A–Z Guide to Refrigerated Products and Storage

Why Refrigerated Systems Are Essential for Food Safety and Global Commerce

Refrigerated systems form the backbone of modern food distribution, keeping perishable goods safe from farm to table. Here's what you need to know about refrigerated storage and transport:

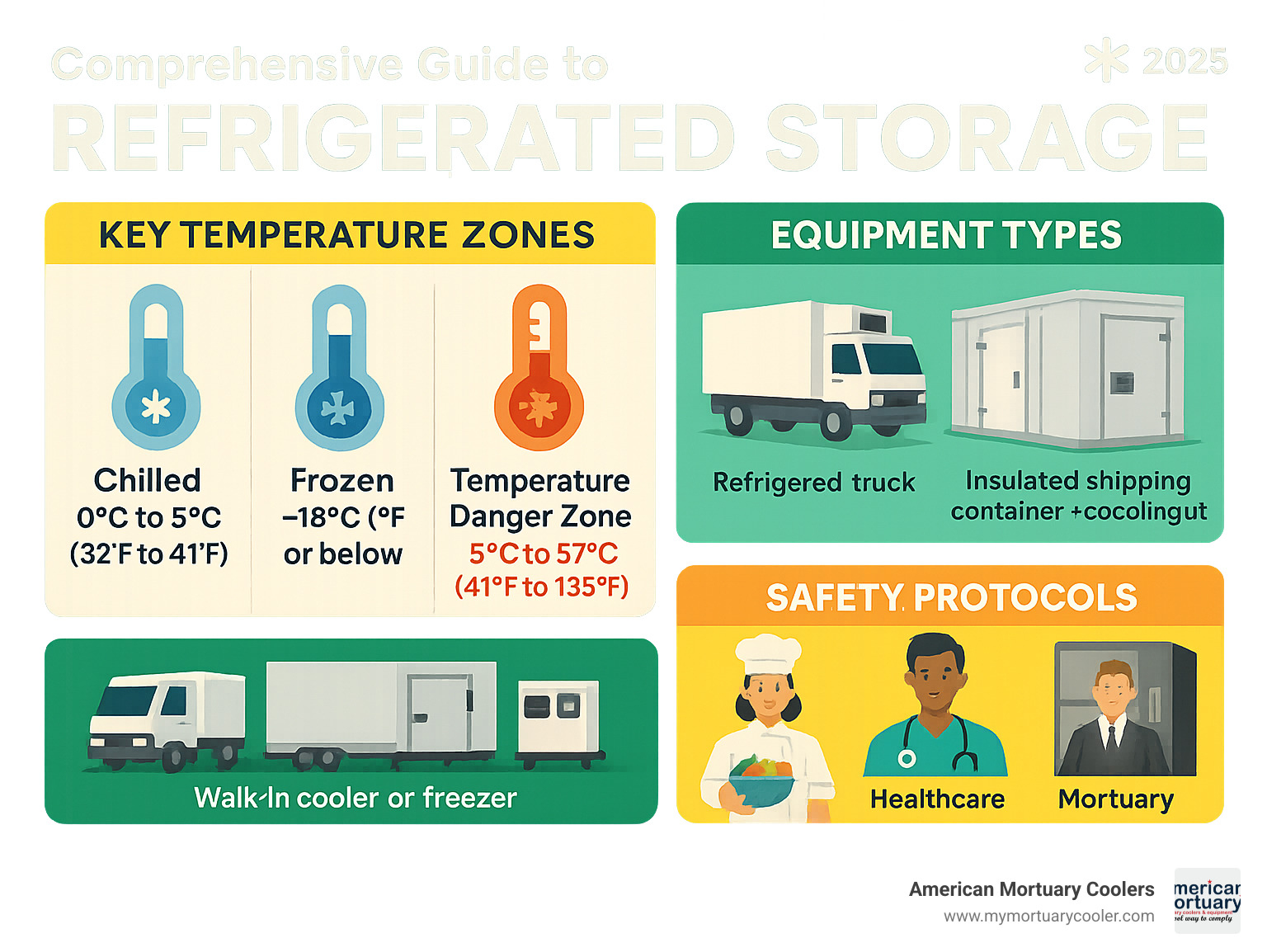

Key Refrigerated Temperature Zones:

- Chilled: 0°C to -5°C (32°F to 23°F) - fresh produce, dairy, prepared foods

- Frozen: -18°C (0°F) or below - long-term storage of meat, seafood, ice cream

- Temperature Danger Zone: 41°F to 135°F - where harmful bacteria multiply rapidly

Main Types of Refrigerated Equipment:

- Refrigerated trucks and trailers (reefers)

- Insulated shipping containers with cooling units

- Walk-in coolers and freezers for storage

- Specialized vehicles for pharmaceuticals and sensitive cargo

The global refrigerated transport market moves everything from fresh strawberries to life-saving vaccines. Without proper temperature control, perishable goods worth billions of dollars would spoil before reaching consumers.

