A Quick Start Guide to Downloading Fridge Revit Families

Why Fridge Revit Families Are Essential for Modern BIM Projects

A fridge revit family is a parametric 3D model of a refrigerator that integrates seamlessly into Autodesk Revit projects, providing accurate dimensions, materials, and coordination data for architectural and MEP design work.

Quick Answer for Fridge Revit Family Users:

- What it is: Parametric refrigerator model (.rfa file) with adjustable dimensions and materials

- Where to find: RevitCity (40+ models), BIMsmith Market, manufacturer websites

- Key benefits: Accurate space planning, MEP coordination, automated scheduling

- Best practices: Choose appropriate LOD, verify file size, match project requirements

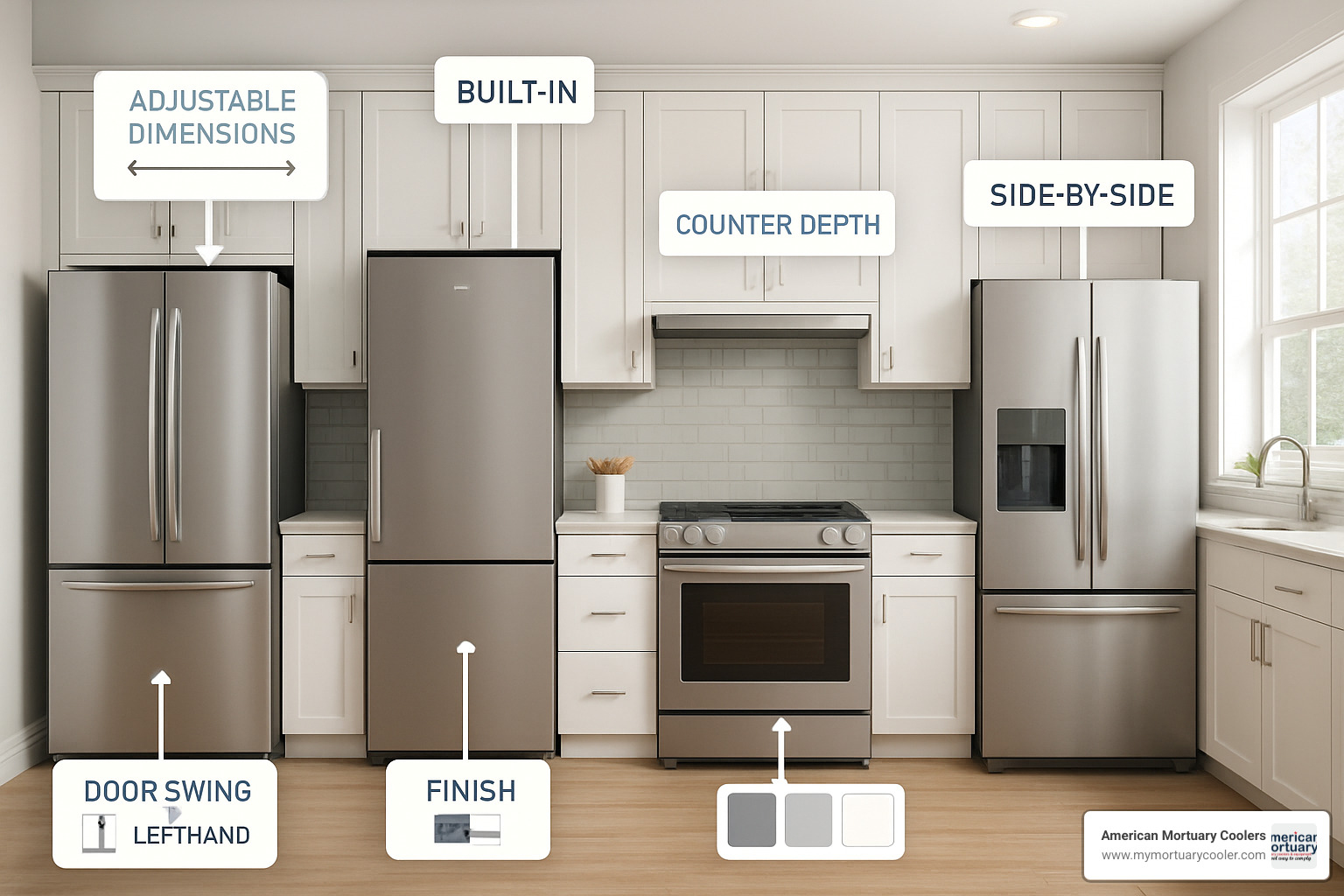

- Common types: French door, side-by-side, built-in, commercial units

The kitchen is one of the most significant parts of any project, and refrigerators represent critical coordination points between architectural layouts and MEP systems. With over 40 different fridge Revit family objects available on RevitCity alone - including the Fisher & Paykel French Door model that's been downloaded nearly 49,000 times - these digital assets have become essential tools for modern BIM workflows.

