A Practical Guide to Choosing the Right Morgue Fridge

Why Understanding Morgue-Fridge Options is Critical for Your Facility

A morgue-fridge is a specialized refrigeration unit designed to preserve human remains at controlled temperatures, typically between 2°C and 4°C (35.6°F to 39.2°F), to slow decomposition and maintain body integrity for identification, autopsy, or funeral preparation.

Key Morgue-Fridge Facts:

- Temperature Range: 2-4°C for standard storage, -10°C to -50°C for forensic freezing

- Storage Duration: Several hours to weeks depending on temperature control

- Capacity Options: 2 to 50+ bodies across various configurations

- Main Types: Body box units, walk-in coolers, mobile units, bariatric storage

- Construction: Stainless steel 304 grade with high-density polyurethane insulation

- Power: Standard 110V or 208-230V with digital temperature controllers

The science is straightforward: human remains require constant refrigeration to prevent decomposition. Without proper temperature control, bacterial growth accelerates rapidly, making identification and examination difficult or impossible.

Modern morgue-fridge systems feature independent refrigeration systems per chamber, vapor-proof LED lighting, magnetic door gaskets, and digital alarms. Some units offer modular construction for easy relocation, while others include bariatric capabilities for oversized remains.

Whether you're managing a small funeral home or a large hospital morgue, choosing the right system impacts everything from operational efficiency to regulatory compliance. The wrong choice can mean inadequate capacity during peak periods, excessive energy costs, or equipment failures that compromise your facility's mission.

As Mortuary Cooler, a national-level morgue-fridge supplier with experience in mortuary refrigeration systems, I've helped facilities across the country select equipment that matches their specific needs and space constraints.

Easy morgue-fridge glossary:

Morgue-Fridge Fundamentals: Purpose, Temperatures & Storage Limits

A morgue-fridge has one critical job: keeping human remains at the right temperature to slow decomposition while preserving dignity and allowing proper identification, autopsy procedures, and funeral preparation.

The optimal temperature is 2°C to 4°C (35.6°F to 39.2°F). This range slows decomposition without freezing tissues. At these temperatures, bodies can be stored safely for several weeks, depending on humidity controls and system stability.

For forensic work, forensic freezers run much colder at -10°C to -50°C. These units preserve evidence for months or years when cases require long-term storage.

A morgue-fridge isn't just an oversized household refrigerator. These units handle 150 kg (330 lbs) per tray with specialized trolley systems, reinforced construction, and materials that withstand harsh disinfectants.

How a Morgue-Fridge Slows Decomposition

When you drop body temperature to 2-4°C, you're hitting pause on biological processes.

Enzyme inhibition is your first defense. Enzymes that break down cellular structures slow dramatically in cold temperatures, working at a fraction of their normal speed.

Bacterial growth control is equally important. Bacteria responsible for decomposition multiply rapidly at body temperature but slow by up to 90% when chilled.

Humidity balance completes the preservation equation. Modern morgue-fridge units manage moisture levels to prevent tissue dehydration while avoiding bacterial breeding conditions.

Types & Configurations: From Body Boxes to Walk-Ins

Body box units are the industry workhorses, featuring individual chambers with separate doors and temperature controls. Available in 2-body through 15-body configurations, their modular panel construction provides redundancy—if one chamber fails, others keep running.

Walk-in coolers handle serious capacity needs, storing 8 to 50+ bodies using rack tier systems. These units offer flexibility for reconfiguring interior layouts and easier cleaning than multiple smaller units.

Multi-body cabinets bridge the gap between body boxes and walk-ins, typically holding 6-15 bodies in compact footprints perfect for mid-sized facilities.

Bariatric roll-in units address growing needs with reinforced construction and wider doors for oversized remains.

Portable and mobile units provide flexibility for temporary storage, disaster response, or transportation between locations.

The choice between positive temperature systems (2-4°C) and negative temperature systems (-10°C to -50°C) depends on your application—standard storage versus forensic preservation.

Morgue-Fridge Options for Every Facility Size

Community hospitals typically need 4-8 body capacity systems. A 4-body upright morgue-fridge with independent compressors provides reliability without excessive space requirements.

