A Quick Start Guide to Commercial Freezer Repair Services

Why Commercial Freezer Repair Matters for Your Business

Commercial freezer repair is a critical service that keeps businesses running when refrigeration systems fail unexpectedly. Here's what you need to know:

Key Commercial Freezer Repair Facts:

- Average lifespan: 10-20 years with proper maintenance

- Common issues: Temperature fluctuations, frost buildup, unusual noises, door seal problems

- Repair vs. replace: Consider repair if unit is under 10 years old and repair costs are less than 50% of replacement

- Emergency service: Most repairs can be completed same-day to minimize downtime

- Energy impact: Commercial freezers consume 17,000-35,000 kWh annually

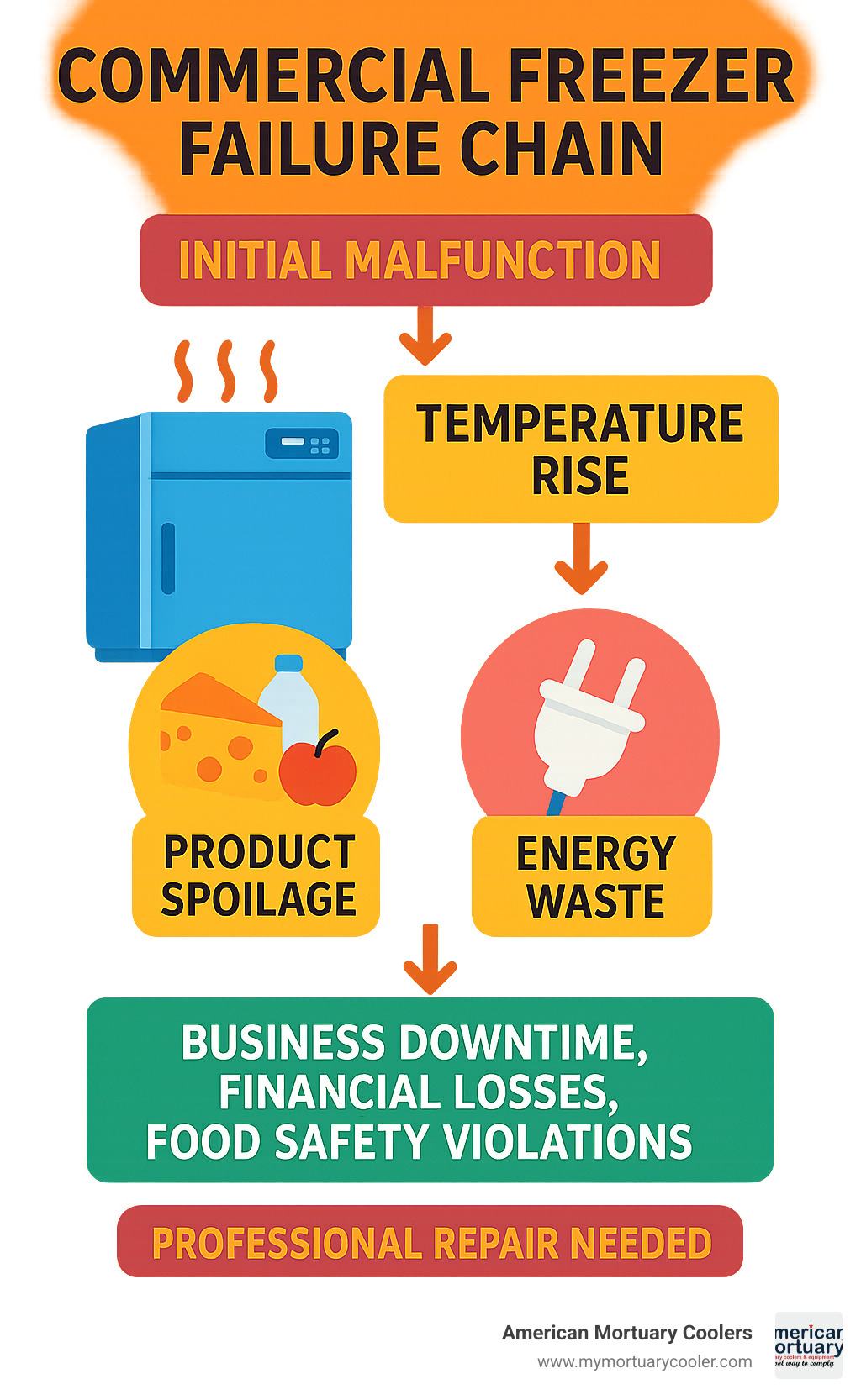

When your commercial freezer stops working, every hour counts. A malfunctioning freezer can lead to spoiled inventory, disrupted operations, and significant financial losses. According to USDA guidelines, perishable food items left in a warm refrigerator for four hours or more should be disposed of.