Why does this matter for your projects? Incorrectly sized or poorly detailed refrigerator families can lead to coordination conflicts, inaccurate material takeoffs, and costly field changes. Whether you're working on residential kitchens, commercial food service areas, or specialized facilities, having the right fridge Revit family saves time and prevents errors.

Modern parametric families allow you to adjust width, depth, height, door swing directions, and finish materials - all while maintaining accurate clearance zones and connection points for utilities. This flexibility means one well-made family can serve multiple project types and design iterations.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in commercial refrigeration and BIM coordination. Having worked with countless fridge revit family models for specialized cooling applications, I understand the critical importance of accurate 3D modeling in facility design and equipment specification.

Quick look at fridge revit family:

What Is a Revit Family & Why It Matters for Kitchen Appliances

Think of a Revit family as a smart building block that knows how to behave. Unlike those static CAD drawings we used to wrestle with, these parametric objects carry intelligence about materials, dimensions, electrical needs, and even maintenance schedules.

When it comes to kitchen appliances, this intelligence becomes your best friend. A properly built fridge revit family doesn't just plop a rectangle where your refrigerator goes. It understands clearance requirements, electrical connections, and ventilation needs - all the details that can make or break your coordination meetings.

The real magic happens with parameters. Need to switch from a 30-inch wide model to a 36-inch? Change one setting. Want stainless steel instead of black? Another quick adjustment. Flip the door swing direction? Done in seconds. One family file can handle dozens of variations without cluttering your project library.

At American Mortuary Coolers, we've seen how this flexibility transforms commercial refrigeration projects. The same parametric approach that works for residential kitchens scales beautifully to walk-in coolers and specialized equipment.

Choosing the Correct Revit Category for Fridges

Here's where many projects stumble right out of the gate. Dropping your refrigerator into the wrong Revit category creates headaches that ripple through your entire team. Most residential fridges belong in Specialty Equipment, though built-in units sometimes fit better under Casework depending on your office standards.

Commercial refrigeration gets trickier. Walk-in coolers and freezers typically live in Specialty Equipment, but we've worked with firms that prefer custom categories for better project organization. The key is consistency across your discipline matrix.

Your architectural team focuses on space planning and finishes. Meanwhile, MEP engineers need those electrical loads and connection points. A properly categorized fridge revit family serves both groups without stepping on anyone's toes.

Equipment category works for most residential units, while plumbing fixtures might seem logical but usually causes more confusion than clarity. Casework makes sense for built-in models that integrate with cabinetry. The discipline matrix approach helps everyone stay on the same page throughout the project lifecycle.

Key Benefits of Using a Fridge Revit Family

Accurate geometry saves embarrassing field moments. When your fridge revit family shows exact dimensions, you won't find that 36-inch refrigerator won't squeeze through a 35-inch doorway. Those clearance calculations become automatic and reliable.

Clash detection transforms from guesswork into precision. Proper connector points for electrical and water lines let Revit spot conflicts with structural elements or MEP components before anyone picks up a hammer. No more surprise findies during rough-in.

Scheduling capabilities eliminate double work. Instead of manually typing refrigerator specifications into separate spreadsheets, the family parameters automatically populate equipment lists, energy calculations, and maintenance databases. Change the model number once, and it updates everywhere.

For facility management, this data continuity pays dividends for decades. The same family that helped design the kitchen becomes part of the building's digital twin. Maintenance teams can access manufacturer data, warranty information, and replacement schedules directly from the model.

Multi-trade coordination flows naturally when everyone works from the same intelligent objects. Electrical rough-in aligns with the appliance connection points. Ventilation calculations use actual equipment specifications. Cabinet installers know exact clearance requirements. The fridge revit family becomes the single source of truth that keeps all trades synchronized.