Modern refrigerated containers can maintain temperatures from -65°C to 40°C (-85°F to 104°F), enabling year-round access to fresh produce worldwide.

As Mortuary Cooler, I've spent years helping funeral homes and medical facilities choose the right refrigerated storage solutions for their specific needs. My experience with refrigerated systems extends from basic walk-in coolers to specialized mortuary equipment that meets strict regulatory standards.

Quick refrigerated terms:

The Origins & Meaning of "Refrigerated"

Ever wonder where the word "refrigerated" comes from? The term traces back to the Latin word refrigeratus, which simply means "to cool" or "to make cold." According to Merriam-Webster, people first started using "refrigerate" way back in 1534 - centuries before anyone figured out how to actually do it well.

Back then, keeping things cold was a real challenge. The science behind refrigerated storage is straightforward: remove heat from a space to slow down bacteria and keep food fresh longer. But without modern technology, people had to get creative.

The early solution? Ice harvesting. During winter months, workers would cut massive blocks of ice from frozen lakes and rivers. They'd store these blocks in insulated buildings packed with sawdust, then use the ice year-round to keep food cold.

Everything changed in 1925 when Frederick McKinley Jones, a brilliant American inventor, developed the first successful mechanically refrigerated truck. He initially designed it for the ice cream industry, but this innovation completely revolutionized how we move food around the country.

Key Milestones in Refrigeration History

The 1870s brought us ice cars - railroad cars cooled with harvested ice that could ship meat from coast to coast for the first time. Before this, you could only eat what was raised locally.

By the 1880s, engineers had figured out ammonia-based mechanical refrigeration systems. These were the first truly reliable cooling systems that didn't depend on natural ice.

The 1920s saw domestic refrigerators finally become available to regular families. At first, they were luxury items that only wealthy households could afford.

The real game-changer came in the 1960s with standardized refrigerated containers - what we call "reefers" today. These containers could move seamlessly from ships to trains to trucks, creating the global cold chain that brings us fresh food from around the world.

From those early ice-filled railroad cars to today's high-tech systems, refrigeration has come an incredible distance. Modern units can maintain banana shipments at precisely +14.4°C (57.9°F) for optimal ripeness, or keep life-saving vaccines at exact temperatures during transport across continents.

