A Practical Guide to Reefer Refrigerated Trailer Options

Why Reefer Refrigerated Trailers are Essential for Temperature-Sensitive Cargo

A reefer refrigerated trailer is a specialized insulated trailer equipped with its own refrigeration unit, designed to maintain precise temperatures for transporting perishable goods. These trailers are the backbone of cold-chain logistics, ensuring everything from fresh produce to life-saving vaccines reaches its destination safely.

Quick Overview of Reefer Refrigerated Trailers:

- Temperature Range: -20°F to 70°F (-29°C to 21°C)

- Power Source: Dedicated diesel engine or electric standby

- Fuel Consumption: 0.5-1.5 gallons per hour

- Common Sizes: 36ft to 53ft lengths

- Primary Uses: Food, pharmaceuticals, chemicals, flowers

- Key Features: Multi-zone capability, remote monitoring, precise climate control

The refrigerated transportation industry has grown dramatically as businesses recognize that maintaining the cold chain isn't just about preventing spoilage - it's about regulatory compliance, customer satisfaction, and protecting valuable cargo investments. Modern reefer trailers maintain temperatures as low as -20°F while offering advanced features like real-time monitoring and multi-temperature zones.

Whether you're transporting frozen foods, temperature-sensitive pharmaceuticals, or specialty products requiring precise climate control, understanding your reefer options is crucial for operational success.

As Mortuary Cooler, I've spent years helping businesses steer the complexities of temperature-controlled transportation and storage solutions, including extensive work with reefer refrigerated trailer systems and cold-chain logistics.

Reefer refrigerated trailer further reading:

Understanding Reefer Refrigerated Trailer Fundamentals

Think of a reefer refrigerated trailer as your home refrigerator's industrial cousin - one that maintains perfect temperatures while bouncing down highways at 70 mph. These cooling systems work on familiar principles, just scaled up for serious transportation demands.

