles your system's efficiency. High-pressure water washing or compressed air cleaning removes accumulated contaminants from condenser coils.

Quarterly door adjustments keep everything sealing properly and operating smoothly. Door hinges, latches, and gaskets need periodic attention to maintain airtight seals and prevent energy loss.

Annual refrigerant checks by qualified technicians catch potential problems before they become expensive disasters. Document refrigerant levels, pressures, and temperatures for trend analysis.

Data logging systems track temperature patterns and identify issues before they cause product loss. Digital monitoring systems can send alerts for temperature excursions or equipment malfunctions.

Regular interior cleaning prevents odor buildup and maintains sanitary conditions. Use food-grade cleaners and sanitizers appropriate for your stored products, following manufacturer recommendations.

Comparing Sizes & Refrigeration Options

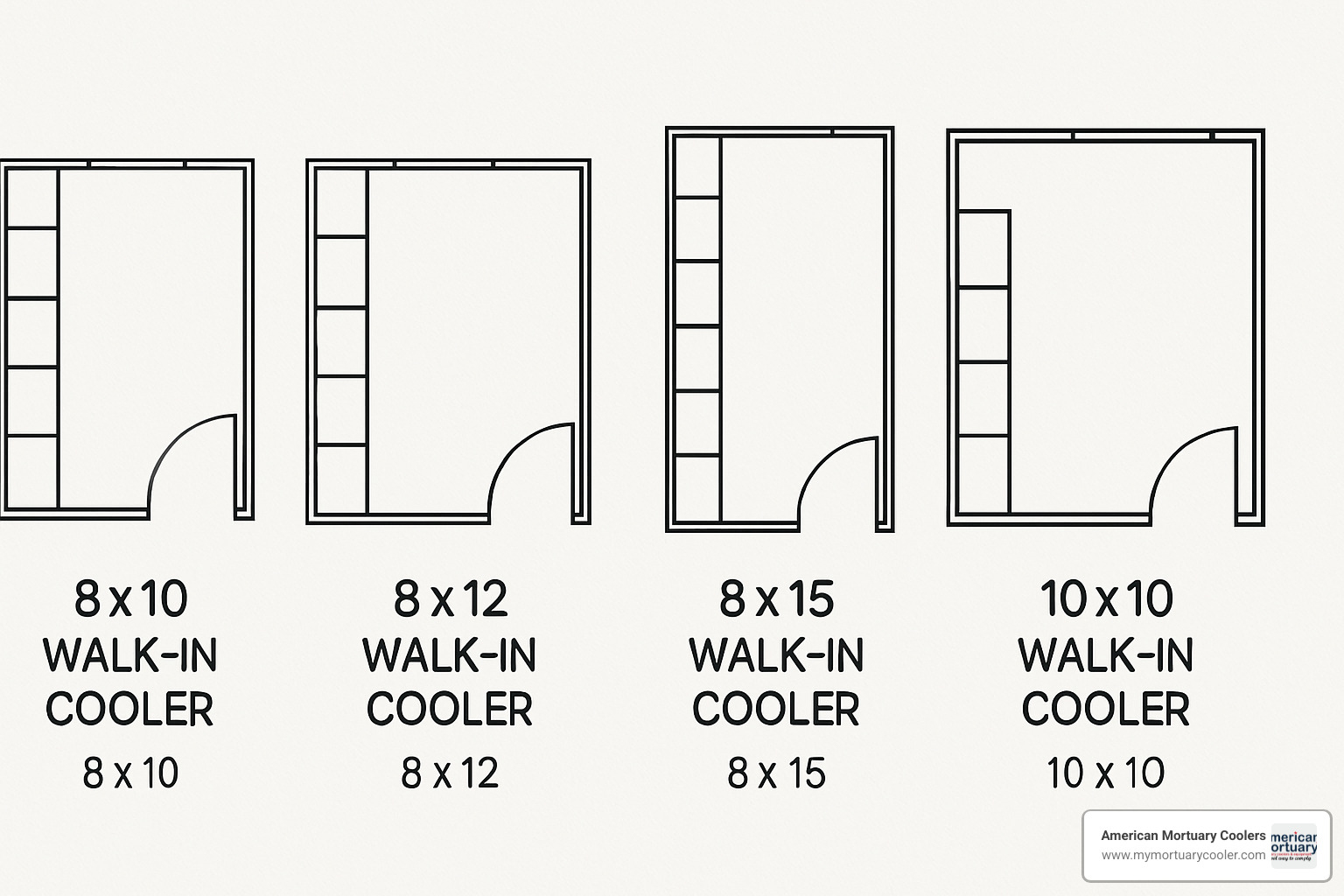

Choosing the right cooler size can feel overwhelming, but let's break down how an 8x15 walk in cooler stacks up against other popular dimensions. With its 122 square feet of floor space, you're looking at roughly 976 cubic feet of storage volume with the standard 8-foot height.

Think of it this way: an 8x10 cooler gives you 81 square feet (648 cubic feet) - perfect for smaller funeral homes but you'll quickly feel cramped if you need pallet access or handle multiple cases simultaneously. The 8x12 size offers a middle ground at 95 square feet (760 cubic feet), giving you more breathing room than the 8x10 while still fitting into tighter spaces than the 8x15.

The 10x10 configuration provides 100 square feet (800 cubic feet) in a neat square footprint. Some facilities love this layout because it fits perfectly into square rooms, but the 8x15 rectangular shape often works better in narrow spaces where every foot of wall space counts.

Storage efficiency really depends on what you're storing and how you organize it. The beauty of the 8x15 walk in cooler is its flexibility - you can configure it for either approach.

Here's where the numbers get interesting with BTU requirements. The ¾ HP system that comes standard on 8x15 walk in coolers hits that sweet spot - powerful enough to handle the load without wasting energy on oversized equipment.

| Size | Interior Sq Ft | Average Price | HP Required |

|---|---|---|---|

| 8x10 | 81 | $12,500 | 0.5 |

| 8x12 | 95 | $13,200 | 0.5 |

| 8x15 | 122 | $14,506 | 0.75 |

| 10x10 | 100 | $13,800 | 0.75 |

When planning your layout, remember to account for door swing clearance and service access around the unit. That 8x15 footprint works beautifully in rectangular prep rooms, but if you're working with a square space, the 10x10 might be your better bet.