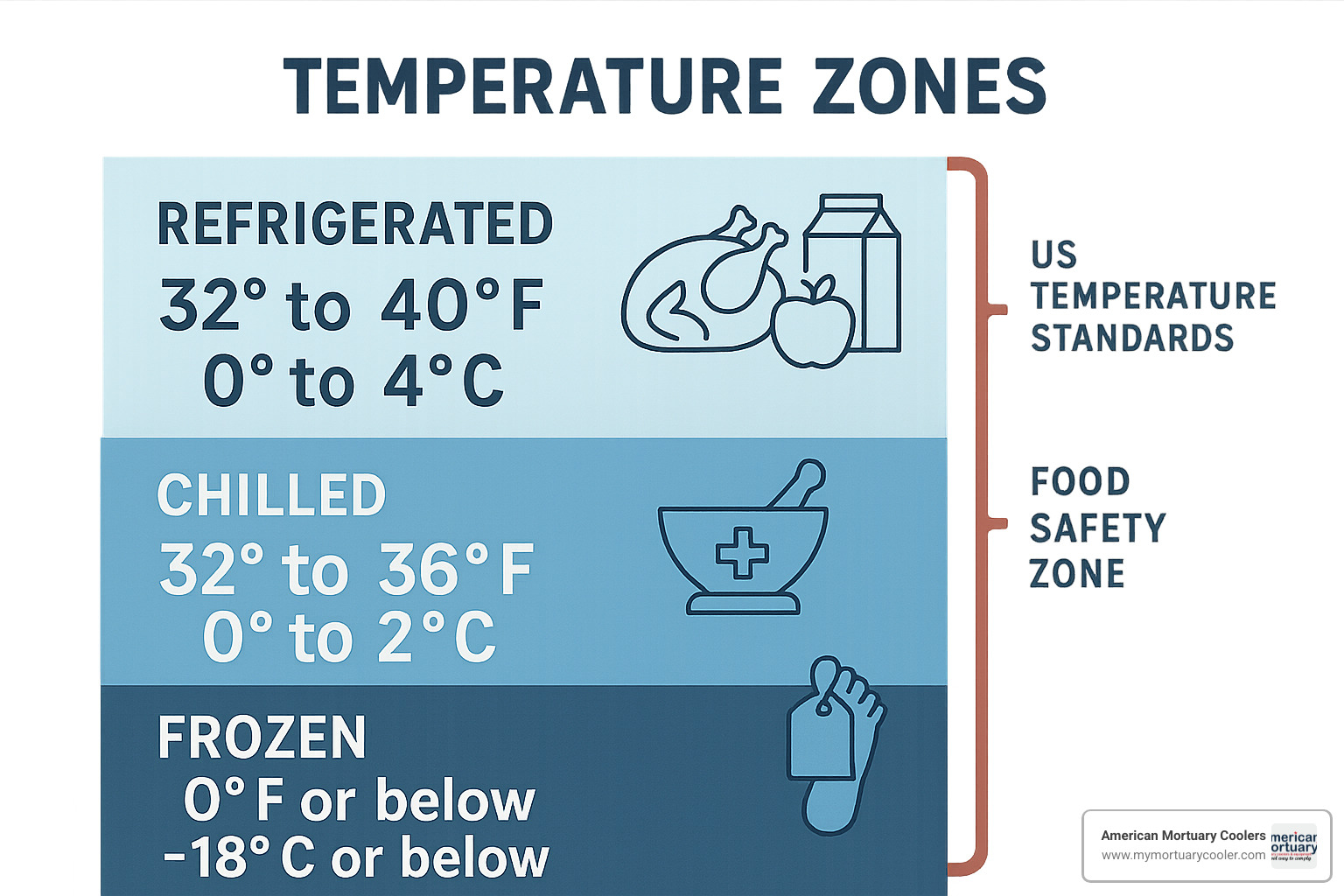

Understanding Refrigerated, Chilled & Frozen Storage

When you're working with refrigerated products, understanding temperature zones can mean the difference between safe food and a trip to the emergency room. The infamous temperature danger zone sits between 41°F and 135°F - this is where bacteria multiply rapidly.

Chilled storage operates between 0°C to -5°C (32°F to 23°F), which is perfect for fresh produce, dairy products, and prepared meals. This range slows bacterial growth without freezing, keeping your strawberries from turning mushy while maintaining their nutritional value. Most chilled foods stay fresh for 3 to 14 days.

Frozen storage takes a different approach entirely. At -18°C (0°F) or below, bacterial growth stops completely - it's like hitting the pause button on spoilage. This is your go-to for long-term storage of meat, seafood, and prepared foods that need to last months or even years.

The UK chilled food market exploded from £173 million in 1988 to over £1,750 million in 2005, representing about 10% of all retail food value.

For specialized applications like Mortuary Freezers, temperature precision becomes even more critical. These systems often require redundant backup systems and continuous monitoring.

Why Time/Temperature Control for Safety (TCS) Foods Need to Stay Refrigerated

TCS foods are basically the high-maintenance foods of the storage world. They're packed with moisture and nutrients that bacteria absolutely love, which means they need constant temperature babysitting to stay safe.

Think about dairy products like milk, cheese, and yogurt - they're protein-rich and moist, making them perfect breeding grounds for harmful bacteria. The same goes for eggs and egg-based dishes, meat, poultry, and seafood, cooked vegetables and grains, and cut fruits and vegetables.

Here's where the math gets scary: bacteria can reach dangerous levels in just four hours when TCS foods sit between 41°F and 135°F. The two-hour rule is your safety net - never let TCS foods sit at room temperature for more than two hours. If it's over 90°F outside, that window shrinks to just one hour.

The four-hour discard rule is non-negotiable. If TCS foods have been in the danger zone for more than four hours total, throw them out.

