A Practical Guide to Finding an Affordable Walk-In Cooler

Why Finding an Affordable Walk-In Cooler Is Crucial for Small Businesses

Finding an affordable walk in cooler can mean the difference between growing your business and watching profits disappear through spoilage and inefficiency. Whether you're running a funeral home, restaurant, farm operation, or specialty business, the right cooling solution protects your inventory while keeping costs manageable.

Quick Answer: Most Affordable Walk-In Cooler Options

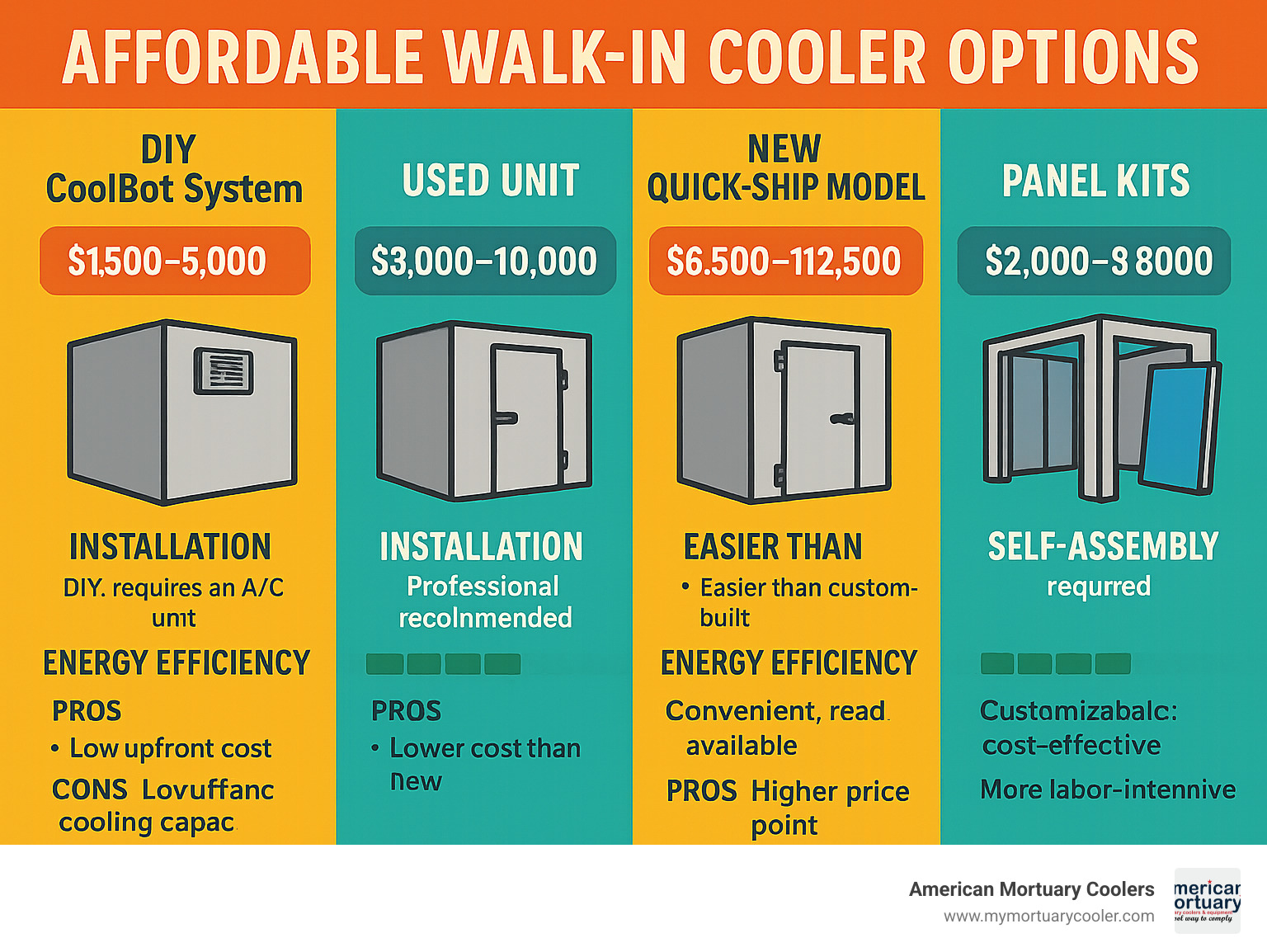

- DIY CoolBot System: $1,500-$5,000 (saves up to 72% vs. commercial units)