The most common signs you need repair include:

- Inconsistent temperatures or failure to maintain setpoint

- Excessive frost or ice buildup on coils

- Water leaks around the unit

- Strange noises from the compressor or fans

- Doors that won't seal properly

- Rising energy bills

Regular maintenance can significantly extend your freezer's lifespan and reduce the risk of costly breakdowns. Most commercial refrigeration repairs can be completed within the same day, minimizing business downtime.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in commercial freezer repair and cold storage solutions. Through my work with funeral homes and commercial facilities, I've seen how critical proper refrigeration maintenance is for business operations.

Quick commercial freezer repair definitions:

Understanding Your Commercial Freezer Fleet

When you walk into any busy commercial kitchen, you'll notice that commercial freezer repair needs vary dramatically depending on what type of equipment you're running. Understanding your freezer fleet isn't just about knowing what you have—it's about knowing what can go wrong and when.

Most commercial freezers have a lifespan of 10 to 20 years, but that range depends heavily on how hard you work them. A reach-in freezer in a busy restaurant kitchen might need attention after 8 years, while a walk-in unit in a slower-paced operation could run strong for two decades.

These workhorses consume between 17,000 and 35,000 kilowatt-hours annually. That's roughly equivalent to powering 1-3 average American homes for an entire year. When your freezer starts running inefficiently, those energy costs can climb fast.

For a deeper dive into maintaining your entire cold storage system, check out our complete guide to commercial cooler repair services.

What Is a Commercial Freezer?

Think of a commercial freezer as a heat-moving machine rather than a cold-making machine. It's constantly working to pull heat out of your products and dump that heat somewhere else—usually into your kitchen or outside.

The compressor acts like the heart of the whole system. It squeezes refrigerant gas and pumps it through a continuous loop. When this component fails, you're looking at one of the most expensive repairs possible. Most commercial compressors last about 10 years, but they'll tell you they're struggling long before they completely give up.

The evaporator coils do the actual cooling work inside your freezer. When these coils get covered in frost, they can't absorb heat properly. Your compressor ends up running constantly, trying to reach a temperature it simply can't achieve.

The condenser coils release all that captured heat to the outside world. When dust and grease coat these coils, heat transfer becomes nearly impossible. The compressor works overtime, energy bills skyrocket, and commercial freezer repair calls become inevitable.

Popular Freezer Types & Where They're Used

Reach-in freezers are the backbone of most restaurant kitchens and cafeterias. These tall, narrow units with swing-out doors give you quick access to ingredients without taking up much floor space.

Walk-in freezers are the heavy lifters of the commercial world. These room-sized units typically start around 15×15 feet, though they can be much larger. The compressors on these units often last about 15 years, making them a serious investment worth protecting.

Display freezers serve double duty in retail settings. They keep products frozen while showing them off to customers through glass doors and LED lighting.

Under-counter freezers maximize every square inch in cramped kitchens, while blast freezers handle specialized jobs in laboratories and food processing facilities. These powerful units can maintain temperatures down to -10°F.

At American Mortuary Coolers, we've seen how critical precise temperature control becomes in funeral homes. When you're entrusted with someone's loved one, there's absolutely no room for equipment failure.

When & Why You Need Commercial Freezer Repair

Your commercial freezer doesn't usually give you much warning before it decides to call it quits. One day it's humming along perfectly, and the next day you're staring at a puddle of water and wondering why your freezer sounds like a freight train.

Most freezer problems start small and gradually get worse. Temperature creep might begin with just a degree or two above normal. That innocent-looking frost buildup around the evaporator coils slowly gets thicker. Those odd noises from the compressor become a little louder each week.

The USDA's spoilage rule states that perishable food left in temperatures above 40°F for more than four hours should be thrown away. When your freezer starts failing, every minute counts. For detailed guidelines on keeping food safe during equipment failures, check out this Scientific research on food safety during outages.

Signs You Need Commercial Freezer Repair

Commercial freezer repair becomes absolutely critical the moment you notice these warning signs. Don't wait and hope things will get better on their own - they won't.

Temperature problems are usually your first clue that something's wrong. If your freezer can't hold its set temperature, or you notice some areas staying warmer than others, you're looking at anything from a simple thermostat issue to a dying compressor.