Best Practices to Organize a Refrigerated Fridge at Home or Work

Organizing a refrigerated space isn't just about playing Tetris with your leftovers - it's about creating a system that keeps food safe and maximizes freshness.

Your top shelf should house ready-to-eat foods like leftovers and deli meats. Middle shelves work perfectly for dairy products and eggs, while lower shelves are reserved for raw meat, poultry, and seafood. This raw-to-ready hierarchy prevents dangerous cross-contamination.

Crisper drawers aren't just fancy storage - they're designed with specific humidity controls for fruits and vegetables. Don't waste that door space on milk though - it needs the coldest spots in your fridge.

The FIFO method (First In, First Out) keeps your food rotation smooth and waste-free. Date marking everything when it enters storage takes two seconds but can save you from eating mystery leftovers from three weeks ago.

Airflow is crucial for maintaining consistent temperatures. Don't pack shelves so tight that air can't circulate. A simple thermometer in your fridge can save you from temperature guesswork. Most home refrigerators should stay between 35°F and 38°F for optimal food safety.

Refrigerated Transport: Vehicles, Containers & Best Practices

The world of refrigerated transport is bigger than most people realize. Right now, about 4 million refrigerated vehicles are moving goods across the globe - from tiny insulated vans delivering fresh flowers to massive container ships carrying frozen seafood across oceans.

The backbone of this system is the refrigerated container, or "reefer" as industry folks call them. These remarkable boxes can maintain temperatures anywhere from a bone-chilling -65°C to a toasty 40°C (-85°F to 104°F). That's precise enough to keep ice cream frozen solid or maintain bananas at the perfect ripeness temperature during a three-week ocean voyage.

Refrigerated containers get their power from different sources depending on where they are. When sitting on a ship or at a port, they plug into electrical connections called reefer points. But when they're rolling down the highway on a truck, they rely on diesel generator sets to keep the cooling units running.

For really specialized cargo, some companies use cryogenic refrigeration systems. These use dry ice or liquid nitrogen instead of traditional refrigeration. A dry ice container can keep things cold for about 100 hours during air freight, while liquid nitrogen systems can maintain temperature for up to 17 days on rail or 30 days at sea - all without any external power source.

Picking the Right Refrigerated Vehicle for Your Cargo

Choosing the right refrigerated vehicle isn't just about size - it's about matching your specific needs to the right technology.

Insulated vans are the workhorses of local delivery. They don't have their own refrigeration units, so they rely on pre-cooling your products and thick insulation to maintain temperature. They're perfect for bakeries delivering fresh bread or florists moving flowers across town.

Chiller conversion vans step things up with basic refrigeration units attached to insulated cargo areas. These can maintain temperatures between 0°C to 5°C (32°F to 41°F), making them ideal for dairy deliveries, fresh produce, or regional routes up to about 200 miles.

Semi-freezer vans offer more flexibility with improved refrigeration systems and quick-defrost mechanisms. These units can handle both chilled and frozen goods, often with multi-zone temperature control.

Full-freezer vans are built for the long haul with frozen goods. They maintain temperatures from -18°C to 0°C (0°F to 32°F) and feature thicker insulation and heat-resistant doors.

When making your choice, consider your cargo volume, distance, and how precise your temperature control needs to be. A standard 53-foot reefer trailer can hold up to 26 pallets, while smaller vans give you better maneuverability in tight urban spaces.

Operating Tips to Keep Loads Safely Refrigerated on the Road

Running a successful refrigerated transport operation is all about the details.

Pre-cooling is absolutely critical. Start cooling your container at least 20 minutes before loading - preferably longer. The refrigeration unit needs time to bring the internal temperature down and stabilize.

When you're ready to load, turn off the refrigeration unit's fan during the loading process. This prevents warm outside air from being pulled into the container.

Proper spacing makes all the difference for airflow. Leave 1-2 inches from the sidewalls, 9 inches from the ceiling, and 4 inches from the rear doors. Use pallets and air chutes to ensure air can flow under and around your products.

During transport, modern systems let you monitor temperature, GPS location, door status, and fuel levels in real-time. This technology has been a game-changer for preventing spoilage and maintaining quality control.

Load and unload quickly. Every minute those doors are open, you're fighting against outside temperature and humidity. The goal is simple: maintain the cold chain from start to finish.