More info about 8x10 mortuary coolers can help if you're still weighing your options between sizes.

Why Upgrade to an 8x15 walk in cooler?

Planning for future growth is probably the smartest reason to choose an 8x15 walk in cooler over smaller options. That extra 27-41 square feet compared to 8x10 or 8x12 units might not seem huge today, but when your business grows, you'll be grateful for the breathing room instead of facing a complete cooler replacement.

Pallet access is a game-changer for many operations. With the 49-inch door option, you can roll standard pallets right in and out, which saves your staff's backs and cuts down on handling time.

Those reduced restocking trips add up to real labor savings over time. More storage means fewer deliveries cluttering up your schedule and fewer door openings that let cold air escape.

Here's something interesting about the economics: cost per square foot often favors larger units because you're spreading fixed costs like refrigeration systems, doors, and installation labor over more storage space.

Downsizing from an 8x15 walk in cooler

Sometimes space constraints force your hand, even when you'd prefer the larger unit. Ceiling height limitations, structural restrictions, or local zoning requirements might make the 8x15 impossible to install.

Initial capital limitations are real for many funeral homes, especially newer operations or those dealing with tight cash flow. That $2,000+ price difference between an 8x10 and 8x15 unit might simply exceed what's available in the budget right now.

Alternative cold storage solutions might actually serve you better depending on your specific needs. Multiple reach-in refrigerators scattered throughout your facility, or several smaller walk-ins in different locations, could work better than one centralized larger unit.

The key is being honest about your current needs versus your growth projections, and balancing that against your available space and budget constraints.

Frequently Asked Questions about 8x15 Walk-In Coolers

How long does an 8x15 walk in cooler take to ship?

Good news - most 8x15 walk in cooler units ship surprisingly fast! Standard configurations with basic panel finishes, regular door sizes, and typical refrigeration packages can leave the warehouse in just 48 hours thanks to quick-ship programs.

If you need something custom, plan for about 2-4 weeks for manufacturing. Special finishes, unusual door placements, or upgraded refrigeration systems take extra time since they're built to order. Component availability can sometimes stretch these timelines, especially during busy seasons.