- Used/Refurbished Units: $3,000-$10,000 (inspect thoroughly first)

- Quick-Ship New Models: $6,500-$12,500 (8x8 to 8x12 sizes)

- Panel Kits: $2,000-$8,000 (self-assembly required)

The cold storage market has exploded as small businesses find that walk-in coolers aren't just for big operations anymore. Over 125,000 CoolBot units have been sold worldwide, helping businesses save thousands in upfront costs and 40% in operating expenses compared to traditional commercial refrigeration.

A milk collection center in Guatemala saw production jump from 3,000 pounds to 17,000 pounds per week within six months of installing an affordable walk-in cooler system. That's the kind of growth potential we're talking about.

As specialists at American Mortuary Coolers, we've spent years helping funeral directors and specialty businesses find reliable, budget-friendly cooling solutions that fit their unique space and operational needs.

Understanding Walk-In Coolers: How They Work & Why They Matter

Think of a walk-in cooler as a refrigerator you can actually walk into - but the science behind keeping things cold is surprisingly sophisticated. The magic happens through a continuous evaporator-condenser cycle that's been keeping businesses profitable for decades.

The evaporator coil inside your cooler absorbs heat from your stored items, while the condenser coil outside releases that heat into the air. Quality affordable walk in cooler units use 4-inch thick urethane panels with R-values between 25 and 29.

Temperature control is everything. The sweet spot for most applications is 38°F - cold enough to preserve your inventory without risking freeze damage. The FDA sets the maximum at 41°F for food safety.

Industries from restaurants and florists to farms and funeral homes have found that walk-in coolers deliver three major benefits: massive storage capacity, dramatically reduced spoilage, and energy efficiency that beats multiple reach-in units every time. Learn more about Polar King's fiberglass exterior design to see how material choices affect long-term performance.

What Is a Walk-In Cooler?

An affordable walk in cooler is essentially a custom-built refrigerated room designed around your specific needs. Insulated panels form the foundation - walls, ceiling, and sometimes flooring that lock together with cam-lock connections.

The refrigeration system includes your condensing unit (usually outside) and evaporator (inside the cooler). Your thermostat and controls act as the brain, constantly monitoring and adjusting to maintain your target temperature.

Door systems feature heavy-duty gaskets and automatic closing mechanisms. The defrost cycle kicks in automatically when temperatures drop below 35°F, preventing ice buildup that would block airflow and kill efficiency.

Key Business Benefits

Walk-in coolers solve problems that reach-in refrigerators simply can't handle. Bulk storage capacity means you can buy in volume and store efficiently in one space instead of cramming multiple smaller units into your facility.

Reduced spoilage translates directly to profit protection. Consistent temperatures extend product life significantly. Scalable growth becomes possible when you're not limited by the capacity of standard refrigeration.

Typical Sizes & Configurations

Affordable walk in cooler options start with compact 6×6 foot units perfect for small operations and scale up to custom installations over 30 feet long for major facilities.

8×8 foot units (64 square feet) work beautifully for small restaurants, specialty shops, and funeral homes just getting started. 8×10 foot models (80 square feet) handle medium operations comfortably, while 8×12 foot units (96 square feet) serve larger restaurants and distribution needs.

Indoor versus outdoor installation gives you flexibility. Indoor units install inside your existing building, while outdoor units come weatherproofed for external placement. Rail systems add functionality for specific industries like meat processing and funeral applications.