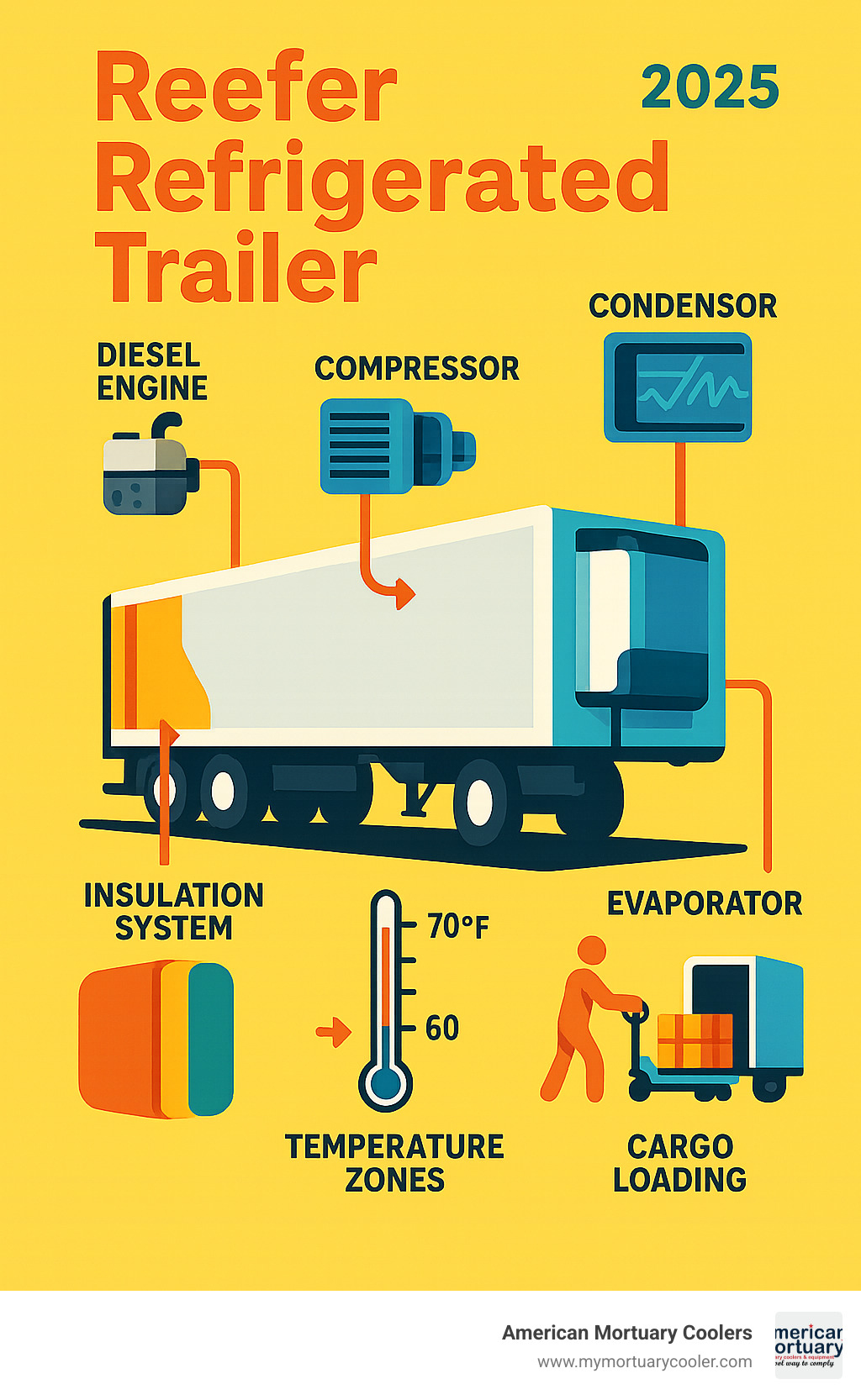

The insulation forms your first line of defense - thick foam-in-place urethane that wraps the entire cargo space like a thermal blanket, engineered to maintain integrity even when the trailer flexes over rough roads.

At the heart of the system, the compressor, condenser, and evaporator work in harmony through the refrigerant cycle. The system maintains temperatures from -20°F to 70°F, providing incredible flexibility for different cargo types. The diesel engine powering the refrigeration unit runs separately from your truck's engine, so cargo stays cool whether you're cruising or stuck in traffic.

What is a reefer refrigerated trailer?

A reefer refrigerated trailer is essentially an insulated van paired with a self-powered refrigeration unit that creates a mobile climate-controlled environment. Unlike regular dry vans, these trailers actively fight temperature changes every mile of the journey.

The insulation system creates walls, floors, and ceilings packed with foam insulation forming a complete thermal envelope with no gaps or weak spots. The refrigeration unit mounts at the trailer's front, looking like a large air conditioning unit but designed for precision temperature control over thousands of miles.

How does a reefer trailer work?

The refrigerant cycle continuously pulls heat from your cargo space. The compressor pressurizes refrigerant gas, heating it significantly. This hot gas flows to condenser coils, where fans blow outside air across coils to cool the refrigerant back into liquid.

The expansion valve allows liquid refrigerant to rapidly expand and cool. This chilled refrigerant flows through evaporator coils inside your trailer, absorbing heat from the cargo area and turning back into gas. The cycle repeats, creating continuous cooling that maintains your set temperature.

Important: reefer trailers excel at maintaining temperature, not rapidly cooling hot loads. Smart operators always pre-cool cargo before loading. Modern units offer cycle operation or continuous operation, with standby electric connections for shore power when parked.

Key components & safety features

Today's reefer refrigerated trailers include advanced safety features. Side-impact guard systems prevent serious underride accidents, proven effective in 35 mph crash tests. Roll stability technology combines ABS braking with sensors that detect potential tip-overs, applying individual brakes to maintain stability.

Temperature monitoring has evolved beyond simple thermostats. Modern sensors track conditions throughout the trailer, while telematics systems provide real-time alerts for temperature drift. These systems maintain compliance records, automatically logging every temperature reading for food safety audits or pharmaceutical regulations.

Diagnostic capabilities display specific alert codes that pinpoint issues, enabling faster repairs and less downtime when moving perishable cargo.

For detailed technical information, check out How it Works – Refrigerated Trailers.