Door gasket wear might seem like a minor issue, but those rubber seals are working 24/7 to keep warm air out. When they start cracking or losing their grip, warm air sneaks in constantly. Your freezer works overtime trying to compensate, which shows up as higher energy bills and potential frost problems.

You'll know your gaskets are failing when you can slide a dollar bill out of a closed door without resistance. A properly sealed door should grip that bill firmly.

Excessive frost on your evaporator coils isn't just unsightly - it's a efficiency killer. Frost acts like a thick blanket, preventing proper heat transfer and blocking airflow. Your compressor runs constantly but can't keep up.

Water leaks around your unit signal serious trouble. Whether it's a clogged drain line or something more serious, standing water can damage your floors and create safety hazards.

Typical Causes of Malfunctions

Most commercial freezer repair calls fall into a few common categories. Understanding what typically goes wrong can help you spot problems early.

Refrigerant leaks are serious business. Not only do they prevent proper cooling, but they're also expensive to fix and potentially harmful to the environment.

Compressor failure is the big one - the repair that makes you seriously consider replacement instead. When compressors go bad, you'll usually hear unusual noises, notice the unit not cooling properly, or find that the compressor won't start at all.

Electrical problems can be tricky to diagnose but dangerous to ignore. Tripped breakers, faulty wiring, or failing electrical components can leave you without refrigeration and create fire hazards.

Defrost timer issues cause those frustrating frost buildup problems. Your freezer should defrost automatically once or twice daily. When the timer fails, ice accumulates until your evaporator coils look like they belong in Antarctica.