Building or Buying an Affordable Walk-In Cooler: Cost Factors 101

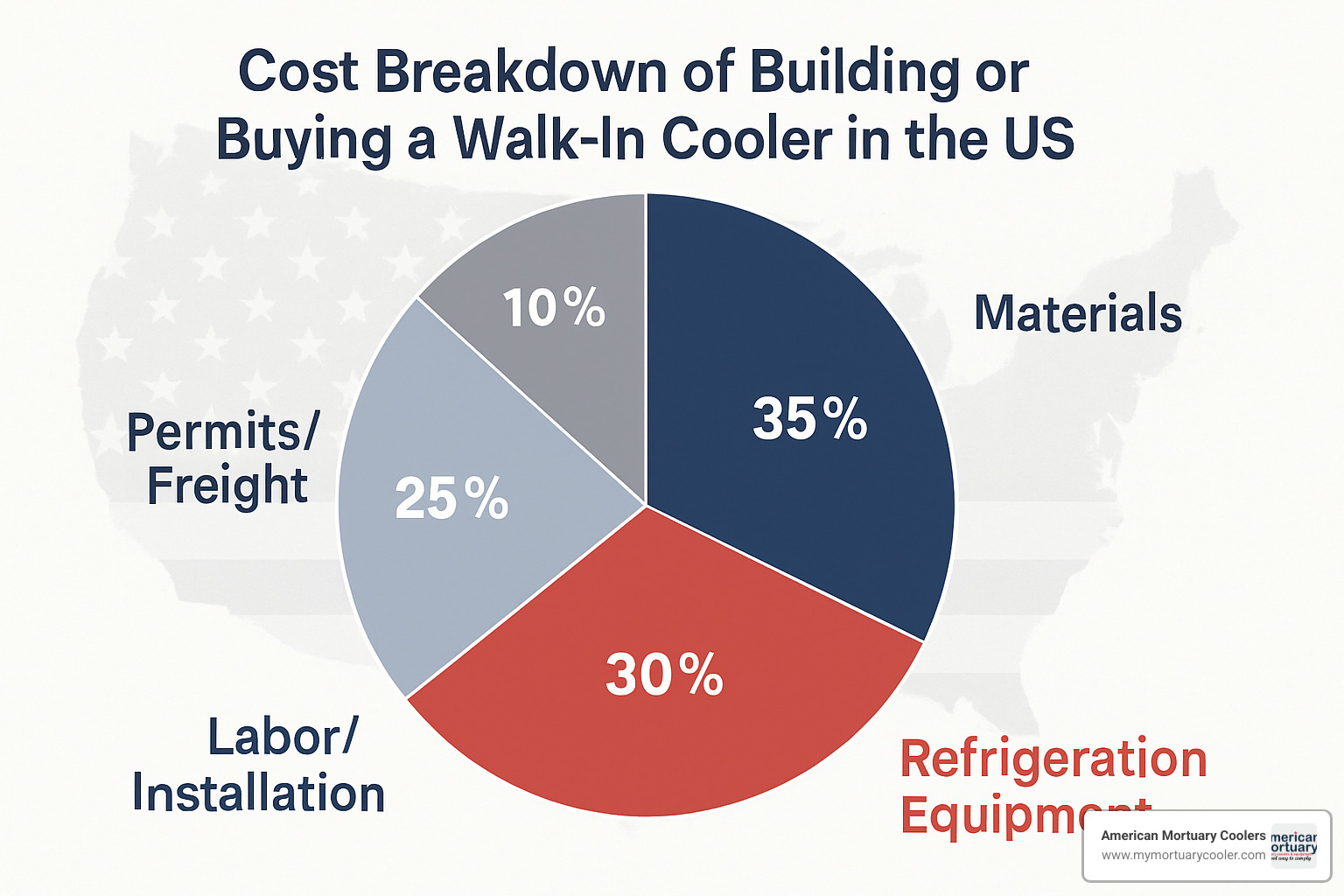

When you're shopping for an affordable walk in cooler, understanding where your money goes helps you make smarter decisions. The biggest chunk of your budget goes to materials, eating up 40-50% of total costs. Refrigeration equipment takes another 25-30%, while labor and installation typically runs 15-20%.