Types, Temperature Ranges & Ideal Cargo

Not all reefer refrigerated trailers are created equal. Different cargo types require different temperature capabilities, and understanding these distinctions helps you choose the right equipment.

The biggest decision is choosing between single-temperature and multi-temperature trailers. Single-temp units maintain one consistent temperature throughout - perfect for full loads of frozen foods or fresh produce. Multi-temp trailers use movable bulkheads to create separate climate zones, letting you carry frozen meat in front and fresh dairy in back during the same trip.

Multi-temp trailers cost more upfront but offer incredible flexibility for maximizing payload by combining different cargo types. The trade-off is slightly higher fuel consumption running multiple climate zones.

Common temperature bands

Reefer refrigerated trailers maintain precise temperatures from bone-chilling cold to pleasantly warm across several key ranges.

Frozen cargo runs from -20°F to 0°F and demands the most from your refrigeration system. Ice cream stays solid at -10°F, while frozen vegetables handle slightly warmer temperatures. These loads require continuous operation since even small temperature swings damage products.

Chilled and fresh goods live in the 32°F to 40°F range for most fresh produce, dairy, and meat products. Fresh lettuce stays crisp at 35°F, and milk maintains quality in this range - the most common temperature zone you'll use.

Controlled ambient temperatures between 50°F and 70°F are essential for products like chocolate (which gets white bloom if too cold), wine (ruined by temperature swings), and pharmaceuticals that lose potency outside ideal ranges.

Some trailers offer heating capability for cargo needing temperatures above 70°F. Certain chemicals solidify at room temperature, and some pharmaceutical compounds require warm storage to remain effective.

Goods that rely on reefers

The variety of temperature-controlled products continues expanding as supply chains become more global. Food and beverage products make up the largest category - from farm-fresh strawberries needing exactly 32°F to premium ice cream that can't survive temperature spikes.

Fresh produce is particularly demanding since different items need different conditions. Apples prefer cool, humid conditions, while bananas suffer damage if stored too cold. Leafy greens need high humidity and consistent temperatures.

Pharmaceuticals represent the fastest-growing segment. Insulin must stay between 36°F and 46°F, while some vaccines require ultra-cold storage. Blood products and diagnostic samples have zero tolerance for temperature deviations.

Specialty products include surprising items like fine art and antiques needing stable temperatures to prevent expansion damage, electronics damaged by extreme temperatures, and cut flowers requiring precise climate control.

Chemicals and hazardous materials often have strict temperature requirements for safety. Some become dangerous when too hot, others solidify and become unusable when too cold. The pharmaceutical sector has become particularly demanding since COVID-19 highlighted cold-chain logistics importance.

Choosing, Buying, Leasing or Renting a Reefer Refrigerated Trailer

When acquiring a reefer refrigerated trailer, you face serious decisions. New units run $60,000 to over $100,000 depending on size and features. Used units start around $25,000 but come with their own considerations. Getting your decision criteria straight saves money and headaches.

Key decision factors

Size matters for your route. Most operators choose between 48-foot and 53-foot trailers, with longer options offering maximum payload capacity up to 20,000 pounds. For tight urban routes or loading dock restrictions, 48-footers work well. For long-haul operations where every cubic foot counts, 53-foot length is hard to beat.

Your cargo mix drives everything else. Hauling only frozen chicken? Single-temperature units keep things simple and cost less. Mixing frozen meat with fresh produce? Multi-temperature trailers with CenterSeal partitions let you run different temperature zones in one trailer, dramatically improving efficiency.

Power options affect daily bottom line. Most reefer refrigerated trailers run on diesel, burning 0.5 to 1.5 gallons per hour. A trailer running 8 hours daily could burn 1,500 to 4,000 gallons annually just for refrigeration. Electric standby capability lets you plug into shore power when parked, cutting fuel costs and emissions.

Technology features are becoming must-haves. Remote temperature monitoring protects cargo and provides compliance documentation. Advanced telematics help with route optimization and predictive maintenance. These features often pay for themselves through reduced spoilage and improved efficiency.

Regulatory compliance can't be an afterthought. FSMA requirements for food transport and GDP standards for pharmaceuticals mean your trailer needs proper temperature logging. CARB regulations in California also affect which units you can operate in certain markets.

