A Comprehensive Guide to Upright Mortuary Coolers

Why Upright Mortuary Coolers Are Essential for Modern Funeral Facilities

An upright-mortuary-cooler is a vertical, self-contained refrigeration unit designed specifically for the dignified storage and preservation of human remains in funeral homes, hospitals, and morgues. These compact units offer a space-efficient alternative to walk-in coolers while maintaining precise temperature control between 36°F and 39°F.

Key Features of Upright Mortuary Coolers:

- Capacity: Store 2-12 bodies depending on model size

- Power: Standard 110V plug - no special electrical work required

- Installation: Self-contained design with no drainage needed

- Dimensions: Typical 2-body unit: 7'3" x 3'¾" x 5'2" (W x L x H)

- Warranty: 15-year panels/doors, 5-year mechanical parts

- Price Range: $6,905 - $24,799 depending on capacity

The beauty of upright mortuary coolers lies in their plug-and-play simplicity. Unlike complex walk-in installations, these units arrive ready to operate within an hour of delivery. They're particularly valuable for rural county morgues, small hospitals, and funeral homes with limited space or infrastructure.

As one funeral director noted: "The quality combined with price is better than I have seen." This sentiment reflects why upright models have become increasingly popular - they deliver professional-grade refrigeration without the complexity or cost of custom installations.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral facilities select the right upright-mortuary-cooler for their specific needs. Through my work with funeral homes across the country, I've seen how the right cooling solution can streamline operations and improve service quality.

Simple upright-mortuary-cooler glossary:

Understanding the Upright Mortuary Cooler

When you're looking at an upright-mortuary-cooler, you're essentially looking at a tall, vertical cabinet that works like a specialized refrigerator. The genius of this design is how it maximizes your storage capacity while taking up minimal floor space - something every funeral director can appreciate.

These units are completely self-contained, which means everything you need is built right in. The refrigeration system sits on top with a compressor that keeps everything running smoothly. No need for external cooling equipment or calling in specialized technicians for complex installations.

Loading options come down to two main choices: side-load and end-load configurations. Side-load units have doors that open from the front, making them perfect when you have good access from the front of the unit. End-load models have doors on the narrow end, which works great in tighter spaces.

The capacity range is impressive. You can start small with a 2-body unit that's perfect for smaller funeral homes, or go all the way up to a 12-body model that can handle the busiest hospitals or regional morgues. The 2-body, 3-body, 4-body, and 12-body configurations are the most popular.

What really sets these units apart is the insulation system. We're talking about R-32 rated, 4-inch thick closed-cell polystyrene panels that keep temperatures rock-steady. These panels meet Department of Energy efficiency standards, which helps keep your operating costs down.

The digital controls take the guesswork out of temperature management with adjustable thermostats and continuous monitoring displays.