Spending more on insulation upfront often saves you hundreds per year in electricity bills. A 4-inch urethane panel with an R-value of 25 costs more than thinner options, but you'll appreciate the investment every month when the utility bill arrives.

Your refrigeration horsepower needs to match your cooler size perfectly. Too small, and your system works overtime. Too big, and you're paying for power you don't need. Most 8x10 coolers work great with 1-2 HP systems.

Location plays a bigger role than you might expect. Freight charges can add $500-1500 to your project. Some states require engineered drawings for wind or earthquake compliance, tacking on another $500-2000. But utility rebates and tax incentives often offset these extras. Learn more about decoding walk-in cooler pricing factors to understand the full picture.

"Affordable Walk-In Cooler" Price Ranges

New units start around $6,500 for a basic 8x8 model and climb to $8,000 with standard features. Step up to an 8x10 unit, and you're looking at $7,500-$12,500 depending on insulation quality and door options.

8x12 coolers with upgrades typically run $10,000-$15,000, while commercial-grade 10x10 units can reach $12,000-$20,000 with all the bells and whistles.

Used and refurbished units offer serious savings. Small units under 80 square feet go for $3,000-$6,000, while medium-sized units (80-120 sq ft) run $5,000-$8,000. Larger units over 120 square feet typically cost $7,000-$12,000.

The DIY route offers the biggest savings. A CoolBot system with a window air conditioner can get you cooling for just $1,500-$3,000. Panel kits that you assemble yourself run $2,000-$5,000.

Up-Front vs Operating Costs for an Affordable Walk-In Cooler

Your affordable walk in cooler will cost you $50-200 per month in electricity, depending on size, insulation quality, and usage patterns. A well-built 8x10 cooler typically uses 3-5 kWh per day, translating to roughly $30-60 monthly at average utility rates.

CoolBot systems can slash your operating costs by 40% compared to traditional commercial refrigeration. They use efficient residential air conditioners instead of power-hungry commercial units.

Don't forget to check for utility rebates in your area. Many power companies offer $200-1000 rebates for energy-efficient refrigeration equipment.

Financing, Leasing & Used Deals

You don't need to pay cash upfront. Equipment loans typically offer 3-7 year terms at 6-12% APR. Leasing runs $100-300 monthly for mid-size units, while lease-to-own costs more monthly but gives you ownership at the end.

When shopping used units, inspect the panel condition and gasket integrity first. Check the refrigeration system's age and maintenance history because a worn-out compressor can cost thousands to replace. Find walk-in coolers that won't freeze your budget with smart financing strategies.

Comparing the Most Affordable Walk-In Cooler Options

When you're shopping for an affordable walk in cooler, you've got four main paths to choose from. Each has its own sweet spot depending on your budget, timeline, and comfort level with getting your hands dirty.

DIY Panel Kits & CoolBot Controllers

The CoolBot system is like having your cake and eating it too - you get commercial-grade cooling performance using a regular air conditioner that you can buy at any home improvement store.

The magic happens with a small device called the CoolBot Pro controller (around $400) that tricks your air conditioner into thinking it's working in normal conditions while actually maintaining those crucial 38°F temperatures. You build an insulated room using standard construction materials, pop in the controller and a properly sized AC unit, and you're in business.

Your shopping list: insulated panels or framing with foam insulation, the CoolBot Pro controller, a window or mini-split air conditioner (usually 0.5 to 2 tons), vapor barrier and door hardware, plus some basic electrical work.

The savings are real - we're talking up to 72% less than commercial units. One farmer we know built his 8x10 cooler for under $2,500 total. His flowers stay fresh for days longer, and when his AC unit needs service, any local HVAC tech can help him out.

Florists are extending flower life significantly, hunters are processing game like pros, and small farms are practically eliminating post-harvest losses. Check out the CoolBot system for step-by-step build guides.