Ownership models: buy vs lease vs rent

Buying new gives you everything - latest technology, full warranty coverage (typically 5 years), and complete customization. You pay most upfront, but for high-utilization routes with predictable demand, the math often works favorably.

Used trailers offer middle ground between cost and capability. You save significantly on purchase price, but older units might lack latest monitoring technology or fuel efficiency improvements. Thorough inspection by qualified technicians is non-negotiable, and expect higher ongoing service costs.

Leasing provides flexibility with predictable monthly payments and often includes maintenance packages. It's easier to upgrade to newer technology as your business grows, with potential tax advantages. The downside: you're building equity for someone else, and lease terms can restrict modifications.

Short-term rental works perfectly for seasonal peaks, special projects, or testing waters before purchase commitment. You get maximum flexibility with zero maintenance headaches, though per-mile costs are higher.

Fuel consumption of 0.5 to 1.5 gallons per hour adds up to real money over time. Factor current diesel prices and typical operating hours when calculating total ownership cost.

For detailed lease-versus-buy guidance, check our Ultimate Guide: Refrigerated Truck Lease.

Maintenance, Troubleshooting & Compliance Essentials

Maintaining your reefer refrigerated trailer is critical - when reefers fail, you face repair costs plus thousands in spoiled cargo, unhappy customers, and regulatory headaches. Most problems are preventable with regular attention and solid maintenance routines.

Routine maintenance checklist

The 90-day service interval is your best friend for reefer maintenance. Industry experts recommend professional service every three months, more often during summer when systems work overtime.

Oil changes every 1,500 operating hours keep diesel engines running smoothly. That engine works hard powering your refrigeration compressor in extreme temperatures - clean oil is cheap insurance against expensive repairs.

Daily pre-trip inspections should become second nature. Check belts and hoses for wear, cracks, or loose connections. A $20 belt failure can cost thousands in spoiled cargo. Door seals deserve special attention - worn gaskets let warm air in, forcing systems to work harder and burn more fuel.

Floor channels need clearing of debris for proper airflow. Boxes, pallets, and cargo debris quickly block critical air passages. Good airflow maintains cargo temperature from front to back. Weekly condenser coil cleaning removes dirt, leaves, and road grime that reduce efficiency.

Troubleshooting common problems

Fluid leaks top common reefer problems. Modern technicians use UV leak detection - injecting UV-reactive dye into systems, then using special lights to pinpoint refrigerant escape points. Common leak spots include equalizer tubes, condenser coil connections, and compressor seals.

Air leaks make refrigeration systems work overtime, burning extra fuel and struggling to maintain temperature. Check door gaskets regularly and look for gaps around insulation panels and damaged areas breaking your trailer's thermal envelope.

Sensor calibration issues cause problems when displays show 35°F while cargo sits at 42°F. Use independent thermometers throughout cargo areas to verify system accuracy. Professional calibration ensures spot-on readings for regulatory compliance.

Condenser problems show up as poor cooling performance from blocked airflow, damaged fins, or failed fan motors preventing proper heat exchange. Regular cleaning and inspection prevent most condenser issues.

For detailed troubleshooting steps, see Common Problems With Reefer Trailers & How to Repair Them.

Compliance & food/pharma safety

FSMA regulations require continuous temperature logging for many food shipments. Your reefer refrigerated trailer automatically records this data, but you need to understand accessing and maintaining these records for inspector review.

Pharmaceutical compliance takes temperature control more seriously. Good Distribution Practice (GDP) guidelines demand validated temperature mapping, continuous monitoring, and immediate alerts for temperature excursions. Vaccine hauling requires bulletproof documentation.

CARB compliance matters for California operations. Look for CARB Evergreen certified units meeting strict emissions standards. Remote monitoring systems provide real-time alerts for temperature drift and continuous documentation that regulators and customers increasingly demand.

HACCP principles apply to temperature-controlled transport. Maintain detailed maintenance records, calibrate sensors regularly, and document temperature excursions with corrective actions. Audit records should tell complete cargo journey stories from pickup to delivery.

