All About 404 Refrigerant: Uses, Properties, and Safety

Why 404 Refrigerant Remains Critical for Commercial Cooling

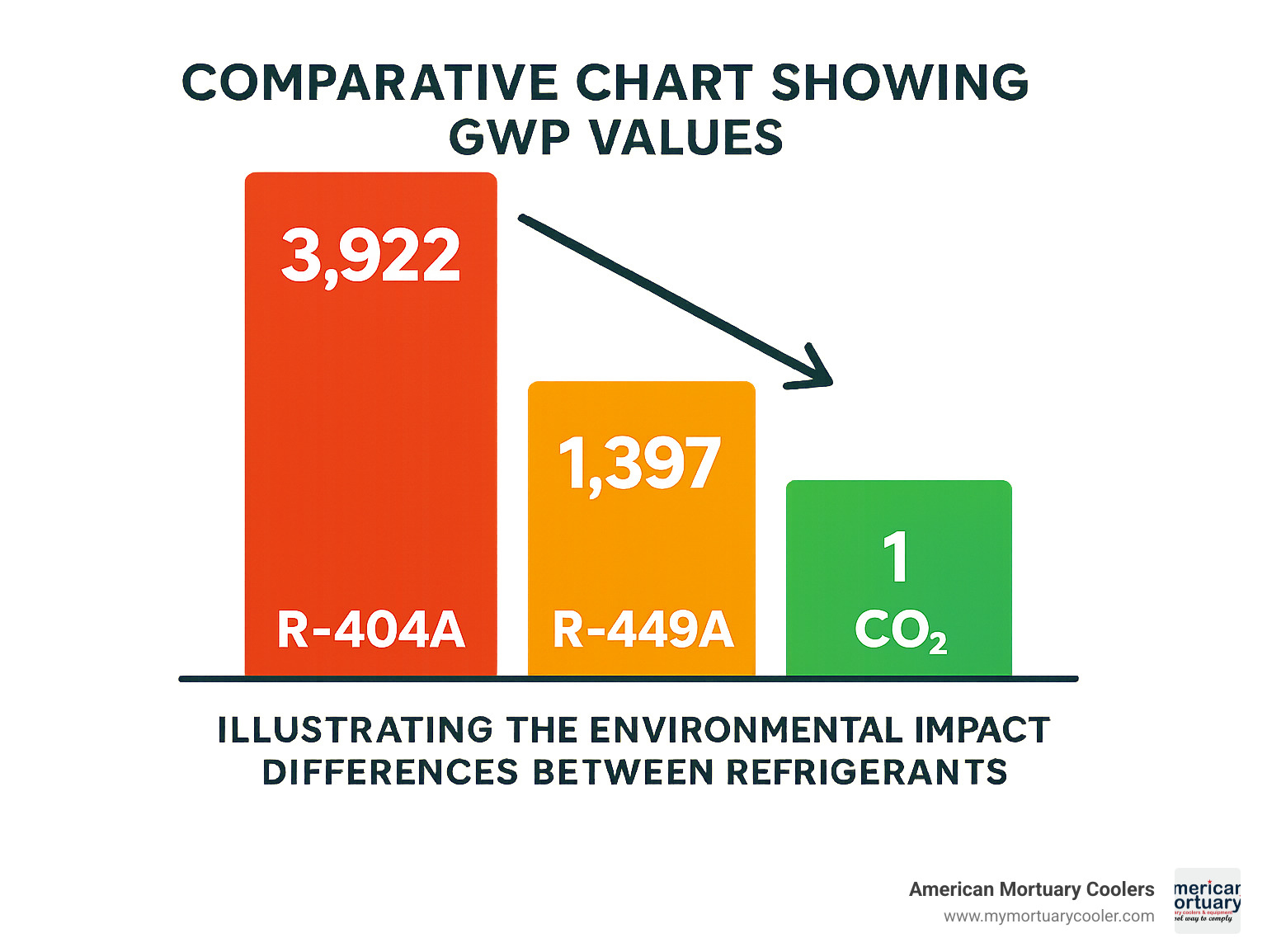

404 refrigerant (R-404A) is a hydrofluorocarbon (HFC) blend widely used in commercial refrigeration systems, particularly for low-temperature applications like mortuary coolers, supermarket freezers, and cold storage facilities. Despite facing regulatory phase-outs due to its high global warming potential of 3,922, R-404A continues to serve as the backbone of countless refrigeration systems worldwide.