CoolBot Alternatives under $120

If you're really watching every penny and don't mind electrical tinkering, there's the "Inkbird hack" approach. This uses a basic temperature controller (around $80-120) paired with a small lightbulb to fool your air conditioner's sensor.

The setup involves wrapping the AC's sensor with a 4-watt lightbulb, installing an Inkbird temperature controller, and placing temperature sensors strategically throughout your cooler space.

Unless you're really comfortable with electrical work and can afford some trial and error, the proven CoolBot system is worth the extra investment for peace of mind.

New Quick-Ship & Ready-Ship Models

Sometimes you need cooling now, and that's where quick-ship models shine. These affordable walk in cooler units arrive at your door in 1-4 weeks, ready to assemble.

The 8x8 models run $6,500-$8,000 with shipping included, while 8x10 units bump up to $7,500-$12,500. The larger 8x12 models hit $10,000-$15,000 but give you serious storage space. All come with 4-inch urethane panels, LED lighting, and 5-year compressor warranties.

Two people can typically get these assembled in 4-8 hours with the detailed instructions provided. No specialized tools, no waiting weeks for installation crews.

Used & Refurbished Walk-Ins

The used equipment market is where smart buyers often find their best deals. As the folks at Barr Refrigeration put it after almost 50 years in business: "clever business owners always search for used equipment first."

When inspecting used units, focus on the big-ticket items. Check panels for dents, rust, or damaged insulation. Test door gaskets by making sure they're still flexible and seal completely. Verify the refrigeration system is cooling properly and has recent service records.

Many refurbished units come with limited warranties and have been gone over by certified technicians.

Here's how the options stack up:

| Option | Cost Range | Install Time | Energy Efficiency | Best For | Watch Out For |

|---|---|---|---|---|---|

| DIY CoolBot | $1,500-$5,000 | 2-5 days | Excellent | Budget-conscious DIYers | Need basic electrical skills |

| Used Unit | $3,000-$10,000 | 1-2 days | Good | Quick setup, proven systems | Unknown maintenance history |

| New Quick-Ship | $6,500-$15,000 | 4-8 hours | Excellent | Full warranty, latest efficiency | Higher upfront investment |

| Panel Kit | $2,000-$8,000 | 1-3 days | Very Good | Custom sizing needs | Self-assembly required |