How to Choose and Customize a Fridge Revit Family

Selecting the perfect fridge revit family feels a bit like shopping for an actual refrigerator - you need to know what you're looking for before you start browsing. The key difference? Digital families can transform to meet your exact needs with just a few parameter adjustments.

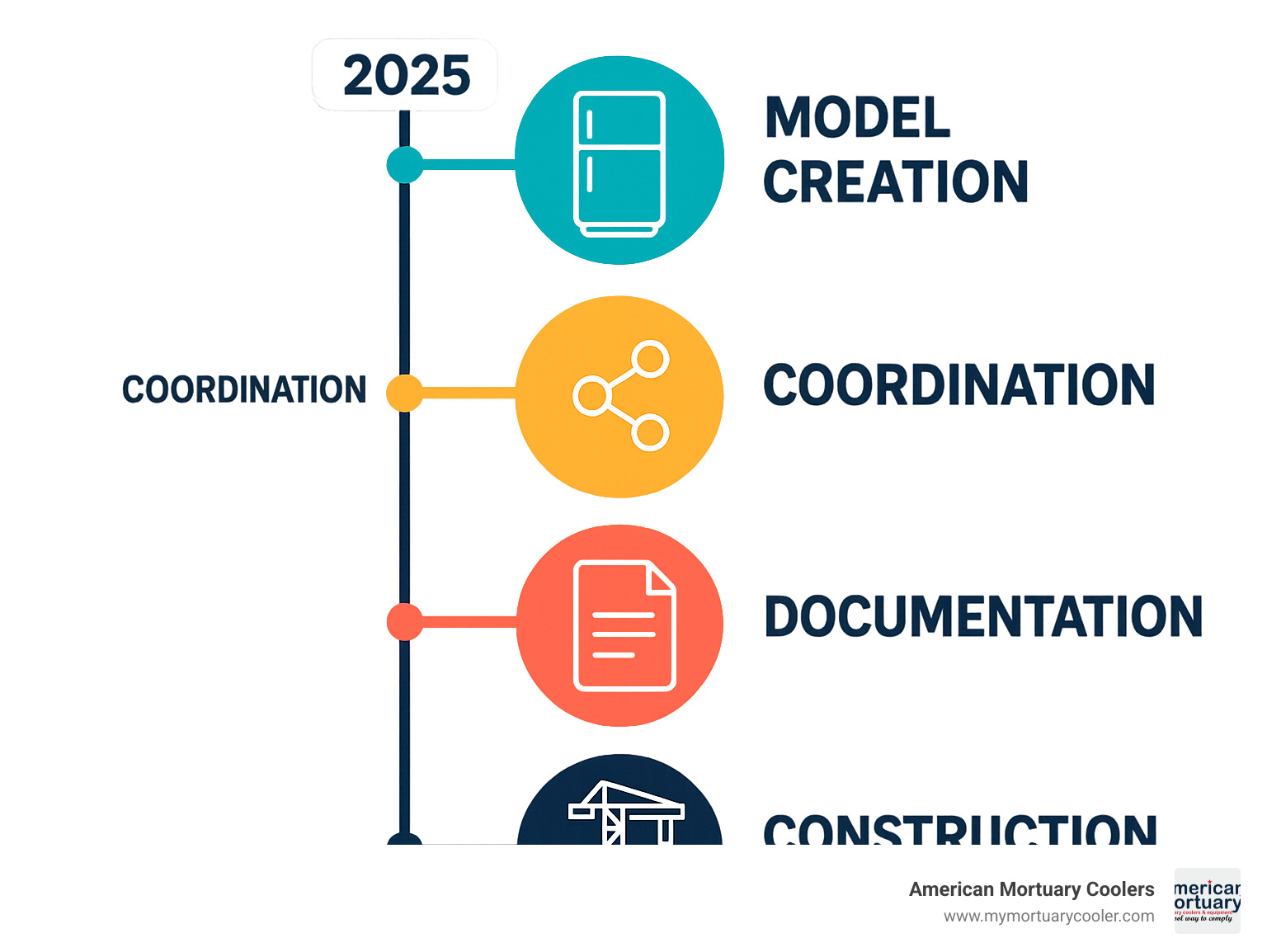

Your project phase drives everything. During schematic design, you'll want generic families that focus on overall proportions and space planning. These nimble files load quickly and won't bog down your model while you're still figuring out the kitchen layout.