Forensic laboratories require negative temperature capabilities down to -50°C, precise temperature logging, and flexible storage configurations for evidence preservation.

Funeral homes often choose 2-4 body systems, with aesthetics important since families may see the equipment. Many also invest in mobile units for off-site services.

Disaster response operations need rugged, self-contained mobile units that deploy quickly and operate on generator power.

Key sizing questions: What's your typical versus peak capacity? Do you need surge planning? What's your available space? Do you need bariatric capabilities? What's your backup plan if the primary system fails?

Key Features & Innovations That Matter

Stainless steel 304 grade construction resists harsh cleaning chemicals without corroding. Seamless construction eliminates bacteria hiding spots, making sanitation effective.

High-density polyurethane foam insulation maintains stable temperatures even with frequent door openings, keeping energy costs reasonable while ensuring consistent preservation.

Vapor-proof LED lighting provides clear visibility while eliminating moisture damage risks. Exterior switch controls meet OSHA safety requirements.

Independent compressor systems offer redundancy—if one system fails, others continue running. You can also shut down unused chambers during slow periods, saving energy.

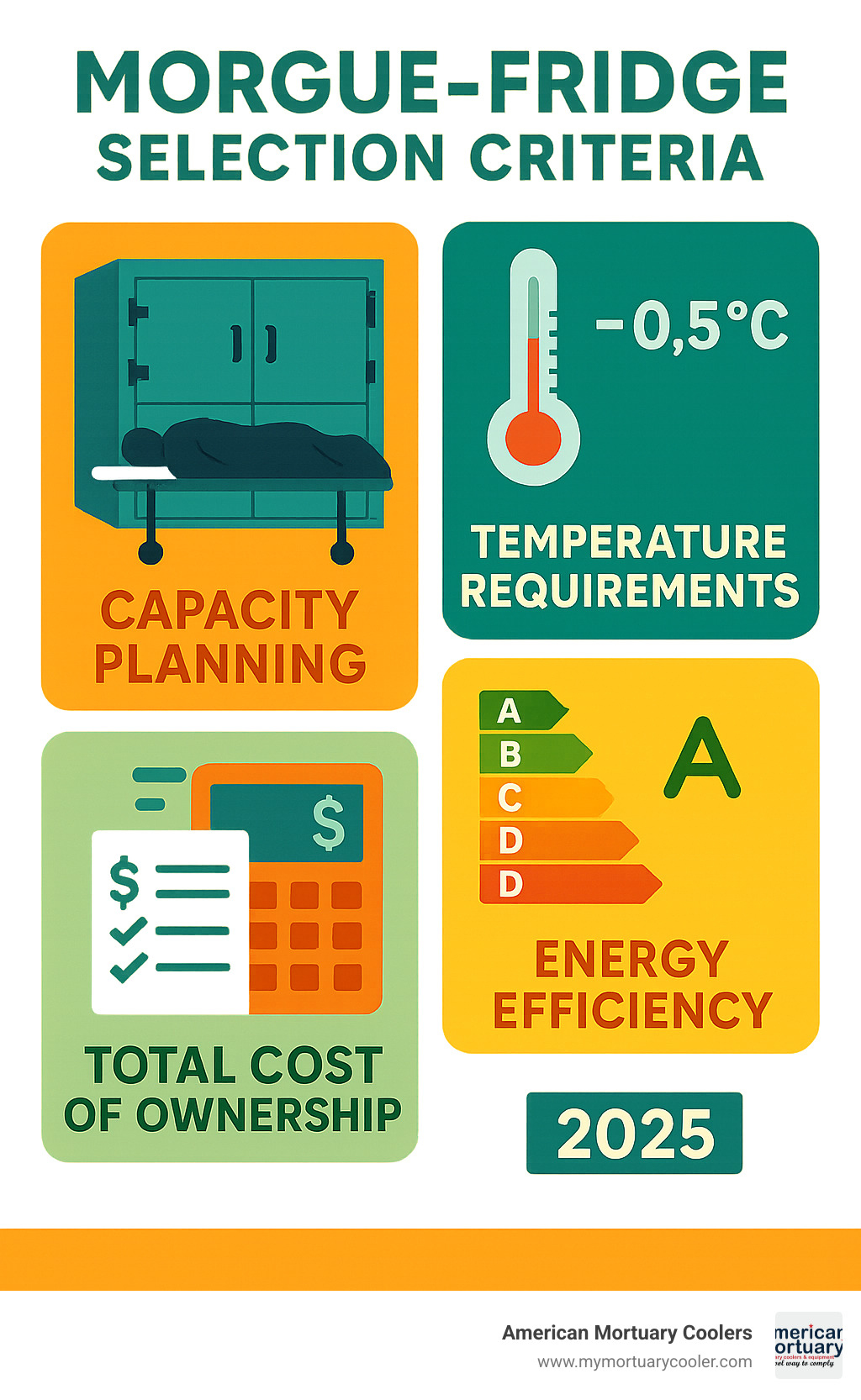

Digital temperature controllers maintain temperatures within ±0.5°C while providing instant alerts and automatic compliance record keeping.

Energy-efficient R-134a refrigerants cool effectively while meeting environmental standards and reducing your facility's carbon footprint.

Advanced features include IoT connectivity for smartphone alerts, cloud-based temperature logs, and predictive maintenance. Antimicrobial finishes provide extra protection beyond regular cleaning.

Tech Checklist When Evaluating a Morgue-Fridge

Temperature precision should be ±0.5°C or better with rapid recovery after door openings and uniform temperatures throughout storage space.

Safety compliance requires OSHA-compliant safety release handles, NSF-approved components, proper UL/CSA electrical certification, and EISA 2007 compliance for energy efficiency.

Construction quality shows in magnetic door gaskets, heated door frames preventing condensation, and substantial stainless steel 304 interior and exterior.

Operational features include clear digital temperature displays, effective audio and visual alarm systems, and vapor-proof lighting with exterior controls.