Sizing, Features & Accessories That Stretch Your Dollar

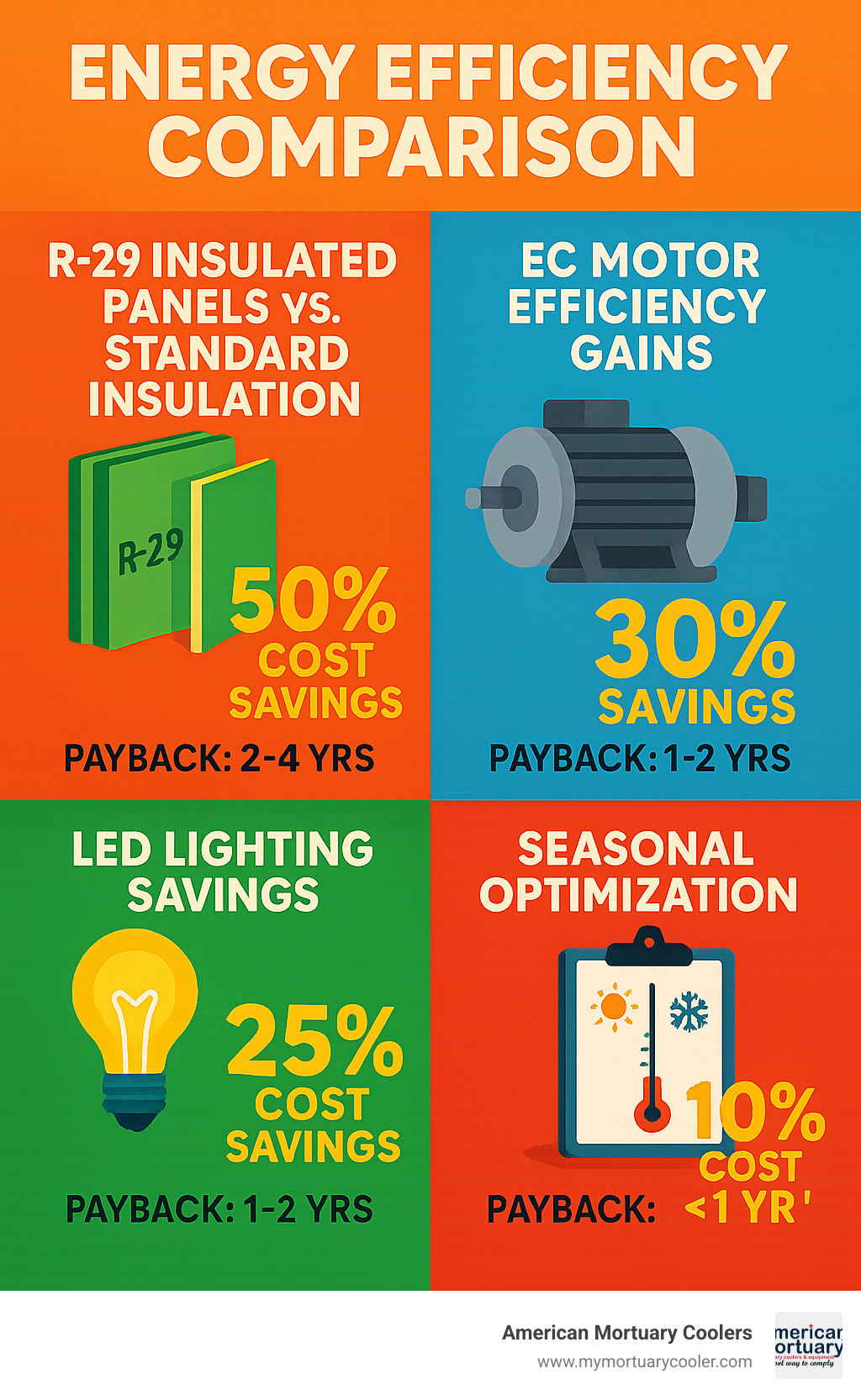

Getting the most value from your affordable walk in cooler means being smart about which features truly matter. The foundation of any good cooler starts with proper insulation. Don't even consider anything less than 4-inch urethane panels with R-25 insulation.

The floor question comes up constantly: should you get an insulated floor or go floorless? If you're installing over existing concrete that's in good shape, floorless units save money and work perfectly fine. But if you're in a humid climate or dealing with an uneven surface, the insulated floor prevents condensation headaches.

Glass doors might seem like a luxury, but they're actually practical money-savers. When staff can see what's inside without opening the door, you reduce temperature loss and energy waste. Pair them with strip curtains for high-traffic situations.

LED lighting is another no-brainer upgrade. LED lights use 75% less energy and last years longer. When you're already investing in an affordable walk in cooler, spending an extra $100-200 on LED lighting pays for itself quickly.

For peace of mind, consider remote monitoring systems like SensorPush. For $50-150, you get instant alerts if temperatures drift out of range. A comprehensive guide to walk-in cooler options covers these features in more detail.

Must-Have Money-Saving Features

EC motors (Electronically Commutated) are worth every penny of the $200-500 premium. These motors use 30-50% less energy than standard motors and run whisper-quiet. The energy savings alone typically pays back the investment within two years.

Auto door closers might seem basic, but they're absolute essentials. Spring-loaded hinges and magnetic gaskets ensure doors seal properly every time.

Fiberglass exteriors offer superior performance compared to metal panels. The thermal conductivity is significantly lower, meaning better temperature control and lower energy bills.

Smart defrost controls eliminate unnecessary defrost cycles that waste energy and cause temperature swings.