But when construction documents roll around, it's time to get specific. Manufacturer families become essential because contractors need exact dimensions, connection details, and finish specifications. Yes, these files are larger, but the accuracy is worth the trade-off.

Parameters make the magic happen. Width, depth, and height are the obvious ones, but the best families go much deeper. Look for door swing direction controls that let you flip between left-hand and right-hand openings. Finish materials should include the full range - stainless steel, black stainless, white, and even wood panel options for built-in units.

Handle styles might seem like a small detail, but they affect both appearance and clearances. Some families include internal configuration parameters that switch between French door, side-by-side, and top-freezer layouts within the same file.

Type catalogs are your best friend here. Instead of manually tweaking dimensions for every appliance, good families include pre-configured sets that match real products. Click "30" French Door" and boom - all the parameters adjust automatically to match actual manufacturer specifications.

| Feature | Generic Families | Manufacturer Families |

|---|---|---|

| File Size | Small (under 1MB) | Larger (2-5MB) |

| Detail Level | Basic proportions | Exact specifications |

| Flexibility | High dimensional flexibility | Limited to actual models |

| Best For | Early design phases | Construction documents |

| Parameter Count | 5-10 basic parameters | 20+ detailed parameters |

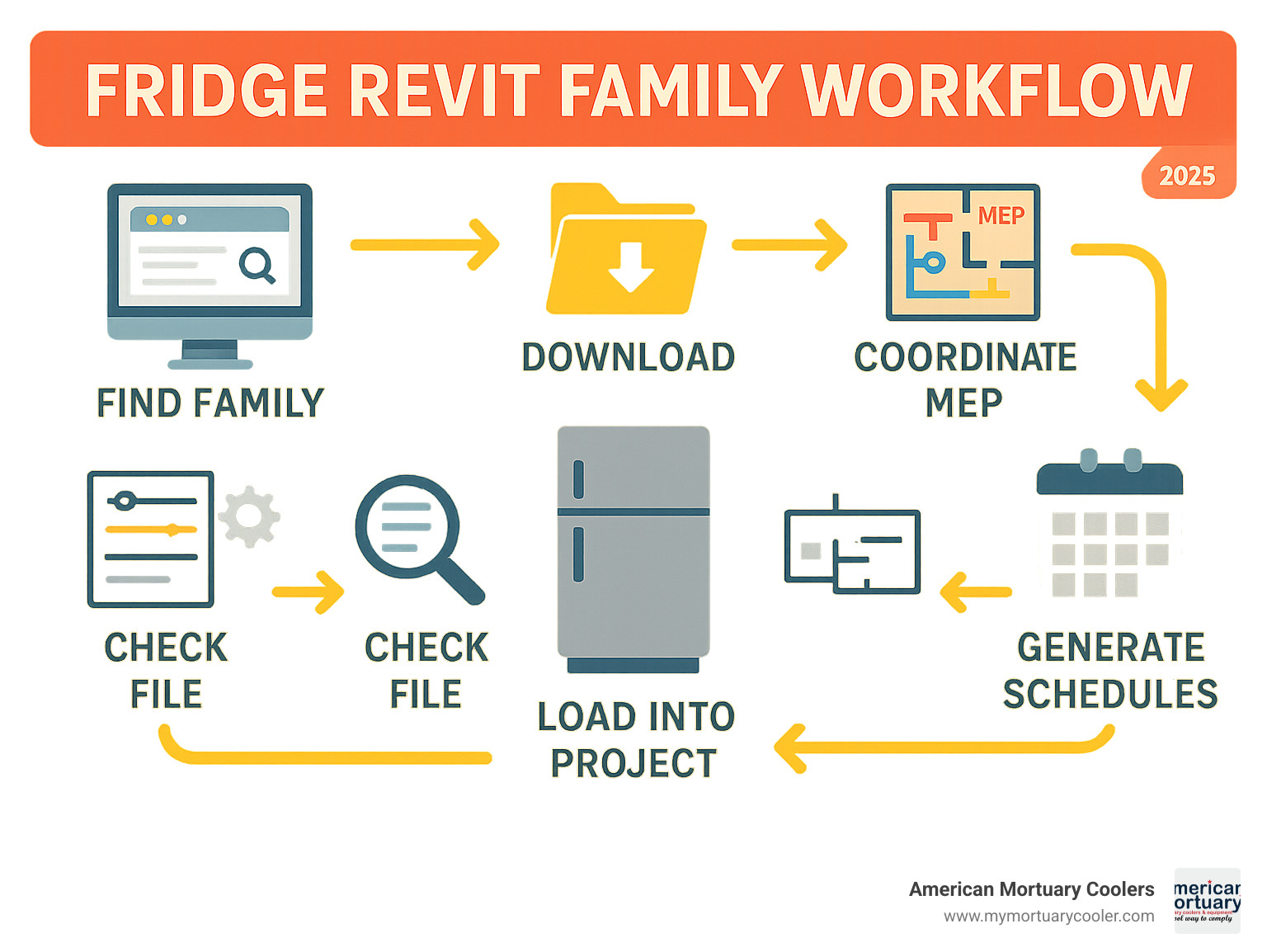

Downloading Your First Fridge Revit Family Step-by-Step

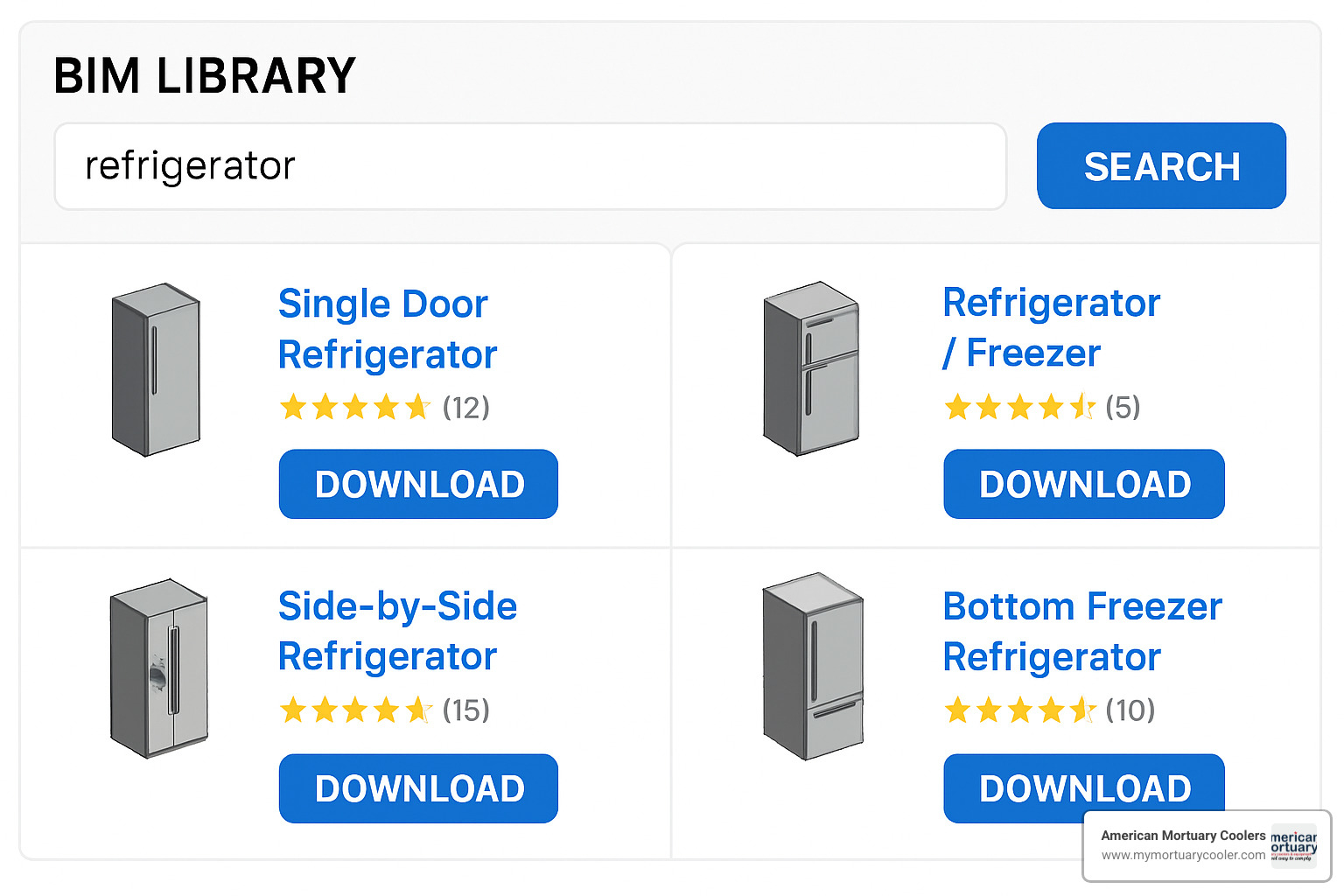

Let's grab your first fridge revit family from RevitCity, where refrigerators consistently rank among the most downloaded objects. With over 23,000 families available, you'll have plenty of options.