Advanced options like remote monitoring, data logging, individual chamber controls, and eco-friendly refrigerants can justify costs through improved efficiency and reduced maintenance.

Selecting the Right Morgue-Fridge for Your Facility

Capacity forecasting requires looking beyond typical daily loads. Track patterns for a full year, noting seasonal variations and unexpected surges. Plan for emergency surge capacity—disasters can suddenly double or triple your normal load.

Workflow ergonomics matter for daily operations. Consider how staff will actually use the equipment—rolling gurneys directly into chambers or transferring to trays. The best morgue-fridge is one your team can operate safely and efficiently.

Budget and total cost of ownership extend beyond initial price. Energy-efficient systems cost more upfront but save thousands in electricity over their 15-20 year lifespan. Factor in installation space requirements—some facilities need floor reinforcement, electrical upgrades, or ventilation modifications.

Local regulations vary dramatically. Some jurisdictions require backup power systems, specific alarm configurations, or particular temperature monitoring. Check with your local health department early—it's cheaper to include required features from the start.

At American Mortuary Coolers, we provide custom solutions custom to each facility's unique needs. Our Tennessee-based manufacturing delivers systems across the contiguous 48 states.

For detailed information, visit more info about morgue fridge options and more info about price comparisons.

Step-by-Step Buying Roadmap

Needs assessment takes about two weeks. Document current usage patterns, identify peak periods, and assess space constraints.

Market research involves requesting quotes from at least three suppliers. Compare specifications, warranties, and service offerings—not just prices.

Site preparation often takes longer than expected. Start electrical work, floor reinforcement, and ventilation modifications early.

Delivery and training brings everything together. Be present during installation and invest time in thorough staff training.

Key milestones include securing your purchase agreement, completing site preparation, achieving successful installation, finishing staff training, and activating warranty registration.

The process typically takes 10-12 weeks from start to finish.

Maintenance, Safety & Compliance Essentials

Proper morgue-fridge maintenance protects your facility's reputation and ensures reliability when families need you most. The difference between 20-year versus 10-year system life often comes down to simple maintenance habits.