Key Facts About 404 Refrigerant:

- Composition: 44% R-125, 52% R-143a, 4% R-134a by weight

- Boiling Point: -46.5°C (-51.6°F) at atmospheric pressure

- Safety Rating: ASHRAE A1 (non-flammable, low toxicity)

- Primary Use: Low and medium-temperature commercial refrigeration

- Environmental Impact: Zero ozone depletion, but GWP of 3,922

- Regulatory Status: Restricted for new equipment in Europe (2020), service bans in effect (2021)

R-404A was developed in the mid-1990s as a direct replacement for ozone-depleting refrigerants like R-502 and R-22. Its near-azeotropic behavior made it an ideal drop-in substitute, offering equivalent cooling capacity while eliminating ozone depletion concerns. However, with 1 kg of released R-404A equivalent to nearly 4 tonnes of CO2 in greenhouse gas impact, environmental regulations now drive the industry toward lower-GWP alternatives.

For mortuary applications, 404 refrigerant provides the reliable, consistent cooling needed to maintain proper body storage temperatures around -4°C (25°F). The blend's stability and non-flammable properties make it particularly suitable for sensitive environments where safety and precision are paramount.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in refrigeration systems using 404 refrigerant for funeral home applications. My background includes helping funeral directors steer the transition from legacy refrigerants while maintaining the reliable cooling performance essential for their operations.

404 refrigerant vocabulary:

What Is 404 Refrigerant (R-404A)?

404 refrigerant is essentially a carefully crafted cocktail of three different cooling chemicals that work together like a well-oiled team. Officially called R-404A, this blend combines 44% HFC-125, 52% HFC-143a, and 4% HFC-134a by weight to create what's known as a ternary blend.

What makes this mixture special is its near-azeotropic behavior - a fancy way of saying it acts almost like a single refrigerant throughout the entire cooling cycle. This characteristic was a game-changer when the industry needed reliable replacements for older refrigerants.

The ASHRAE A1 safety classification gives 404 refrigerant its stamp of approval for use in occupied spaces. This rating means it won't catch fire and has low toxicity - crucial factors when you're dealing with sensitive environments like funeral homes where safety can't be compromised.

Perhaps most importantly for environmental regulations, R-404A has zero ozone depletion potential (ODP = 0.0). While it may have a high global warming potential, at least it doesn't punch holes in our protective ozone layer.

Chemical Composition & Naming Conventions

The "404" name isn't random - it follows a specific numbering system called ASHRAE Standard 34. The first digit (4) tells us it's a mixture of different refrigerants, while the remaining digits (04) identify this particular blend recipe. You might also see it called HP62 in some markets, which is just another name for the same product.

Each component in 404 refrigerant brings something important to the table. HFC-125 makes up nearly half the blend and provides the low-temperature punch needed for commercial freezing applications. HFC-143a, being the largest component at over half the mixture, delivers the thermodynamic efficiency that keeps systems running smoothly. The small amount of HFC-134a acts like a stabilizer, fine-tuning the temperature-pressure relationship for optimal performance.

Why 404 Refrigerant Replaced R-502 & R-22

The story of 404 refrigerant really begins with environmental necessity. The Montreal Protocol essentially gave older refrigerants like R-502 and R-22 their walking papers due to ozone depletion concerns. R-502, a CFC blend that was the workhorse of commercial refrigeration, had an ozone depletion potential of 0.33 - definitely not sustainable.