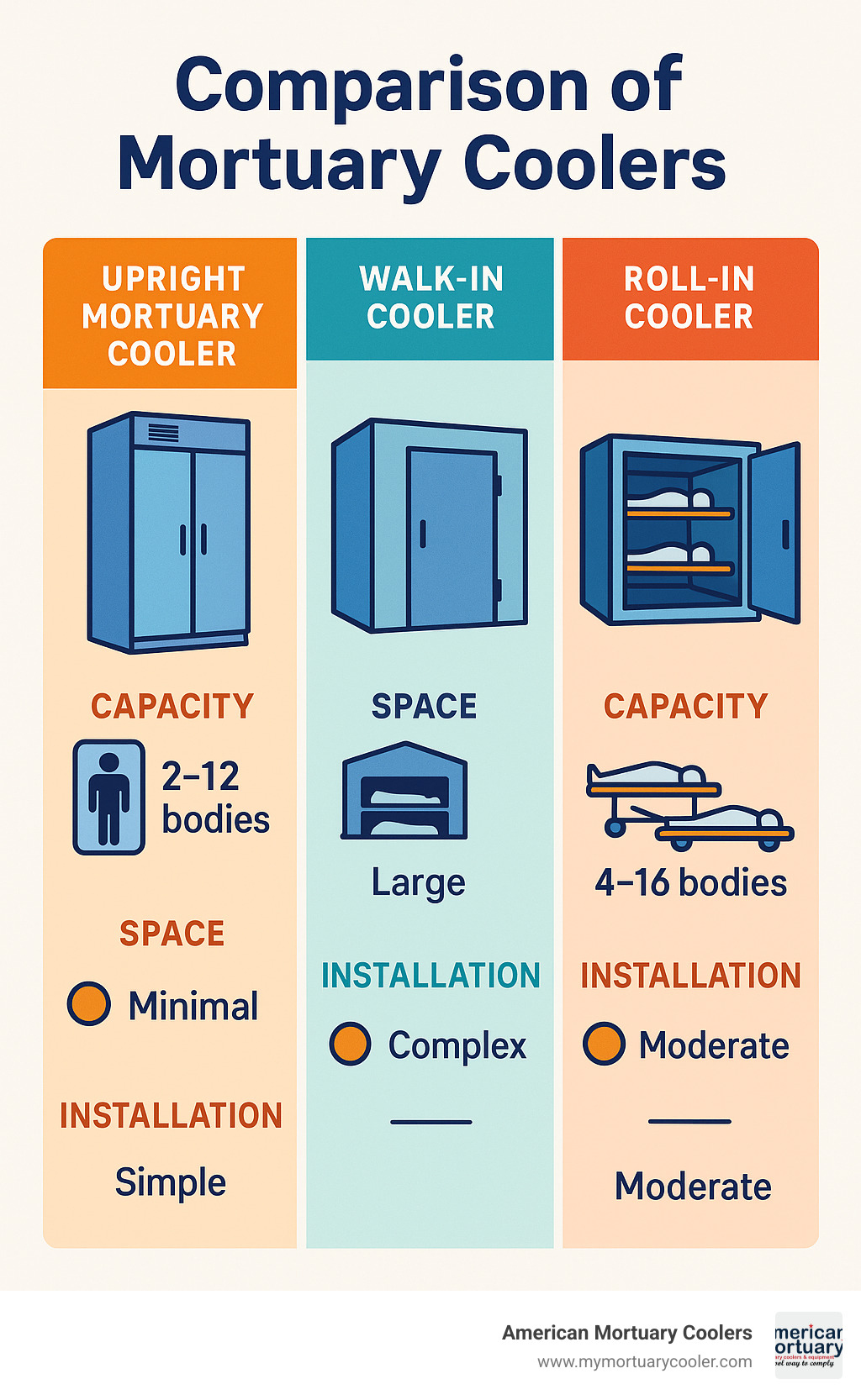

Upright Mortuary Cooler vs Walk-In Units

The biggest advantage of choosing an upright-mortuary-cooler over a walk-in unit comes down to space. While walk-in coolers typically demand at least 8' x 8' of floor space plus clearance, an upright unit can tuck neatly into a corner of your existing prep room.

Installation is where the difference really becomes clear. Walk-in coolers are a project - they need assembled panels, floor installation, and often require custom electrical work that can take days to complete. With an upright unit, you're looking at something that arrives either fully assembled or as a quick-assembly system.

| Unit Type | Bodies | Floor Space | Install Time | Special Requirements |

|---|---|---|---|---|

| 2-Body Upright | 2 | 3'¾" x 7'3" | <1 hour | 110V outlet only |

| 3-Body Upright | 3 | 3'1" x 7'6" | <1 hour | 110V outlet only |

| Walk-In Small | 9+ | 8' x 8' min | 4-8 hours | Electrical, possible plumbing |

| Walk-In Large | 20+ | 10' x 12' min | 8-16 hours | Electrical, plumbing, permits |

Upright Mortuary Cooler vs Roll-In (Cot) Coolers

The main difference between upright and roll-in mortuary coolers comes down to how you handle bodies in your facility.