Same-Day Commercial Freezer Repair: What to Expect

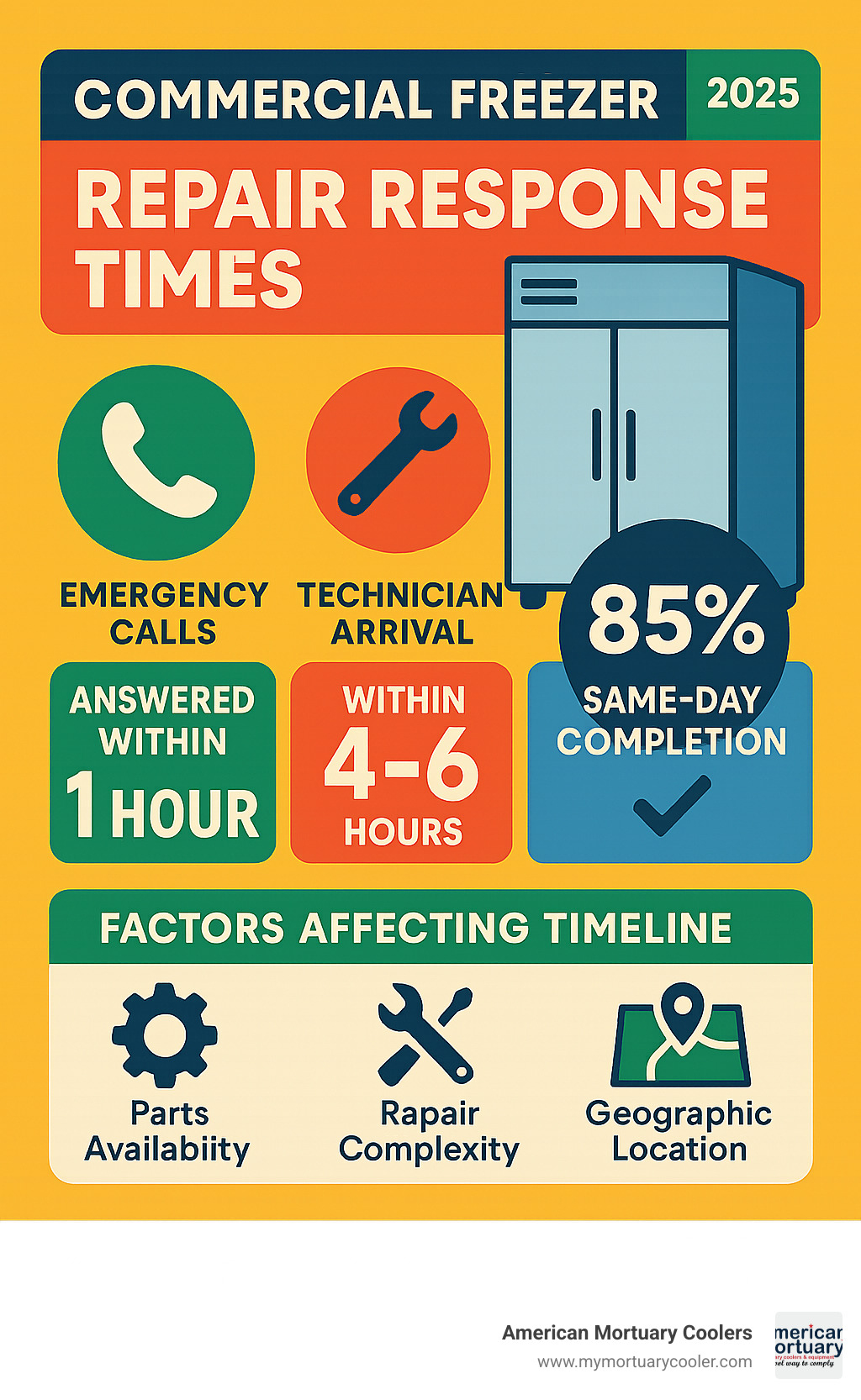

When you call for emergency commercial freezer repair, most reputable companies offer same-day service because they understand that every hour of downtime costs you money. You'll typically get a 3-hour service window with a call ahead to confirm timing.

Good repair companies stock their trucks with commonly needed parts - things like door gaskets, thermostats, fan motors, and basic electrical components. This means they can often complete repairs in one visit instead of ordering parts and coming back later.

Many services will waive the diagnostic fee when you authorize the repair work. This makes it more affordable to get a professional assessment of what's actually wrong with your freezer.

The Commercial Freezer Repair Process & Timeline

When your commercial freezer breaks down, understanding what happens next can ease your stress and help you prepare. Most commercial freezer repair technicians follow a proven process designed to get your unit running again as quickly as possible.

The timeline for repairs varies dramatically depending on what's wrong with your freezer. Simple fixes like replacing a worn door gasket or swapping out a faulty thermostat can often be wrapped up in just a few hours. But if your compressor has failed or you need specialized parts, you might be looking at a multi-day process while components are ordered and shipped.

Same-day repairs are absolutely possible for most common issues, especially when you're working with a repair service that stocks frequently needed parts on their trucks.

Step-by-Step Breakdown

Your repair visit starts with a thorough inspection where the technician examines your freezer inside and out. They're looking for obvious problems like water leaks, damaged door seals, or unusual frost patterns.

Temperature logging comes next, using precision digital thermometers to measure temperatures throughout your freezer. The technician will check multiple spots to see if there are warm areas or if the entire unit is struggling to maintain proper temperature.

Electrical testing involves checking the power supply, testing individual components, and making sure all the wiring connections are solid. Many freezer breakdowns actually stem from electrical issues rather than mechanical problems.

Pressure readings on the refrigeration system tell the story of what's happening inside the sealed refrigerant circuit. These measurements help diagnose compressor problems, refrigerant leaks, and blockages that you can't see from the outside.

After completing these diagnostics, your technician will explain exactly what's wrong and provide a written estimate for the repairs.

Parts Most Often Replaced

Door gaskets top the list of components that need regular replacement in commercial freezers. These rubber seals take a beating from constant opening and closing, plus the extreme temperature changes.

Thermostats are another common replacement item, especially in older freezers with mechanical controls. These devices tell your compressor when to turn on and off, so when they fail, you might end up with a freezer that's too warm or one that runs constantly.

Fan motors for both the evaporator and condenser coils wear out over time. You'll usually hear these failing before they completely quit – grinding noises, squealing, or intermittent operation are all warning signs.

Compressors are the heart of your refrigeration system and also the most expensive component to replace. The good news is they typically last around 10 years with proper maintenance.

Control boards in modern freezers manage everything from defrost cycles to safety shutoffs. While they're more reliable than the old mechanical controls, they can still fail due to power surges or simply aging out after years of service.

| Component | Typical Repair Cost | Replacement Threshold | Decision Factors |

|---|---|---|---|

| Door Gasket | $150-300 | Always repair | Cost-effective, prevents energy waste |

| Thermostat | $200-400 | Repair if under 15 years | Modern units more reliable |

| Fan Motor | $300-600 | Repair if under 12 years | Essential for air circulation |

| Compressor | $1,500-3,000 | Consider replacement if over 10 years | Most expensive component |

| Control Board | $400-800 | Repair if under 8 years | Technology improvements favor newer units |

Costs, Maintenance & Maximizing ROI

When your freezer breaks down, the first question on your mind is probably "How much is this going to cost me?" The answer depends on several key factors that can make the difference between a minor expense and a major budget hit.