404 refrigerant was specifically engineered to be R-502's worthy successor. The chemists did their homework, creating a blend that matched R-502's thermodynamic properties across the entire operating range. This meant existing systems could be converted without major overhauls - a huge relief for businesses facing mandatory refrigerant changes.

Here's a bonus: 404 refrigerant actually runs cooler than its predecessor. Compressor discharge temperatures are about 9°C (14°F) lower than with R-502, which can extend equipment life and keep lubricants happier.

Key Properties and Environmental Impact

When you're working with 404 refrigerant, understanding its physical properties helps explain why it became so popular in commercial refrigeration. R-404A has a boiling point of -46.5°C (-51.6°F) at atmospheric pressure, which makes it perfect for those demanding low-temperature jobs like keeping mortuary coolers running smoothly.

The critical temperature sits at 72.1°C (161.7°F) with a critical pressure of 3,732 kPa. What this means in practical terms is that R-404A can handle the temperature swings and pressure demands of commercial systems without breaking a sweat.

For funeral homes, these properties translate to reliable, consistent cooling that maintains proper body storage temperatures around -4°C (25°F). The refrigerant ships as a liquefied gas under its own vapor pressure, which simplifies handling and storage.

But here's where things get complicated. While 404 refrigerant performs beautifully from a technical standpoint, its environmental impact has become a major concern. R-404A carries a Global Warming Potential (GWP) of 3,922 over a 100-year timeframe. To put that in perspective, releasing just 1 kg of this refrigerant has the same long-term warming effect as releasing nearly 4 tonnes of CO2 into the atmosphere.

This high GWP rating has put R-404A squarely in the crosshairs of environmental regulations worldwide. The Kigali Amendment to the Montreal Protocol specifically targets high-GWP refrigerants like this one, creating phase-down schedules that affect everything from new equipment sales to service procedures.

Understanding GWP & ODP Numbers

Think of Global Warming Potential (GWP) as a comparison tool that measures how much heat a greenhouse gas traps compared to CO2 over 100 years. When 404 refrigerant has a GWP of 3,922, it means this refrigerant is nearly 4,000 times more potent than CO2 as a greenhouse gas.

The good news is that R-404A has an Ozone Depletion Potential (ODP) of 0.0, meaning it doesn't harm the ozone layer at all. This zero ODP was actually the main reason the industry adopted it back in the 1990s when we were phasing out ozone-depleting refrigerants like R-502.

But times change, and now the focus has shifted from ozone protection to climate impact. Regulatory agencies use GWP thresholds to determine which refrigerants get restricted first. The EU's F-Gas Regulation specifically targets refrigerants with GWP above 2,500, which puts 404 refrigerant well above that line.

Temperature-Pressure Charts & System Tuning

Getting the best performance from 404 refrigerant systems requires understanding how temperature and pressure work together. At typical mortuary cooler operating conditions of -4°C (25°F), R-404A runs at approximately 24 psig suction pressure.

One critical requirement when working with 404 refrigerant is using POE (polyolester) oil. Unlike older mineral oils, POE oil mixes properly with R-404A and protects compressor components. The recommended superheat range typically falls between 30°F to 45°F for proper compressor protection.

For detailed guidance on reading pressure-temperature relationships and optimizing your system, check out A Practical Guide to Finding a PT Chart for R404A Refrigerant.

Applications and Best Practices for 404 Refrigerant

Walk through any supermarket's frozen food section, and you're likely experiencing 404 refrigerant at work. Those humming display cases keeping your ice cream frozen? There's a good chance they're running on R-404A. This versatile refrigerant has become the workhorse of commercial cooling because it simply gets the job done, day after day.

404 refrigerant shines in applications where consistent low temperatures are non-negotiable. Commercial freezers and display cases in grocery stores rely on its steady performance to keep frozen foods safe. Refrigerated transport trucks use R-404A to maintain cargo temperatures during long hauls across varying climates. Cold storage warehouses depend on it for large-scale frozen food preservation.