Safe Storage, Emergency Preparedness & Power-Outage Plans

When the power goes out, time becomes your enemy. Your refrigerated goods start warming up the moment electricity stops flowing, but don't panic - you've got more time than you might think.

A closed refrigerator will stay cold for about 4 hours during a power outage. Your freezer gives you even more breathing room - a full freezer maintains safe temperatures for approximately 48 hours, while a half-full freezer only stays cold for about 24 hours. The key word here is closed - every time you open those doors, you're letting precious cold air escape.

Smart preparation makes all the difference. Keep a backup thermometer handy so you can monitor temperatures without opening the main unit. Stock up on ice packs before storm season hits, and know where to get dry ice if you need it.

If you're running a business that can't afford to lose refrigerated inventory, a properly sized generator becomes essential equipment, not a luxury.

When power returns, don't just assume everything's fine. Check temperatures first, then examine your food carefully. Discard any perishable items that spent more than 2 hours above 40°F - it's not worth risking foodborne illness to save a few dollars.

Before restocking, clean and sanitize your refrigerated spaces thoroughly. Power outages often come with other issues like flooding or contamination, so a fresh start protects your new inventory.

For facilities requiring continuous cooling, investing in energy-efficient cooling systems with backup capabilities isn't just smart - it's essential business protection.

Handling Equipment Failure Without Spoiling Refrigerated Goods

Equipment doesn't always fail when it's convenient. But quick thinking and faster action can save thousands of dollars in refrigerated inventory.

The moment you find a failure, document everything - the time, temperature readings, and what you observe. Take photos with timestamps for insurance purposes. Then resist the urge to keep opening doors to check on things.

Get professional help immediately, but while you're waiting, start planning your next moves. Portable refrigeration units can be rented on short notice in most areas. If you've got other functioning units nearby, start prioritizing which items absolutely must stay cold.

For emergency cooling, dry ice works wonders, but handle it safely - it needs proper ventilation and protective equipment. Never put dry ice in a completely sealed container.

Temperature logs become your best friend during equipment failures. They show exactly when problems started and help with insurance claims later.

At American Mortuary Coolers, we've seen how devastating equipment failures can be for our customers. That's why we often recommend redundant refrigeration systems that automatically switch to backup units when primary systems fail. The funeral industry can't afford refrigeration failures - families depend on us during their most difficult times.

Innovation, Sustainability & Regulations in the Refrigerated World

The refrigerated industry is going through some exciting changes. We're seeing everything from solar-powered units keeping vaccines cold in remote villages to smart sensors that can predict when your freezer might break down before it actually happens.

The push toward sustainability isn't just feel-good marketing - it's driven by real regulations and genuine need. Take the Energy Independence and Security Act (EISA), which now requires R-29 insulation for coolers and R-32 for freezers. That translates to units that use significantly less energy to maintain the same temperatures.

Solar-powered refrigeration is particularly fascinating. Scientific research on solar refrigeration shows these systems can maintain consistent temperatures even in challenging conditions.

The regulatory landscape keeps everyone on their toes. The USDA FSIS governs how meat and poultry must be kept cold, while the FDA Food Code sets the standards for retail food storage. For international shipping, the International Maritime Organization (IMO) requires redundant refrigerated systems for hazardous cargo.

Low-global-warming-potential refrigerants are replacing older synthetic options. Natural refrigerants like CO2 and ammonia are making a comeback, which is ironic since they were among the first refrigerants ever used.

The UK's chilled prepared food market, valued at £13,126 million in 2018, shows how consumer demand drives innovation. People want fresh, convenient food options, and that requires increasingly sophisticated refrigerated storage and transport systems.

Future Trends: Smart Sensors & AI for Refrigerated Logistics

Smart sensors and AI are changing how we think about refrigerated logistics. Instead of just reacting to problems, we're moving toward systems that prevent them entirely.

Internet of Things (IoT) integration means your refrigerated truck can now tell you its temperature, humidity, door status, GPS location, fuel level, and engine performance - all in real-time. If something goes wrong, you know immediately.

Artificial intelligence takes this data and makes it useful. Predictive maintenance algorithms can analyze usage patterns and tell you to replace a compressor before it fails. Route optimization considers traffic, weather, and delivery windows to find the most efficient path.