Roll-in coolers are designed for cot compatibility - you can wheel a mortuary cot directly into the unit without transferring the body. Upright coolers require transferring remains onto internal shelving or roller racks. While this means an extra step in your process, it gives you much better space utilization.

Roll-in coolers usually max out at 2-3 bodies and need extra floor space to accommodate cot clearance requirements. If you're working with limited space but need higher capacity, an upright unit often makes more sense.

Capacities, Sizes & Custom Options

Finding the right size upright-mortuary-cooler for your facility depends on your typical volume and available space. Through years of working with funeral homes across the country, we've learned that most facilities fall into predictable patterns based on their size and service area.

Small funeral homes handling 50-100 cases annually typically find 2-body units perfect for their needs. These compact coolers measure 7'3" x 3'¾" x 5'2" and fit easily into prep rooms. Rural county morgues often prefer 3-body units at 7'6" x 3'1" x 5'2" - just enough extra capacity for unexpected situations.

Mid-size facilities usually gravitate toward 4-body units measuring 7'8.5" x 3'8" x 7'5.5". These provide the sweet spot between capacity and footprint for funeral homes serving larger communities. For high-volume operations like busy hospitals or regional morgues, 12-body units offer custom dimensions custom to specific space requirements.

Door widths typically range from 30 to 31.5 inches - wide enough for standard mortuary equipment while maintaining energy efficiency. Custom finishes help your cooler blend seamlessly with your facility's appearance. Stucco embossed aluminum offers durability and easy maintenance, while galvanized steel provides cost-effective protection. For premium installations, stainless steel delivers that polished, professional look.

Extra-wide models accommodate larger individuals or specialized equipment. We can also customize the number of doors, internal configurations, and even add viewing ports for quick inspections without opening the main compartment.