Using 404 Refrigerant in Mortuary Coolers

In the funeral industry, there's no room for "close enough" when it comes to cooling. 404 refrigerant has earned its place in mortuary applications because it delivers the rock-solid reliability that funeral directors need. We've installed countless systems using R-404A that maintain steady temperatures around -4°C (25°F) with minimal fluctuation.

Body storage requires more than just cold temperatures - it demands precision. The systems we design using 404 refrigerant typically hold temperatures within ±1°C variation, ensuring proper preservation conditions. This tight control prevents the temperature swings that could compromise the preservation process.

From our experience serving funeral homes across the country - from basement morgues in Chicago to ground-level facilities in Dallas - 404 refrigerant systems adapt well to different environments. The consistent performance we've observed, regardless of installation location or ambient conditions, gives funeral directors the peace of mind they need.

Retrofitting Existing Equipment with 404 Refrigerant

Converting an older system to 404 refrigerant isn't just a simple refrigerant swap - it requires careful attention to several critical details. The most important change involves switching from traditional mineral oil to POE (polyolester) lubricant, since R-404A simply won't work with the old oil.

The retrofit process starts with a complete oil change that removes every trace of the old mineral oil. Next comes filter-drier replacement with units specifically rated for HFC refrigerants like R-404A. Leak testing becomes crucial before introducing the new refrigerant.

The good news is that R-404A's near-azeotropic behavior simplifies the conversion compared to some newer alternatives. However, proper charging requires drawing refrigerant from the cylinder as liquid to prevent fractionation of the blend components.

Lubricants, Components, and Compressor Life

404 refrigerant systems require POE oil, but choosing the right viscosity grade matters for long-term performance. We typically specify ISO 32 or ISO 46 viscosity grades depending on the compressor manufacturer's requirements and the specific operating conditions of the installation.

One pleasant surprise with R-404A is its effect on compressor discharge temperature. Systems running 404 refrigerant typically see discharge temperatures up to 9°C lower than they would with older refrigerants like R-502. This temperature reduction translates to less stress on compressor components and better lubricant stability over time.

Regulations, Phase-Out, and Low-GWP Alternatives

The story of 404 refrigerant has taken an unexpected turn. What started as the environmental hero that saved the ozone layer has now become the villain in the fight against climate change. It's a classic case of solving one problem only to find another.

The European Union fired the first shot in 2020, banning R-404A in new commercial refrigeration equipment. Then came the knockout punch in January 2021 - a complete service ban on virgin 404 refrigerant for systems with GWP above 2,500. The United States followed suit with the EPA AIM Act, though they're taking a more gradual approach.

For funeral homes using 404 refrigerant in their mortuary coolers, this creates real challenges. You can't just ignore regulations and hope they go away - especially when refrigerant prices start climbing due to reduced supply quotas. The Kigali Amendment ensures this isn't just a regional issue but a global shift affecting refrigerant availability worldwide.

Timeline for 404 Refrigerant Restrictions

Understanding when these restrictions hit helps you plan ahead instead of scrambling at the last minute. Europe moved fastest, implementing their service bans while many operators were still figuring out what GWP even meant.

The European timeline reads like a countdown to phase-out. The 2020 ban on new equipment was just the beginning. The 2021 service ban on virgin R-404A created immediate headaches for system operators. Looking ahead, 2025 brings further restrictions on system sizes, and by 2030, the quota system will reduce HFC availability to just 21% of baseline levels.

USA regulations follow a different rhythm. The AIM Act phase-down began in 2022, but stockpiling deadlines and application-specific bans are rolling out gradually through 2026. The ultimate goal remains the same - reducing HFC production and consumption to 15% of baseline by 2036.

Top Alternatives to 404 Refrigerant

Finding the right replacement for 404 refrigerant feels like dating after a long relationship - you know what you liked about the old one, but you need something that works better for the future.