Future Trends & Innovations in Reefer Trailers

The reefer refrigerated trailer industry is experiencing a revolution driven by environmental regulations, rising fuel costs, and demand for smarter cargo monitoring. Manufacturers are innovating faster than ever.

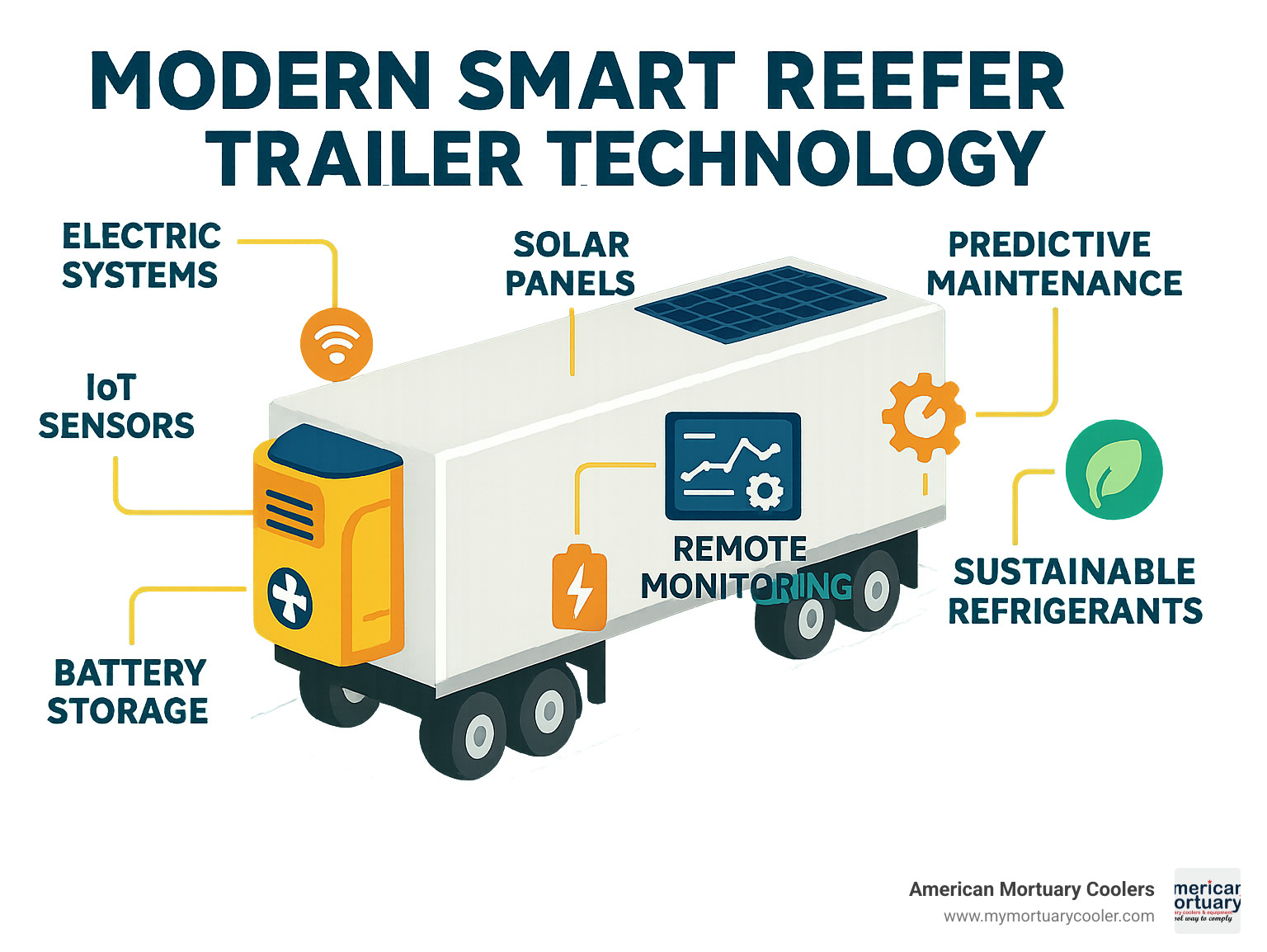

Electric reefers lead the charge toward cleaner futures. These systems replace traditional diesel engines with battery-powered electric motors, offering zero emissions during operation when powered by clean electricity - crucial for urban deliveries with tightening noise and air quality regulations. Quieter operation enables early morning or late evening deliveries without disturbing neighborhoods.