Nice-To-Have Upgrades on a Budget

Meat rails transform storage efficiency for funeral homes and specialty applications. At $200-500, they maximize vertical space and keep everything organized.

Keg racks serve breweries and restaurants by keeping products accessible and properly supported.

Temperature alarms provide backup protection for $100-300. Having a loud local alarm ensures someone will know immediately if there's a problem.

Maintenance & Repair Best Practices

Regular maintenance keeps your affordable walk in cooler running efficiently for years. Monthly maintenance should include checking door gaskets for tears or gaps, cleaning condenser coils of dust and debris, verifying temperature accuracy, and inspecting door hinges and closers.

Quarterly tasks involve logging temperature data to spot trends, having refrigerant levels checked by a professional, and cleaning evaporator coils and drain lines.

DIY part sourcing can save you 50-70% on common repairs. Standard components like thermostats, gaskets, and lights are available from multiple suppliers at much lower costs than manufacturer parts.

Operating Costs, Energy Efficiency & Long-Term Savings

The real cost of your affordable walk in cooler isn't just what you pay upfront - it's what you'll spend every month to keep it running. Today's energy-efficient models can dramatically reduce those monthly bills compared to older units or multiple reach-in refrigerators.

Think of insulation as your best friend when it comes to operating costs. R-29 panels might cost more initially than basic R-15 insulation, but they can literally cut your energy consumption in half. That's the difference between a $60 monthly electric bill and a $120 one for the same cooling performance.

Your daily habits matter too. Every time someone opens the door, warm air rushes in and your system works harder. Door usage patterns, ambient temperature around the unit, and how much warm product you add all affect energy consumption.

Modern features like EC fans and LED lighting aren't just nice upgrades - they're money savers that keep working for years. Scientific research on insulation efficiency confirms that proper material selection makes the biggest difference in long-term costs.

Calculating kWh & ROI

A typical 8x10 affordable walk in cooler with quality insulation uses about 3-5 kWh daily. At average electricity rates of $0.12 per kWh, that translates to $30-60 monthly in operating costs.

The simple formula is: Daily kWh = (BTU/hr ÷ 3,412) × Hours of Operation

Modern systems don't run constantly. They cycle on and off based on temperature, typically running 40-60% of the time under normal conditions.

ROI calculations become eye-opening when you factor in spoilage reduction. If your current setup loses $200 monthly to spoiled inventory, and a walk-in cooler costs $100 monthly to operate while eliminating spoilage, you're already ahead by $100 each month. Most businesses see payback periods of 2-4 years through combined energy savings and reduced waste.

Keeping Bills Low Year-Round

Smart operators know that small changes make big differences in energy costs. Night curtains or strip curtains cost just $50-100 but can reduce cooling costs by 10-15% by minimizing air exchange during door openings.

Load management sounds fancy, but it's simple common sense. Adding 500 pounds of warm product all at once forces your system into overdrive. Spread those deliveries throughout the day, and your compressor won't work nearly as hard.

Seasonal adjustments offer surprising savings opportunities. During winter months, you might safely raise your target temperature 2-3 degrees (while staying within safe ranges) and watch your energy consumption drop.

Preventative maintenance isn't just about avoiding breakdowns - it's about efficiency. Clean coils transfer heat better, sealed doors prevent air leaks, and calibrated controls prevent energy-wasting overcooling. A dirty condenser coil can increase energy consumption by 20-30%.

Frequently Asked Questions about Affordable Walk-In Coolers

These are the three questions we hear most often from customers looking for their first affordable walk in cooler. Let's explore each one with real-world answers that'll help you make the right choice.

How much space do I really need?

Here's a simple way to think about sizing: plan for 1-2 cubic feet per $100 of weekly inventory value. So if you're handling $5,000 worth of perishables each week, you'll want somewhere between 50-100 cubic feet of storage space.