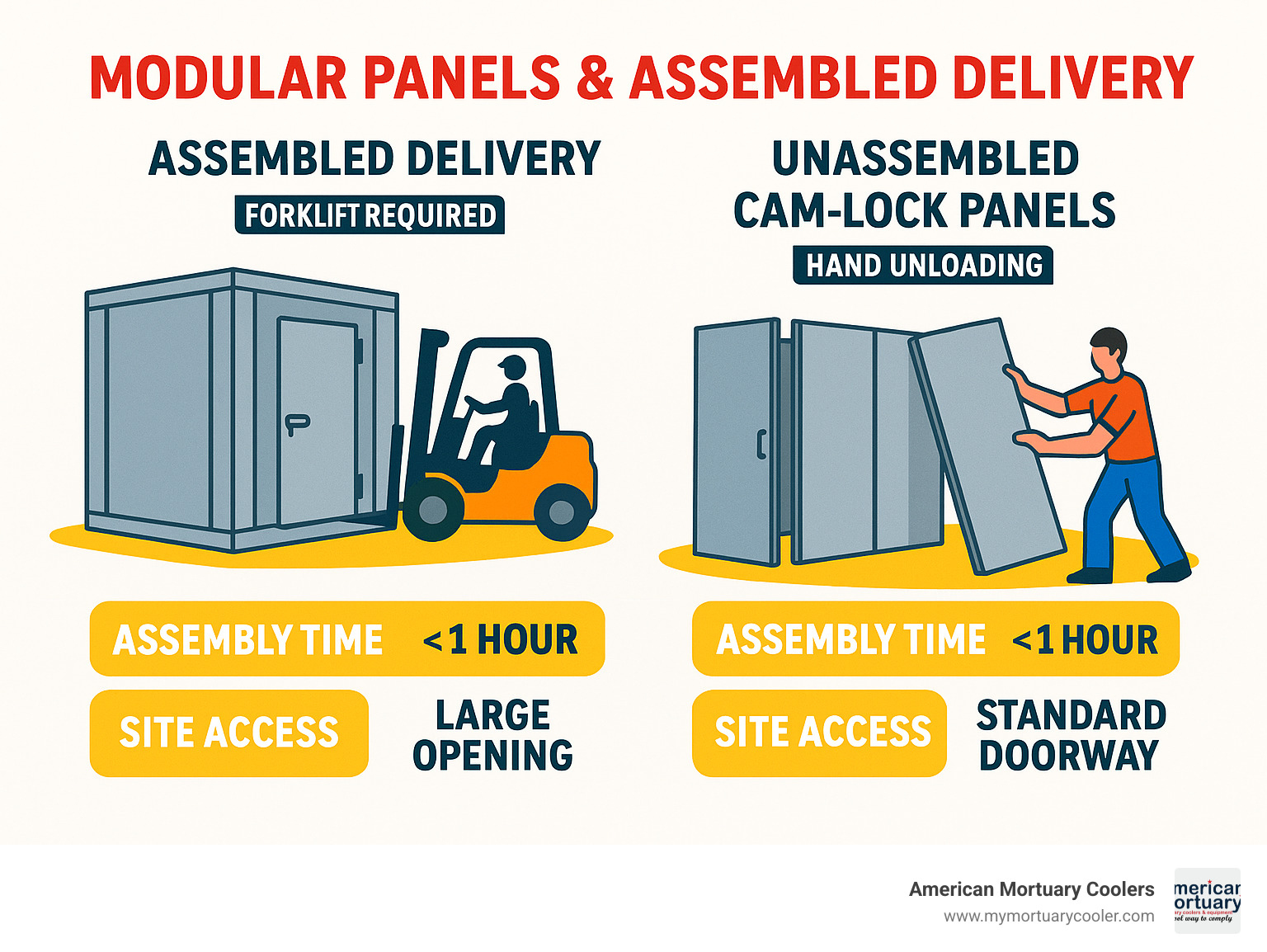

Modular Panels & Assembled Delivery

One of the smartest innovations in mortuary cooling is the cam-lock panel system. These panels connect using specialized hardware that creates perfectly secure, insulated joints without requiring professional installation. We can ship your cooler unassembled, dramatically reducing freight costs and eliminating the need for forklift access.

Assembled delivery offers convenience - your cooler arrives ready to plug in. However, this option requires forklift access and adequate site clearance. The higher shipping costs and potential access limitations make assembled delivery less practical for many facilities.

Unassembled units can be hand-unloaded from delivery trucks, making them accessible to virtually any location. While some carriers charge additional fees for hand-unloading, the total cost usually remains lower than assembled delivery.

Assembly typically takes under one hour using basic tools: a cam-lock wrench (which we provide), power drill, level, tape measure, and rubber mallet. The process is straightforward enough that most facility staff can handle it without outside help.

Customizable Features

Casters transform your stationary cooler into a mobile unit - incredibly valuable for facilities requiring flexible layouts or emergency response capabilities. Roller rack systems maximize your storage efficiency with 3-tier or 4-tier configurations. The telescoping slide rails make body access much easier, reducing physical strain on staff.

Body boards come in standard widths of 23", 27", and 30" to accommodate various body sizes. Stainless steel trays offer the ultimate in cleanliness and durability - they're easy to sanitize and built to last decades.

Additional customizations include interior lighting upgrades for better visibility, temperature alarms for peace of mind, exterior graphics for branding, and specialized door hardware for improved security. We work closely with each facility to create solutions that match their specific operational needs and budget constraints.

Features, Installation & Compliance for an Upright Mortuary Cooler

When you invest in an upright-mortuary-cooler, you're getting more than just a refrigerator - you're getting a precisely engineered system built to meet the demanding requirements of funeral service.

The foundation of every quality upright cooler starts with closed-cell polystyrene insulation packed into 4-inch thick panels. This isn't your typical cooler insulation - it's rated at R-32, which means superior temperature holding power even when ambient temperatures climb. These panels meet both DOE and EISA 2007 energy efficiency standards, so you're saving on energy costs too.