Clean-in-place protocols require specific cleaning agents that won't corrode stainless steel or leave bacterial residues. Use approved disinfectants and follow manufacturer guidelines religiously.

Weekly temperature logging keeps regulators happy and catches problems early. Modern systems with digital data logging make this easier, but maintain manual backup records for inspectors.

Door gasket inspection prevents energy waste and temperature fluctuations. Check monthly for tears, warping, or weak magnetic seals. Replacing a $50 gasket beats explaining preservation failures to families.

Condenser coil cleaning keeps systems efficient and prevents compressor failures. Clean quarterly, or more often in dusty areas. Dirty coils can double electricity bills.

Annual refrigerant checks by qualified technicians ensure peak efficiency and environmental compliance. Leaks reduce cooling capacity and can trigger EPA violations.

Backup power planning separates professional facilities from amateur operations. Uninterruptible power supplies handle brief outages while generators protect against extended failures.

Quality systems carry CSA, UL, and CE marks proving compliance with safety standards. These certifications are often required by health codes and insurance policies.

Biosafety protocols protect staff during maintenance. Anyone working on morgue-fridge systems needs proper PPE and bloodborne pathogen training.

Building a Preventive-Maintenance Schedule

Daily tasks take minutes but catch problems early: check temperature displays, listen for unusual sounds, ensure doors close properly.

Weekly maintenance focuses on cleanliness: download temperature logs, clean interior surfaces, inspect gaskets, test alarms.

Monthly deep cleaning includes thorough surface cleaning, condenser coil inspection, refrigerant level checks, and drainage verification.

Quarterly professional inspections catch problems users might miss through certified technician tune-ups and calibration.

Annual comprehensive service ensures long-term reliability with complete system inspection, leak testing, and electrical safety testing.

Service contracts provide peace of mind and often cost less than emergency repairs. Look for contracts including regular inspections, priority service, and discounted parts.

At American Mortuary Coolers, we help customers develop maintenance schedules fitting their specific operations and staff capabilities.

Frequently Asked Questions about Morgue-Fridges

How long can a body stay in a morgue fridge?

Bodies can typically stay in a morgue-fridge for several weeks with proper conditions. Temperature stability at 2-4°C makes the biggest difference. Humidity control prevents tissue dehydration while avoiding bacterial growth. Individual factors like health conditions and medications affect storage time. Your facility's protocols may set stricter limits than technical capabilities.

What certifications should a morgue fridge have?

NSF certification ensures components meet medical equipment standards for sanitation and safety. UL certification covers electrical safety and performance. OSHA-compliant safety handles are essential for walk-in systems, preventing entrapment. EISA 2007 compliance ensures energy efficiency, reducing operating costs.

How do morgue fridges differ from standard freezers?

Temperature precision in morgue-fridges holds within ±0.5°C versus several degrees in commercial units. Load capacity handles 150 kg+ per tray with robust construction standard equipment can't match. Hygiene design features seamless stainless steel and medical-grade materials. Safety features like vapor-proof lighting and specialized alarms are built-in. Regulatory compliance requirements are much stricter for morgue equipment than standard refrigeration.

Conclusion

Choosing the right morgue-fridge means investing in your facility's ability to serve families with dignity for years to come. Quality systems run reliably for 15-20 years, making total cost of ownership more important than upfront investment.

At American Mortuary Coolers, we craft custom units in Tennessee with direct delivery across all 48 contiguous states. Our reputation is built on understanding that every facility has unique needs.

Your path forward includes accurately assessing capacity needs, evaluating space constraints, and comparing total ownership costs rather than just prices. Verify proper certifications and solid manufacturer support.

Next steps: reach out to qualified suppliers for quotes, visit similar facilities to see systems in operation, and develop comprehensive plans including staff training and maintenance protocols.

This equipment works quietly during families' most difficult moments. Your morgue-fridge must perform flawlessly during busy periods, unexpected surges, and emergencies when failure isn't an option.

The right system will serve your community reliably for decades. Base your decision on specific needs, not just the lowest bid. Your staff, families, and facility operations will benefit from this reliability every day.

For detailed information about available systems and configurations, check out More info about morgue refrigeration equipment options.