Fleet managers appreciate lower maintenance requirements since electric systems have fewer moving parts. Electric motors provide instant response for precise temperature control without waiting for diesel engines to warm up or throttle down.

Power flexibility is remarkable. Electric reefers run on shore power when parked, switch to battery power during transport, or use hybrid combinations. While upfront investment is higher, operational savings accumulate quickly as electricity costs remain more stable than diesel.

Solar-assisted cooling gains traction with solar panels integrated into trailer rooftops supplementing main refrigeration systems, reducing fuel consumption and extending battery life. While solar panels can't yet power full refrigeration loads alone, they meaningfully reduce overall energy requirements.

The refrigerant revolution happens quietly but importantly. Low-GWP refrigerants (Global Warming Potential) replace older formulations that could harm the environment if leaked. New refrigerants cool as effectively while being environmentally friendlier.

IoT sensors and smart monitoring transform reefer refrigerated trailers into rolling data centers. Modern trailers provide real-time temperature, humidity, and door status monitoring giving dispatchers unprecedented cargo condition visibility. Predictive maintenance alerts warn before component failures, potentially saving thousands in spoiled cargo and emergency repairs.

Route optimization capabilities are clever. Smart systems adjust recommended routes based on cargo requirements, weather conditions, and traffic patterns. For ultra-precise pharmaceutical temperatures, systems can route away from extreme weather or suggest timing changes avoiding temperature stress.

Automated compliance reporting eliminates regulatory documentation headaches. Instead of manual temperature logging, smart reefers automatically generate reports needed for FSMA, GDP, and other regulatory requirements.

Advanced insulation technologies make trailers more efficient. Vacuum insulated panels provide superior thermal performance in thinner profiles, giving better temperature control without sacrificing cargo space. Phase-change materials help stabilize temperatures during door openings or brief power interruptions.

Battery systems become more sophisticated and affordable. Modern lithium-ion battery packs power refrigeration systems for extended periods, and e-axle regenerative braking can recharge batteries while driving.

Sustainability isn't just environmental responsibility - it's business necessity. Companies find that customers, especially large retailers and pharmaceutical companies, require proof of sustainable practices throughout supply chains.

These innovations aren't science fiction - many are available today becoming standard features. Early adopters see benefits in reduced operating costs, improved compliance, and happier customers appreciating environmental responsibility.

For implementation guidance, see A Fleet Manager's Guide to Reefer Trailers.

The future of reefer refrigerated trailers is bright, efficient, and smarter than ever, making cold-chain transportation more reliable, cost-effective, and environmentally responsible.

Frequently Asked Questions about Reefer Refrigerated Trailers

When considering a reefer refrigerated trailer for your business, you likely have questions about real-world performance. Let me address the most common concerns based on years of helping businesses steer temperature-controlled transportation.

How cold can a reefer refrigerated trailer get?

A standard reefer refrigerated trailer reliably maintains temperatures as low as -20°F (-29°C) and as warm as 70°F (21°C). Actual temperatures depend on several real-world factors.

Insulation quality makes huge differences - better insulation means reaching lower temperatures while using less energy. Ambient conditions outside play big roles. When it's 100°F outside and you're maintaining -10°F inside, systems work much harder than on mild days.

Cargo load affects performance too. Loading warm products that haven't been pre-cooled forces systems to work overtime bringing everything to temperature. Most experienced operators pre-cool cargo before loading - it's essential for maintaining consistent temperatures.

Door openings during loading let warm air rush in, so minimizing access time helps maintain setpoints. Most frozen food transport happens between -10°F and 0°F, while fresh produce typically needs 32°F to 40°F.

Reefer units maintain temperatures rather than rapidly cooling hot loads - they maintain cold chains rather than creating them from scratch.

What is the average fuel consumption?