Safety and sanitation compliance come standard with UL and NSF ratings. The UL certification ensures electrical safety, while NSF approval means the materials meet food-grade sanitation standards. Interior vapor-proof LED lighting provides crystal-clear visibility while standing up to the humid conditions inside the cooler.

Here's what makes installation so simple: every unit runs on standard 110V power. Just plug it into a regular wall outlet and you're ready to go. No electrician needed, no special wiring, no headaches. The self-contained refrigeration system means no external drainage either.

Temperature control comes through digital thermometers with adjustable controllers that maintain those critical 36-39°F ranges. The gasketed doors use NSF-rated vinyl seals that resist staining and provide reliable temperature barriers.

For deeper details about regulatory requirements and compliance standards, check out our comprehensive guide on mortuary cooler requirements.

Upright Mortuary Cooler Maintenance Checklist

Keeping your upright-mortuary-cooler running smoothly doesn't require a maintenance degree - just consistent attention to a few key areas.

Daily tasks are straightforward: sanitize interior surfaces with approved disinfectants and check that temperature display for proper readings. Most facilities incorporate this into their end-of-day routine. Document those temperatures in your facility logs - health inspectors love to see consistent record-keeping.

Quarterly maintenance focuses on those condenser coils. Dust and debris make your compressor work overtime, driving up energy costs and shortening equipment life. A simple coil cleaning every three months keeps everything running efficiently.

Annual inspections dig deeper into gasket condition, door alignment, and overall refrigeration performance. Replace worn gaskets immediately - they're inexpensive compared to the cost of temperature fluctuations or equipment failure.

Smart facilities keep spare part kits on hand with gaskets, light bulbs, and basic hardware. When you need a replacement gasket at 2 AM, you'll be grateful you planned ahead.

Regulatory Standards & Best Practices

Navigating mortuary cooler regulations might seem complex, but the basics are straightforward. State health codes vary, but most require maintaining temperatures between 36-39°F with continuous monitoring and documentation. Some states go further, mandating backup power systems or temperature alarms for critical facilities.

CDC guidance emphasizes proper ventilation around cooling equipment and regular sanitization protocols. OSHA handling requirements focus on worker safety when moving bodies and operating equipment, which includes proper lifting techniques and personal protective equipment.

Funeral industry best practices have evolved from decades of experience. Maintaining 30-day temperature logs isn't just good practice - it's often required. Implementing preventive maintenance schedules and training staff on proper equipment operation creates consistency that inspectors appreciate.

The good news? When you choose a quality upright-mortuary-cooler that meets all these standards from day one, compliance becomes routine rather than stressful.

Cost, Warranty & After-Sales Support

When you're considering an upright-mortuary-cooler, you'll find our pricing remarkably reasonable compared to custom installations. Basic 2-body units start at $6,905, while our largest 12-body models top out at $24,799. That's a fraction of what you'd pay for a custom walk-in cooler, which often runs north of $30,000.

We understand that cash flow matters in your business. That's why we offer financing with 0% down and deferred payments for 90 days (subject to credit approval). This means you can get the cooling capacity you need today without straining your budget.

Our warranty coverage reflects the confidence we have in American-made quality. Panel and door warranties run 15 years - that's longer than most car loans! Mechanical components get 5-year protection, while parts and labor coverage extends 2 years. We stand behind our work because we build these units to last.

The energy efficiency built into every unit provides ongoing ROI through reduced operating costs. That R-32 insulation and efficient compressor design we talked about earlier? They keep working for you every month by minimizing your power bills.

Operational Expenses & Energy Use

Let's talk real numbers about what it costs to run an upright-mortuary-cooler. A typical 2-body unit needs about 2,610 BTUH cooling capacity with a 1/3 HP compressor that draws 8.3 amps during operation.