R-448A and R-449A are the most popular choices, with GWP values around 1,387 and 1,397 respectively. Both offer good energy performance and can work in existing systems with some modifications. Opteon XP40 (R-449A) has become our go-to recommendation for mortuary cooler replacements because it delivers similar cooling capacity with about 65% lower GWP.

R-452A offers a GWP of 2,140, which is better than R-404A but still above some regulatory thresholds. R-407F brings the GWP down to 1,824 and works well as an R-22 replacement, though it has moderate temperature glide that requires careful system tuning.

Natural refrigerants represent the ultimate low-GWP solution. CO2 systems have a GWP of just 1, but they require completely different system designs with high-pressure components. Hydrocarbons like R-290 (propane) and R-600a (isobutane) offer very low GWP but bring flammability concerns that require special safety measures.

For mortuary applications, we typically recommend staying with HFC/HFO blends like R-449A that provide the reliability funeral homes need without the complexity of natural refrigerants or flammability concerns of A2L options.

Safety, Handling, and End-of-Life Management

Working with 404 refrigerant safely doesn't require rocket science, but it does demand respect for basic precautions. Despite R-404A's friendly ASHRAE A1 classification as non-flammable and low-toxicity, this refrigerant can still bite you if you're not careful.

The biggest safety concern we see in the field is frostbite from liquid contact. At ‑46.5 °C (-51.6 °F), liquid R-404A will freeze skin tissue almost instantly. Asphyxiation risk becomes serious in enclosed spaces like basement morgues or small mechanical rooms; R-404A vapor is heavier than air and can displace oxygen without warning.

Transportation regulations classify 404 refrigerant under UN 3337 as a liquefied gas. This means proper cylinder handling during delivery to funeral homes across our service area. Cylinders must stay upright, secured, and away from heat sources during transport and storage.

404 Refrigerant Safety Classification & PPE

The ASHRAE A1 rating makes 404 refrigerant one of the safer options available, but "safer" doesn't mean "foolproof." Proper personal protective equipment prevents most accidents before they happen.

- Insulated gloves are non-negotiable when working with liquid R-404A. We recommend PVA, neoprene, or butyl rubber gloves that can handle extreme cold.

- Safety goggles protect against liquid splashing during connection and disconnection procedures.

- Well-ventilated workspaces prevent vapor accumulation that could lead to oxygen displacement.

The exposure limit for R-404A is set at 1,000 ppm for an 8-hour time-weighted average—well above what you'd normally encounter during routine service. However, confined spaces require extra precautions including atmospheric monitoring and sometimes self-contained breathing apparatus.

Recovery, Recycling, and Disposal Procedures

Proper end-of-life management of 404 refrigerant isn't just good environmental stewardship—it’s the law. EPA Section 608 regulations require recovering refrigerants before system disposal or major repairs, and the penalties for non-compliance can be steep.

- Recovery procedures must achieve specific vacuum levels depending on your system type. High-pressure systems need 10 in Hg vacuum (or 0 psig), while low-pressure systems require 25 in Hg vacuum.

- Once recovered, 404 refrigerant has several end-of-life paths:

- Recycling cleans the refrigerant for reuse in the same system—perfect for routine maintenance.

- Reclamation processes it to ARI 700 standards for resale, giving the refrigerant new life in different equipment.

- Proper destruction at approved facilities handles refrigerant that can't be reused.

For comprehensive handling and emergency-response information, reference the R-404A Safety Data Sheet (PDF).

Frequently Asked Questions about 404 Refrigerant

What GWP makes 404 refrigerant a target for phase-out?

The short answer is 3,922 - that's the Global Warming Potential that puts 404 refrigerant squarely in regulators' crosshairs. To put this number in perspective, if you accidentally release just one pound of R-404A, it has the same long-term warming effect as releasing nearly two tons of CO2 into the atmosphere.

This astronomically high GWP comes from the fluorinated compounds that make up the blend. HFC-125 and HFC-143a - the two main components - stick around in the atmosphere for decades once released. Most regulatory frameworks target refrigerants above 2,500 GWP for restrictions, and 404 refrigerant blows past that threshold by over 1,400 points.