Unit size plays a huge role in repair costs. A small under-counter freezer might cost $200-400 to fix, while a large walk-in system could run $1,500 or more for the same type of problem.

Brand matters too. Some manufacturers have parts readily available at competitive prices, while others might require special ordering or proprietary components that cost a premium.

Emergency service is where costs can really add up. Most repair companies charge 50-100% more for after-hours, weekend, or holiday calls. A $300 repair during business hours might cost $600 on a Sunday night.

For help finding reliable service providers who offer fair pricing, check out our guide on how to find reliable refrigeration repair in 5 simple steps.

Repair vs. Replace Decision Matrix

The old "50% rule" is a good starting point: if repair costs exceed 50% of replacement cost and your unit is over 10 years old, replacement usually makes more financial sense.

Age threshold considerations matter a lot. Units under 5 years old are almost always worth repairing unless there's catastrophic damage. Between 5-10 years, you need to look at the maintenance history and overall condition.

For units over 15 years old, replacement often makes sense even for moderate repairs. Efficiency upgrades in newer models can be dramatic. Today's commercial freezers use 20-30% less energy than units from 15 years ago.

Don't forget about business impact either. If your current freezer has become unreliable - breaking down every few months or struggling to maintain temperature - the peace of mind from a new unit might justify the investment.

Preventative Maintenance Schedule

The best commercial freezer repair is the one you never need. A solid maintenance schedule can extend your freezer's lifespan by 30-50% and reduce energy consumption by up to 15%. Given that commercial freezers consume 17,000-35,000 kWh annually, that's real money.

Monthly maintenance should include cleaning those condenser coils with a brush attachment on your vacuum. Dirty coils make your compressor work harder and use more energy. While you're at it, check door seals for cracks or tears, and make sure defrost cycles are working properly.

Quarterly tasks involve more thorough gasket inspections - these seals take a beating and need regular attention. Check door hinges and closers for proper alignment too.

Annual professional tune-ups are worth every penny. A qualified technician will do a complete system inspection, check refrigerant levels, test electrical components, and calibrate temperature controls. This service typically costs $200-400 but can prevent major failures that cost thousands.

Emergency Service, Industry Impact & Downtime Mitigation

When your commercial freezer breaks down, every minute matters. The harsh reality is that businesses can lose thousands of dollars in spoiled inventory within just a few hours of a system failure. That's why 24/7 emergency commercial freezer repair service isn't just convenient—it's absolutely essential for protecting your investment.

The impact of refrigeration failure varies dramatically across different industries. A restaurant might face the frustration of losing a day's worth of food prep, but a pharmaceutical facility could watch tens of thousands of dollars in temperature-sensitive medications become worthless.

At American Mortuary Coolers, we've seen how critical reliable refrigeration is in specialized applications. In our work with funeral homes across the country, we understand that some situations simply cannot tolerate any downtime. That's exactly why we've built partnerships with vetted technicians throughout our service regions, from our Tennessee headquarters to our locations in Atlanta, Chicago, Dallas, Los Angeles, New York, and Pittsburgh.

Many emergency situations stem from defrost problems that could have been prevented with proper maintenance. For detailed technical insights into these common issues, check out this Latest research on defrost problems.

Minimizing Product Loss During Repairs

Smart planning can mean the difference between a minor inconvenience and a major financial loss. Data logging systems are your first line of defense, automatically documenting temperature excursions that might be needed for insurance claims or regulatory compliance.

Backup power solutions range from simple UPS systems that handle short outages to full generator connections for extended repairs. While the upfront investment might seem significant, it's usually justified by preventing just one major product loss.

Don't underestimate the power of proper staff training. Simple door management practices like minimizing how long freezer doors stay open and ensuring nothing blocks airflow can prevent minor issues from snowballing into emergency situations.

Having temporary cold storage arrangements ready before you need them is crucial. Know which nearby facilities can accept your inventory on short notice, or research portable refrigeration rental companies in your area.

Scheduling Commercial Freezer Repair Service Fast

When your freezer goes down, you need help now. Online booking systems have revolutionized emergency service scheduling, allowing you to request help 24/7 and often showing real-time technician availability.

Phone hotlines remain essential for true emergencies when you need immediate human contact. Look for services that have real people answering calls directly rather than routing you through answering services or automated systems.

Local coverage often trumps big-name recognition when you're facing an emergency. While national chains offer consistency, local providers typically have faster response times and better understanding of regional challenges.