Your facility's ambient temperature makes a big difference. Most units handle ambient temperatures up to 95°F without breaking a sweat. Push beyond that limit, and you might need compressor upgrades or better ventilation to maintain warranty coverage.

The R-32 insulation in these units works harder than you might think. Higher R-values mean less heat transfer, which translates to compressors that don't have to work as hard. Your electric bill will thank you.

For electrical planning, budget around 8-10 amps for a 2-body unit during operation. That fits comfortably on a standard 15-amp circuit with proper load management - no special electrical work required.

Shipping, Installation & Training

Lead times typically run 2-6 weeks depending on how much customization you need. Standard models ship faster than custom configurations, naturally.

If you choose assembled delivery, lift-gate fees will add $75-150 to your shipping cost depending on your location and unit size. Many facilities find this worthwhile to avoid assembly time.

For unassembled units, on-site assembly takes less than one hour with basic tools. We provide detailed instructions and our technicians are just a phone call away if you hit any snags.

We don't just drop off your cooler and disappear. Staff orientation sessions ensure your team knows how to operate and maintain the unit properly. We cover temperature settings, cleaning procedures, safety protocols, and basic troubleshooting.

Remote technical support means help is always available via phone or video call. Our technicians can often diagnose issues and guide repairs without expensive service calls - saving you time and money.

Our service network spans the contiguous 48 states with regional service centers strategically located to minimize response times when you need us most.

Browse our complete Upright Series Mortuary Coolers collection to see all available models and configurations that might work for your facility.

Choosing the Right Upright-Mortuary-Cooler for Your Facility

Selecting the perfect upright-mortuary-cooler for your facility isn't just about picking the biggest unit that fits your budget. It's about understanding your specific needs and matching them with the right features and capacity.

Start with capacity forecasting by looking at your numbers over the past year. How many bodies do you typically store at once? What's your busiest season? Don't forget to factor in emergency surge capacity - you'll want extra space when unexpected situations arise.

Your floor plan audit is equally crucial. That perfect spot near the prep room might not work if the door swing blocks your main walkway. Upright-mortuary-cooler units need adequate air circulation around the condenser, typically 6-12 inches on all sides.

The electrical check is usually straightforward since these units run on standard 110V power. However, verify that your chosen circuit isn't already maxed out with other equipment.

Budget versus features becomes a balancing act. While that basic 2-body unit might seem adequate now, consider whether investing in a 3-body model provides better long-term value. The price difference is often minimal compared to buying a second unit later.

Future expansion planning has saved many of my clients significant money. If you're growing or planning renovations, it might make sense to install larger capacity now rather than cramming multiple smaller units into your space later.

For detailed selection guidance, read our article on Finding the Right Upright Cooler for Your Establishment.

Upright Mortuary Cooler Selection Workflow

The needs analysis starts with honest conversations about your current challenges. Are you running out of space during busy periods? Do staff members struggle with the current setup? Document everything - from storage patterns to workflow bottlenecks.

When requesting quotes, provide as much detail as possible about your site conditions. Mention tight doorways, stairs, or other access challenges. Include your timeline requirements too.

Customization discussions often reveal opportunities you hadn't considered. Maybe you need extra-wide doors for bariatric cases, or special finishes to match your facility's décor.

Delivery coordination prevents installation headaches. Ensure someone will be available to receive the unit and that you have adequate space for maneuvering. Assembled units require forklift access, while unassembled units can be hand-carried but need assembly time.

Commissioning isn't just plugging in the unit and walking away. We'll verify proper operation, adjust settings for your specific needs, and train your staff on daily operations.

Accessory Planning & Ergonomics

Body lifts aren't just nice-to-have accessories - they're essential for staff safety and efficiency. Battery-powered scissor lifts handle up to 1,000 pounds while reducing injury risk.

Body trays and boards need careful sizing to match both your cooler dimensions and typical case requirements. Stainless steel construction costs more upfront but provides years of reliable service with easy sanitization.