Start by browsing RevitCity's refrigerator section. The download counts tell a story - that Fisher & Paykel French Door model with nearly 49,000 downloads didn't get popular by accident. Check the user ratings and read the comments to avoid families with known issues.

Before clicking download, review the family details carefully. Revit version compatibility matters - don't grab a 2024 family for your 2019 project. File size gives you a hint about detail level. A 500KB family is probably basic geometry, while a 3MB file likely includes detailed hardware and materials.

The Free Refrigerators Revit Download – Kenmore French Door from BIMsmith Market offers excellent parametric controls with multiple finish options. For additional variety, browse the fridge Archives • Designs CAD collection, which includes options with multilingual tags for international projects.

Once downloaded, always test the .rfa file in a scratch project first. Load it up, cycle through the parameters, and check how materials render. Better to find problems now than during a client presentation.

Optimizing a Fridge Revit Family for Coordination

Raw downloaded families rarely work perfectly out of the box. A little optimization transforms a basic fridge revit family into a coordination powerhouse that plays nicely with your entire BIM workflow.

Shared parameters keep your team synchronized. When everyone uses the same parameter names for electrical loads and water connections, scheduling happens automatically. No more manually typing appliance specifications into separate spreadsheets.

Get the electrical loads right from the start. Residential fridges typically draw 3-5 amps, but don't guess - check the actual specifications. Commercial units can demand 20-30 amp circuits, and getting this wrong creates expensive field changes.

Water line connectors need precise placement for units with ice makers or water dispensers. The connection point should sit 6-8 inches above the floor, centered behind the unit. Miss this detail and your plumber won't be happy.

Nested families handle complex components neatly. Instead of modeling every ice maker detail in the main family, nest a separate ice maker family that can be toggled on or off. This approach keeps file sizes manageable while providing detailed coordination data where needed.

Visibility settings control what appears in different views. Floor plans show the outline and door swing for space planning, while 3D coordination views display full detail including clearance zones and connection points. Smart visibility keeps your drawings clean and your models fast.

At American Mortuary Coolers, we've learned that proper family optimization prevents coordination headaches down the road. Whether you're working with residential appliances or specialized commercial refrigeration, these optimization steps ensure smooth project delivery.

Where to Find High-Quality Fridge Revit Families Online

The landscape of BIM libraries has expanded dramatically. RevitCity remains the granddaddy of free content, with its 49,000+ downloads of popular models proving the community's trust in their curation.

BIMsmith Market offers manufacturer-verified content with detailed specifications. Their refrigerator families include accurate electrical loads, clearance requirements, and finish options that match actual products.

Manufacturer portals provide the most accurate families but with varying quality. Some manufacturers invest heavily in BIM content, while others offer basic geometry with minimal parameters.

The Refrigerators - BIM objects and Revit families from NBS Source provides UK-focused content with detailed specifications and compliance information.

For specialized applications like mortuary refrigeration, manufacturer-specific families become essential. At American Mortuary Coolers, we provide detailed BIM content for our walk-in units because generic families can't capture the specialized requirements of mortuary cooling systems.

Evaluating File Quality Before You Click Download

File size tells a story about family complexity. A residential fridge revit family should typically be 500KB to 2MB. Anything larger might include unnecessary detail that slows down your project.

Revit version compatibility matters more than you might think. Families created in newer versions can't be opened in older software, but the reverse usually works. Check the version requirements against your project standards.

Level of Development (LOD) should match your project phase. LOD 200 families work for schematic design, while LOD 350-400 families are needed for construction documents and coordination.

User ratings and comments provide real-world feedback. Look for families with multiple positive reviews and comments about successful project use. Avoid families with reports of missing materials or parameter conflicts.