For detailed guidance on choosing the right specialist for your specific needs, visit our comprehensive guide on More info about x services.

The best emergency service is the one you never need to use. Regular maintenance and early attention to warning signs can prevent most emergency situations from happening in the first place.

Frequently Asked Questions about Commercial Freezer Repair

How much does commercial freezer repair cost on average?

Commercial freezer repair costs typically range from $200 for simple fixes like thermostat replacement to $3,000+ for major compressor work. The average service call runs $400-800 including labor and common parts.

Several factors affect pricing:

- Unit type and size: Walk-in freezers cost more to service than reach-in units

- Complexity of the issue: Electrical problems often take longer to diagnose than mechanical failures

- Parts availability: Common components like gaskets and thermostats are less expensive than specialized parts

- Emergency service: After-hours and weekend calls typically carry 50-100% surcharges

- Geographic location: Urban areas generally have higher labor rates but better parts availability

Many companies offer flat-rate pricing for common repairs, which eliminates surprises and makes budgeting easier.

How often should a commercial freezer be serviced?

Regular maintenance schedules depend on usage intensity and operating environment, but general guidelines include:

Monthly: Clean condenser coils, check door seals, verify defrost operation

Quarterly: Thorough gasket inspection, door alignment check, accessible evaporator coil cleaning

Annually: Professional tune-up including refrigerant levels, electrical testing, and control calibration

High-use environments like busy restaurants may need more frequent service, while lower-use applications can sometimes extend intervals. The key is consistency - irregular maintenance often costs more in the long run than systematic care.

Semi-annual professional maintenance is recommended for most commercial applications. This typically costs $200-400 but can prevent major failures and extends equipment life by 30-50%.

Are emergency, same-day repairs really possible?

Yes, most commercial freezer repair services can provide same-day response for emergency calls. However, several factors affect feasibility:

Parts availability: Technicians typically stock common components like gaskets, thermostats, and fan motors on their trucks. Specialized parts for older units may require ordering.

Technician availability: Urban areas generally have better coverage, while rural locations might face longer response times.

Complexity of repair: Simple fixes like replacing a door seal can be completed in under an hour, while major component replacement might take most of a day.

Time of service call: Calls received early in the day have the best chance of same-day completion.

Many services guarantee response within 4-6 hours for emergency calls, with repairs completed the same day in 80-90% of cases. For complex repairs requiring special parts, temporary solutions like portable refrigeration might be provided to minimize product loss.

Conclusion

When your commercial freezer repair needs arise, you're not just fixing a machine - you're protecting your entire business operation. Every hour of downtime can mean spoiled inventory, disrupted service, and frustrated customers. That's why understanding commercial refrigeration maintenance isn't just helpful - it's essential for your bottom line.

Throughout this guide, we've walked through the warning signs that signal trouble ahead, from temperature fluctuations that creep up slowly to the sudden silence of a failed compressor. We've explored the repair process itself, helping you understand what to expect when a technician arrives at your door. Most importantly, we've shown you how preventative maintenance can extend your equipment's life by 30-50% while keeping those hefty energy bills in check.

At American Mortuary Coolers, we've seen how critical reliable refrigeration is across industries. While our specialty lies in custom mortuary coolers for funeral homes, the principles of proper cold storage apply whether you're preserving flowers in Atlanta, storing vaccines in Chicago, or keeping food fresh in a busy Dallas restaurant. Our Tennessee-based team has delivered solutions across all 48 contiguous states, and we understand that when refrigeration fails, every minute counts.

The math is compelling: with commercial freezers consuming 17,000-35,000 kWh annually and lasting 10-20 years with proper care, investing in regular maintenance and timely repairs makes perfect financial sense. Professional tune-ups that cost $200-400 can prevent emergency repairs that run into thousands, not to mention the product losses that follow equipment failures.

Remember the key strategies we've covered: schedule regular maintenance before problems arise, address warning signs immediately rather than hoping they'll resolve themselves, and work with qualified technicians who understand the urgency of your situation. When that defrost timer starts acting up or those door gaskets begin to wear, don't wait - early intervention is always less expensive than emergency repairs.

Your refrigeration system works around the clock to protect your business. Shouldn't you return the favor with the care and attention it deserves? Whether you need specialized equipment solutions or reliable service partnerships, we're here to help ensure your cold storage never lets you down.

Ready to take the next step in protecting your refrigeration investment? Find how our durable, custom solutions and nationwide service network can support your business at More info about our custom coolers & service.