Can I top-off a leaking system with a different blend?

This is one of those questions where the answer is a firm no - and I really mean it. Mixing 404 refrigerant with other blends is like trying to fix a recipe by adding random ingredients. You'll end up with something that doesn't work properly and can't be fixed easily.

R-404A is a precisely formulated mixture where each component plays a specific role. When you add a different refrigerant, you're changing the entire chemistry of the system. The temperature-pressure relationships shift, oil compatibility changes, and system performance becomes unpredictable. Worse yet, mixed refrigerants can't be recycled or reclaimed - they become contaminated waste.

If your system is leaking frequently enough that you're considering shortcuts, it's time to address the real problem. Locate and repair the leak first, then recover whatever R-404A remains. After proper evacuation, you can either recharge with fresh 404 refrigerant or - given current prices and availability - consider converting to an approved alternative like R-449A.

Which oil grade should I use after converting to 404 refrigerant?

When you switch to 404 refrigerant, you absolutely must use polyolester (POE) oil - there's no getting around this requirement. R-404A and traditional mineral oil are about as compatible as oil and water, which means your compressor won't survive long with the wrong lubricant.

The specific POE viscosity depends on your compressor manufacturer's specs and operating conditions. ISO 46 is the most common grade we specify for mortuary coolers because it handles the typical operating range well. ISO 32 works for higher-temperature applications, while ISO 68 is better for extremely low-temperature systems.

Always check your compressor manufacturer's recommendations first - they know their equipment best. Some manufacturers have specific oil formulations they prefer, and using the wrong viscosity can void warranties or cause premature compressor failure.

Conclusion

The future of 404 refrigerant tells a story of transition. While R-404A has served the refrigeration industry faithfully for decades, providing reliable cooling for everything from grocery store freezers to funeral home body storage systems, its days as the go-to choice are numbered.

The numbers don't lie - with a GWP of 3,922, 404 refrigerant packs nearly 4,000 times the warming punch of CO2. That's why regulators worldwide are tightening the screws. Europe has already banned virgin R-404A for service work, and similar restrictions are coming to the United States.

But here's the thing - this transition doesn't have to be scary. At American Mortuary Coolers, we've been helping funeral directors across all 48 contiguous states steer these changes for years. Whether you're running a small family funeral home in rural Tennessee or managing multiple locations across the Southwest, we understand that your cooling systems can't fail. Ever.

Regulatory compliance isn't just about avoiding fines - it's about future-proofing your business. The funeral directors who are getting ahead of this transition now are the ones who'll sleep better knowing their systems are built to last. They're choosing efficiency upgrades that not only meet environmental requirements but often save money on energy costs too.

The sustainable choices available today would have seemed impossible just a few years ago. Refrigerants like R-449A offer nearly identical performance to 404 refrigerant while cutting greenhouse gas impact by 65%. That's the kind of improvement that makes everyone feel good about the change.

Our experience designing custom mortuary coolers has taught us that every funeral home has unique needs. The system that works perfectly in a basement morgue in Chicago might need different specifications for a ground-level facility in Phoenix. That's why cookie-cutter solutions don't work - and why our Tennessee-based team takes the time to understand your specific situation.

For those ready to dive deeper into the technical details, The Definitive Guide to R404A Refrigerant provides comprehensive information for system designers and operators who want to understand every aspect of R-404A performance and alternatives.

The refrigeration industry is evolving faster than ever, but that evolution brings opportunity. While existing 404 refrigerant systems will continue serving faithfully for years to come, new installations increasingly feature environmentally preferred alternatives that deliver the same rock-solid performance funeral directors depend on.

Change is never easy, especially when it involves the systems that protect your most important responsibilities. But with the right partner, this transition becomes an opportunity to upgrade, improve efficiency, and build systems that will serve your families for decades to come.