Naming standards affect long-term project management. Well-named families follow consistent conventions like "ApplianceRefrigeratorFrench Door_36W" rather than cryptic codes or manufacturer part numbers.

Integrating Fridge Revit Families into Your BIM Workflow

Getting your fridge revit family to play nicely with the rest of your BIM workflow takes some planning, but the payoff is huge. Think of it like organizing your kitchen - everything has its place, and when done right, the whole system works smoothly.

Workset assignment is your first decision point. Kitchen equipment typically lives on a shared workset that multiple team members can access without stepping on each other's toes. This keeps the architects happy while letting the MEP engineers add their connection details.

Hosted placement versus non-hosted placement affects how your refrigerator behaves when things change. Most fridges should be floor-hosted, which means they automatically adjust when floor levels change. This is especially important in multi-story projects where floor heights might vary slightly between levels.

Clearance zones need representation in your model, whether built into the family or added separately. Door swing clearances are obvious, but don't forget about ventilation requirements and service access. Nobody wants to find during construction that the fridge door can't open because of a wall cabinet.

Render materials can make or break your client presentations. A fridge revit family with generic gray materials looks unprofessional in visualization. Take time to apply realistic materials that match actual product finishes - stainless steel, black appliance paint, or custom panel materials.

Schedule integration transforms how you handle equipment management. When your fridge families include proper parameters, they automatically populate equipment schedules, energy calculations, and maintenance databases. This eliminates the tedious manual data entry that nobody enjoys.

For specialized applications like walk-in coolers, this integration becomes even more valuable. Our experience at American Mortuary Coolers shows that detailed BIM families help facility managers understand maintenance requirements and replacement schedules years after construction. Check out our guide on Walk-In Cooler Options for more details on commercial refrigeration coordination.

Best Practices for Multidisciplinary Coordination

Architectural grids provide the foundation for clear equipment placement. Align your refrigerator families to grid intersections whenever possible. This makes coordination meetings much clearer - instead of saying "move it a little to the left," you can say "align to grid line B."

Structural framing coordination becomes critical for built-in units. That beautiful 48-inch wide built-in refrigerator might require structural modifications if it conflicts with standard framing layouts. Catch these conflicts early in the BIM model rather than in the field.

MEP connectors need accurate representation in your fridge revit family. Electrical connections should show up at the right height and amperage. Water supply lines for ice makers need proper sizing and location information. Drain connections for defrost cycles matter too, especially in commercial applications.

Clash tests should run automatically as part of your workflow. Set up clash detection rules that specifically check refrigerator clearances against walls, cabinets, and MEP components. The software can catch conflicts that human eyes might miss.

Parameter mapping ensures everyone speaks the same language. When architectural families use "Width" and MEP families use "Equipment Width" for the same thing, coordination becomes unnecessarily complex. Standardize parameter names across your family library.

Common Issues and How to Fix Them

Missing materials plague many downloaded families. The family loads fine but appears gray in renderings because material definitions got lost somewhere. Fix this by reassigning materials from your project's material library - it's tedious but necessary for professional presentations.

Category mis-assignment causes headaches with scheduling and visibility. A refrigerator that's accidentally categorized as "Furniture" won't show up in equipment schedules or respond to equipment-specific visibility settings. Always double-check category assignments when loading new families.

Heavy geometry can slow your project to a crawl. Some manufacturer families include excessive detail like internal compressor components that never appear in architectural drawings. Use the family editor to simplify geometry while keeping essential coordination information.

Parameter conflicts happen when multiple families use the same parameter names for different purposes. This creates confusion and potential errors in schedules. Establish and maintain consistent parameter naming standards across your family library.

Purging unused elements should be part of your regular maintenance routine. Downloaded families often bring along unused materials, line styles, and fill patterns that bloat your project file. Use Revit's purge tools regularly to keep things clean and fast.

The key to successful integration is thinking ahead about how each fridge revit family will be used throughout the project lifecycle. A little extra time spent on setup and standardization pays dividends in smoother coordination and fewer surprises during construction.

Frequently Asked Questions about Fridge Revit Families

Let's tackle the most common questions we hear about fridge revit family files. These come up in almost every project, and getting the answers right can save you hours of frustration down the road.

What level of detail should a fridge family have at SD, DD, and CD?

The level of detail should match what you actually need at each project phase. It's tempting to use highly detailed families from day one, but that's like bringing a sledgehammer to hang a picture frame.