Reefer refrigerated trailers typically burn 0.5 to 1.5 gallons of diesel fuel per hour just for refrigeration - completely separate from truck driving fuel. This consumption really adds up in operating costs.

Temperature differential between inside and outside has the biggest fuel impact. Keeping frozen products cold on hot summer days uses significantly more fuel than maintaining chilled temperatures during mild weather. Poor insulation condition forces systems to work harder, burning more fuel compensating for heat infiltration.

Cargo type matters - frozen loads consistently consume more fuel than chilled products because systems run more continuously. Operating mode affects consumption too. Continuous operation for ultra-sensitive products uses more fuel than cycle mode.

Unit age and condition play roles. Well-maintained reefers operate efficiently, while older units with worn components might burn 20-30% more fuel doing the same job.

A trailer running 10 hours daily could easily consume 5-15 gallons just for refrigeration. Many operators invest in electric standby capability - when parked at docks with shore power, you switch off diesel engines and run on electricity, saving fuel and reducing emissions.

How do you load cargo for proper airflow?

Proper loading makes the difference between successful deliveries and costly cargo claims with your reefer refrigerated trailer. Too many loads arrive damaged because cargo blocked airflow, creating hot spots and temperature variations.

Pallet spacing is crucial - leave 6 inches between pallets and walls and maintain 4-inch gaps between pallet rows. This might seem like wasted space, but proper airflow is more important than cramming in every box. Never block return air bulkheads, and always keep cargo below red load lines marked inside trailers.

Floor channel management gets overlooked but is critical. Never block floor channels with cargo or let debris accumulate - air needs flowing freely under pallets. Use pallets designed for airflow, not solid-deck pallets blocking air circulation.

Pre-cool your cargo to desired temperature before loading. Load heaviest items first and lighter products on top. Don't overfill trailers thinking you're maximizing efficiency - proper airflow beats maximum capacity every time.

For multi-temperature loading with bulkheads, place frozen products in front sections closest to evaporators, with fresh items in rear sections. Ensure bulkheads seal properly - gaps defeat separate temperature zone purposes.

Conclusion

Choosing the right reefer refrigerated trailer can make or break your cold-chain operations. You now have the knowledge to make smart decisions that protect your cargo and business.

Temperature-controlled transport is more complex than moving products from point A to B - you're maintaining precise environments that keep food fresh, pharmaceuticals effective, and specialty items intact. Whether you need -20°F deep freeze for ice cream or precise 35°F control for fresh produce, the right trailer becomes your partner in delivering quality.

Reliability forms the foundation of successful reefer operations. Regular maintenance every 90 days isn't just suggestion - it's insurance against costly breakdowns and spoiled loads. Pre-trip inspections separate professionals from amateurs in this business.

Efficiency drives profitability. Modern trailers with remote monitoring and smart sensors don't just prevent problems - they help optimize routes, reduce fuel consumption, and satisfy demanding customers expecting real-time shipment updates.

Compliance protects your reputation. FSMA regulations and pharmaceutical standards are getting stricter. Continuous temperature logging and documentation requirements that seem burdensome today become your competitive advantage tomorrow.

At American Mortuary Coolers, we've spent years helping businesses steer complex temperature-control challenges. From our Tennessee headquarters, we've seen how effective cooling principles apply across industries - whether preserving dignity in our specialty field or ensuring fresh groceries reach families nationwide.

The reefer refrigerated trailer industry keeps evolving. Electric systems gain ground, sustainable refrigerants become standard, and IoT monitoring changes how we track and protect cargo. These aren't distant possibilities - they're happening now.

Your investment in quality equipment pays dividends through years of reliable service. Whether you buy, lease, or rent, choosing proven technology and maintaining it properly creates foundations for long-term success. The 0.5-1.5 gallons per hour fuel cost becomes manageable when trailers run efficiently and cargo arrives in perfect condition.

For businesses ready for the next step, our Ultimate Guide: Refrigerated Truck Lease provides detailed guidance for making right financial decisions for your specific situation.

The cold chain never breaks when you're prepared. With the right trailer, proper maintenance, and smart operational practices, you'll deliver not just products, but peace of mind.