Once your cooler ships, freight delivery typically adds 3-7 days depending on how far you are from the factory. Remote locations or spots that need special delivery equipment might take a bit longer - but we've delivered to some pretty out-of-the-way places over the years!

Here's a pro tip: start scheduling your installation before the cooler arrives. Most installations take 1-2 days including site prep, assembly, and getting everything up and running properly.

Can I install an 8x15 walk in cooler outdoors?

Absolutely! Your 8x15 walk in cooler can handle outdoor installation with the right preparation. The panels are built tough enough for outdoor use, but you'll need proper weatherproofing and a good roof system to keep everything sealed up tight.

The tricky part is dealing with Mother Nature's challenges. Wind loads, snow loads, and earthquake requirements might mean you need engineered foundations and special anchoring systems. Local building codes usually have their own ideas about what's needed for outdoor refrigeration equipment too.

Your condensing unit will need protection from weather, curious vandals, and flying debris. Sometimes that means building a protective enclosure or equipment room - it depends on your local climate and security situation.

Don't forget about the electrical work! Outdoor installations need appropriate conduit, disconnect switches, and ground fault protection. This is definitely a job for a licensed electrician who knows their way around outdoor commercial refrigeration.

What certifications should my 8x15 walk in cooler carry?

The certifications your cooler needs depend on how you'll use it, but there are some must-haves for most applications.

NSF/ANSI 7 certification is essential if you're storing food or anything that needs to meet food safety standards. This covers everything from the materials used to how easy the surfaces are to clean - basically ensuring your cooler won't become a health department nightmare.

UL listing verifies that all the electrical components are safe and won't cause fires or electrocute anyone. Your insurance company and local building inspector will definitely want to see this one.

DOE compliance means your cooler meets federal energy efficiency standards. Beyond being required by law, this certification can open up utility rebates and tax incentives while keeping your electric bills reasonable.

ASTM E84 flame spread ratings ensure the insulation materials won't turn your cooler into a fire hazard. Building codes often specify exactly what ratings they'll accept for interior finishes.

Some states like California, Florida, Oregon, and Washington have their own special requirements for seismic, wind, or hurricane resistance. You might need engineered drawings and official approvals for permits in these areas - but don't worry, experienced suppliers know exactly what's needed for each location.

Conclusion

Finding the perfect 8x15 walk in cooler comes down to understanding your specific needs and making sure everything fits together - literally and figuratively. With 122 square feet of reliable cold storage, you're getting serious capacity without the headaches that come with massive commercial systems.

The numbers tell a compelling story. At just 0.1529 kWh per day, your electricity costs will barely register on the monthly bill. Over the 15-20 year lifespan of a quality unit, that efficiency really adds up. Plus, with utility rebates and tax incentives available for energy-efficient models, the upfront investment often pays for itself faster than you'd expect.

Don't overlook the importance of proper certifications. NSF/ANSI 7, UL, DOE, and ASTM standards aren't just bureaucratic checkboxes - they're your assurance that the equipment will perform safely and reliably for decades. These certifications also keep you eligible for those valuable rebates and tax credits.

Here at American Mortuary Coolers, we've been helping funeral homes and other businesses steer these decisions for years. We understand that choosing an 8x15 walk in cooler isn't just about storage space - it's about finding equipment that works seamlessly with your daily operations.

Our Tennessee headquarters supports customers nationwide across all 48 contiguous states. Whether you're in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, or anywhere in between, we provide the same level of personal service and technical expertise.

We specialize in mortuary applications, but our experience extends to restaurants, breweries, and any operation that needs dependable refrigeration. Every unit we deliver is built to handle your specific requirements, with direct shipping and comprehensive support from day one through years of reliable service.

The funeral industry demands equipment that works without fail, and that's exactly what we deliver. Our custom approach means you get precisely what you need - no compromises, no settling for "close enough."

Ready to move forward with your 8x15 walk in cooler project? Contact us today for a detailed quote custom to your specific needs. We'll walk you through every option and make sure you get exactly what works best for your facility.

For a deeper dive into all your refrigeration options, check out our Comprehensive Guide to Walk-In Cooler Options. It covers everything from basic specifications to advanced features that can make your operation more efficient.