But don't just think floor space - vertical storage is your friend. An 8-foot ceiling gives you significantly more usable space than a 7-foot ceiling, especially when you add shelving systems or hanging rails. We've seen funeral directors double their effective storage by thinking vertically.

Remember to account for the practical stuff too. You need room for the door to swing open, space to walk around and access your inventory, and clearance for any equipment maintenance. A cramped cooler becomes frustrating fast, and frustrated staff tend to leave doors open longer - which costs you money.

Can I convert a spare room with a CoolBot and still hit 38°F?

Absolutely - but the devil's in the details. The CoolBot system has proven itself with over 125,000 units sold worldwide, so the technology definitely works. The question is whether your room setup will let it succeed.

Your converted room needs proper insulation first and foremost. We're talking minimum R-13 in the walls, R-19 in the ceiling, and a complete vapor barrier. Any gaps or cracks need sealing - cold air finds every weakness.

Air conditioning sizing matters hugely. Plan on about 1 ton of cooling capacity for every 600-800 cubic feet of space. Too small and you'll never reach target temperature. Too big and you'll get temperature swings that could damage sensitive items.

The door needs weather stripping or proper gaskets. A regular interior door just won't cut it for maintaining 38°F consistently.

When done right, the CoolBot Pro maintains target temperatures reliably. We've seen florists, small funeral homes, and specialty food businesses succeed with conversions. Just don't try to save money on the insulation - it's the foundation everything else builds on.

What's the lifespan of a used walk-in cooler?

A well-maintained affordable walk in cooler can serve you faithfully for 15-25 years or even longer. We've seen units from the 1990s still running strong because someone took care of them properly.

Panel condition tells the story. Quality urethane panels are nearly indestructible if they're protected from physical damage and moisture intrusion. Look for intact surfaces without dents, rust spots, or signs of insulation degradation.

The refrigeration system is usually the limiting factor. Compressors typically last 10-15 years with regular maintenance, though we've seen some push 20 years in light-duty applications. The key is maintenance history - a unit that's been serviced regularly will outlast one that's been ignored, even if it's newer.

Usage patterns make a huge difference. A cooler that's opened constantly in a busy restaurant ages faster than one used for overnight storage in a funeral home. Gentler use extends everything's lifespan.

When shopping used, focus on units under 10 years old with maintenance records if possible. But don't automatically dismiss older units - sometimes you'll find 15-year-old panels paired with a recently rebuilt refrigeration system, which can be an excellent value.

The bottom line? A used walk-in cooler from a reputable source can give you decades of reliable service at a fraction of new equipment cost.

Conclusion

Your journey to finding the perfect affordable walk in cooler doesn't have to be overwhelming. We've walked through everything from DIY CoolBot systems that can save you thousands to reliable used units that get you up and running fast. The beauty is that there's genuinely a solution for every budget and situation.

The numbers speak for themselves - CoolBot systems deliver up to 72% savings upfront while cutting your monthly energy bills by 40%. Used units offer that sweet spot of proven reliability without the new-equipment price tag. And if you want that peace of mind that comes with full warranty coverage, today's quick-ship models deliver quality without the wait.

Here's what really matters: proper sizing beats fancy features every time. A well-insulated 8x10 cooler with basic controls will outperform an undersized unit loaded with bells and whistles. Energy-efficient components like EC motors and LED lighting might cost a bit more upfront, but they're the gift that keeps on giving through lower operating costs.

At American Mortuary Coolers, we've seen how the right cooling solution transforms businesses. From Tennessee funeral homes to California florists, our custom solutions and direct delivery across all 48 contiguous states help businesses find that perfect balance between affordability and rock-solid performance.

Whether you're keeping flowers fresh, protecting food inventory, or maintaining sensitive materials at just the right temperature, an affordable walk in cooler can be the game-changer your business needs. The key is starting with an honest assessment of your space and cooling requirements, then exploring options that actually fit your real-world situation.

Ready to take the next step? Check out our practical guide to walk-in cooler options for detailed specifications and expert guidance custom specifically to your industry needs. Your perfect cooling solution is waiting.