Schematic Design needs just the basics - think of it as a smart box that knows its size. Your fridge revit family should show overall dimensions and door swing clearances, nothing more. Keep these files under 500KB so they don't slow down your early design iterations. A simple rectangular form with basic parameters for width, depth, and height gets the job done perfectly.

Design Development is where things get more interesting. Now you need material representation and more detailed parameters. The stainless steel finish matters for your renderings, and the exact door configuration affects your kitchen layout. This is when you start caring about whether it's a French door or side-by-side model.

Construction Documents demand the real deal - manufacturer-specific accuracy with exact dimensions, connection points, and electrical loads. Your contractor needs to know precisely where that water line connects and how many amps the unit draws. This is where those detailed manufacturer families really shine, even if they're larger files.

How do fridge Revit families affect overall project file size?

Individual fridge revit family files typically range from 200KB for basic generic units up to 5MB for those highly detailed manufacturer models with every bolt and screw modeled. In a typical residential project with 10-20 appliances, you're looking at maybe 5-20MB total - not huge in today's world of gigabyte project files.

The real performance impact comes from geometry complexity in your 3D views. Those beautifully curved door handles and detailed internal components can make your model feel sluggish when you're trying to steer around. It's like having too many apps running on your phone - everything just feels slower.

Here's what we've learned from years of working with complex refrigeration equipment: monitor your file performance using Revit's built-in tools. If your appliance families are causing slowdowns, create simplified versions for everyday working views and keep the detailed versions for presentation drawings and coordination meetings.

Can I convert a SketchUp or DWG refrigerator into a usable Revit family?

This question comes up constantly, especially when someone finds the perfect refrigerator model in the wrong format. The short answer is yes, but it's rarely worth the effort unless you're dealing with highly specialized equipment.

SketchUp models can be imported into Revit family templates, but they arrive as dumb geometry - no parameters, no intelligence, just triangulated surfaces that don't know how to behave. You'll spend hours cleaning up the geometry, adding parametric controls, and assigning proper materials. It's like trying to teach a statue how to dance.

DWG blocks work better as reference geometry for creating new families from scratch. You can trace the 2D linework to create proper Revit geometry with parametric controls. This approach gives you clean, efficient families that actually work the way Revit expects.

For complex conversions, honestly consider hiring a BIM specialist. We've seen teams spend weeks trying to convert a single complex family when a professional could create a better one from scratch in a day or two. Sometimes the smart move is knowing when to call in the experts.

At American Mortuary Coolers, we create our own fridge revit family files for our specialized equipment because generic families just can't capture the unique requirements of mortuary refrigeration systems. When you're dealing with specialized equipment, custom families aren't luxury - they're necessity.

Conclusion

Getting comfortable with fridge revit family downloads and integration really does make a difference in your BIM projects. Whether you're browsing through the 40+ options on RevitCity or downloading manufacturer-specific models with all the technical details, the family you choose touches every part of your project - from those early design meetings to facility management years down the road.

The key is keeping things practical. Match your family complexity to where you are in the project - simple boxes work great for schematic design, but you'll need detailed manufacturer models when contractors start asking specific questions. Always check file quality before committing to a family, because a bloated 10MB file will slow down everyone's work.

Consistency really pays off when you establish standard parameter names and categories across your team. When everyone speaks the same BIM language, coordination becomes so much smoother. And don't forget to test early with other disciplines - it's much easier to fix a clash in the model than on the construction site.

Keep your family library organized with regular cleanup and updates. Those unused materials and outdated families add up faster than you'd think.

Here at American Mortuary Coolers, we've learned that specialized refrigeration needs specialized BIM content. While most architects work with residential kitchen appliances, our world of commercial cooling systems requires families that capture unique requirements like temperature monitoring, specialized drainage, and heavy-duty electrical connections.

Whether you're placing a standard residential refrigerator or designing around a walk-in cooler, accurate 3D modeling prevents those expensive surprises that nobody wants to deal with. For deeper insights into commercial refrigeration systems and their BIM requirements, take a look at our detailed guide: Everything You Need to Know About Walk-In Refrigeration Units.

The time you invest in quality fridge revit family content really does pay off throughout your entire project. From those initial space planning sessions through construction coordination and into facility management, these digital assets become the backbone of successful kitchen and food service design.

It's worth doing right the first time - your future self (and your project team) will thank you for it.