Blockchain technology creates immutable temperature logs that satisfy regulatory requirements and provide complete supply chain transparency. Smart contracts can automatically trigger payments when deliveries arrive within specified temperature ranges.

At American Mortuary Coolers, we're already incorporating some of these technologies into our custom installations. The funeral industry has particularly strict requirements for temperature control and documentation, so these innovations aren't just convenient - they're essential for compliance.

These technologies are becoming more affordable and reliable every year. The next 5-10 years should bring even more exciting developments as the technology matures and costs continue to drop.

Frequently Asked Questions about Refrigerated Storage

People ask me about refrigerated storage all the time - from butter storage quirks to power outage panic. Here are the most common questions I get, along with practical answers that'll help you keep your food safe.

Does butter need to be refrigerated?

Store-bought salted butter that's been pasteurized can actually sit on your counter for 8-10 days without any safety issues. The combination of salt and pasteurization creates a hostile environment for harmful bacteria. Plus, that high fat content naturally inhibits bacterial growth.

But homemade butter or unsalted varieties should always stay refrigerated because they don't have those same protective factors. And if you live somewhere hot or you're not planning to use that butter stick within a week, just pop it in the fridge.

How long do refrigerated foods stay safe during a power outage?

Your refrigerator will keep things cold for about 4 hours if you resist the urge to peek inside. Every time you open that door, you're letting precious cold air escape.

Freezers are much more forgiving. A full freezer will maintain safe temperatures for approximately 48 hours, while a half-full freezer gives you about 24 hours. The more stuff you have packed in there, the longer it stays cold.

If you're looking at a longer outage, start thinking about backup plans. Ice from the store, coolers, or even asking neighbors with generators if they have spare refrigerated space can save your groceries.

What's the difference between a refrigerated truck and a reefer container?

A refrigerated truck is basically what it sounds like - a truck with a built-in cooling system. The driver controls both the vehicle and the temperature settings. These are perfect for regional deliveries where you need to get from point A to point B on roads.

A reefer container, on the other hand, is more like a refrigerated shipping box that can travel by truck, train, or ship. It doesn't have its own engine - instead, it plugs into external power sources like ship electrical systems or diesel generators. These containers are the workhorses of international trade.

The choice really comes down to your logistics needs. If you're shipping internationally or need that intermodal flexibility, containers are your friend. If you're making direct deliveries within driving distance, trucks give you more control and convenience.

At American Mortuary Coolers, we understand that temperature control isn't just about food - it's about maintaining dignity and safety in sensitive situations.

Conclusion

The story of refrigerated systems is really the story of human progress itself. From those first Latin speakers using "refrigeratus" to describe making things cold, to today's smart containers that can text you when something goes wrong - we've come a long way.

Every time you grab milk from your fridge or enjoy fresh strawberries in winter, you're benefiting from centuries of innovation. The cold chain connects farmers in California to families in Maine, vaccine manufacturers to rural clinics, and funeral homes to the families they serve during difficult times.

The fundamentals haven't changed much though. That temperature danger zone between 41°F and 135°F is still your enemy - bacteria don't care how fancy your equipment is. Keep things cold, move them fast, and when in doubt, throw it out.

What's exciting is where we're heading. Solar-powered reefer units are already hauling produce across sunny states. AI systems are predicting equipment failures before they happen. Low-impact refrigerants are helping us cool things down without heating up the planet.

At American Mortuary Coolers, we've spent years learning that every industry has its own refrigerated storage challenges. What works for a restaurant doesn't work for a medical facility. What's perfect for a grocery store won't cut it for a funeral home. That's why we build custom solutions.

Our Tennessee-based team has delivered cooling systems from coast to coast, and we've learned something from every installation. Whether it's dealing with humid Southern summers or dry Western heat, we know how to keep things at exactly the right temperature.

The refrigerated world touches everything. Your morning coffee creamer, the flowers at your local shop, even the specialized storage needs of medical and funeral facilities - it all depends on keeping things cold when they need to be cold.

Understanding refrigeration isn't just useful - it's essential. Whether you're running a business, planning for emergencies, or just trying to keep your family's food safe, these principles matter.

The cold chain keeps our modern world running smoothly. By respecting temperature requirements and following best practices, we all play a part in keeping it strong.

Want to learn more about how modern cooling technology can work for your specific needs? Check out our guide on energy-efficient cooling systems - you might be surprised by what's possible these days.