Rack systems should accommodate your handling procedures. Telescoping rails make body access easier, especially for shorter staff members. Fixed racks cost less but may create ergonomic challenges.

Temperature alarms provide peace of mind during power outages or equipment failures. Modern wireless systems send smartphone alerts, letting you respond quickly even when off-site.

PPE storage solutions keep protective equipment organized and accessible. Wall-mounted dispensers near your cooler ensure staff always have what they need while maintaining sanitary conditions.

Frequently Asked Questions about Upright Mortuary Coolers

When I talk with funeral directors about upright-mortuary-cooler options, I hear the same questions over and over. These are the three most common concerns that come up during our conversations.

What power supply is required?

Here's the beauty of modern upright-mortuary-cooler units - they're designed for simplicity. Every unit operates on standard 110V household power, which means you can literally plug it into any regular wall outlet in your facility.

Most units draw between 8-10 amps during operation. To put that in perspective, that's less power than many office copiers use. Your existing 15-amp circuits can easily handle this load without any upgrades or special electrical work.

I've had funeral directors tell me they were worried about hiring electricians and dealing with complex installations. The relief on their faces when I explain it's truly plug-and-play is always rewarding to see.

How long does unassembled installation take?

If you choose an unassembled unit with our cam-lock panel system, you're looking at less than one hour from delivery to operation. That's not an exaggeration - it's really that straightforward.

The cam-lock system uses specialized hardware that creates secure, insulated joints without complicated assembly procedures. You'll need basic tools that most facilities already have: a cam-lock wrench (which we provide), power drill, level, tape measure, and rubber mallet.

Our detailed instructions walk you through each step, and we provide telephone support during assembly if you have questions. One funeral director recently told me his teenage son helped with the assembly and they finished in 45 minutes while having a conversation.

The assembled option eliminates installation time entirely, though it requires forklift access for delivery. Many facilities prefer the unassembled approach for the cost savings and flexibility.

Are upright mortuary coolers compliant with DOE regulations?

Absolutely. Modern upright-mortuary-cooler units meet all Department of Energy efficiency standards under EISA 2007 regulations. This compliance isn't just about following rules - it directly benefits your operating costs.

Our units feature R-32 rated insulation and energy-efficient compressors that exceed federal requirements. The 4-inch thick closed-cell polystyrene panels provide superior temperature retention, which means the compressor doesn't have to work as hard to maintain proper temperatures.

This efficiency translates to real savings on your electric bill. One hospital administrator calculated that upgrading to a compliant unit reduced their cooling costs by nearly 30% compared to their old equipment.

The DOE compliance also ensures you're investing in equipment that meets current standards and won't become obsolete due to changing regulations.

Conclusion

At American Mortuary Coolers, we've seen how the right upright-mortuary-cooler can transform a facility's operations. Based in Tennessee, we take pride in manufacturing durable, custom solutions that serve funeral professionals across all 48 contiguous states.

What makes upright coolers so special? It's really the perfect balance of practicality and performance. You get professional-grade refrigeration without the headaches of complex installations or massive space requirements. Whether you're running a small rural funeral home or managing a busy hospital morgue, these units adapt to your needs rather than forcing you to adapt to them.

Our made-in-USA quality isn't just a marketing phrase - it's a commitment. When you invest in one of our units, you're getting equipment built to last, backed by 15-year panel warranties and comprehensive service support. We don't just sell you a cooler and disappear; we're here for the long haul.

The funeral industry has evolved tremendously over the years, and cooling technology has kept pace. Today's upright-mortuary-cooler units offer features that would have seemed impossible just a decade ago: plug-and-play installation, energy-efficient operation, and customizable configurations that fit virtually any space or workflow requirement.

What really sets us apart is our custom manufacturing approach. No two facilities are exactly alike, so why should their cooling solutions be? From specialized door configurations to unique interior layouts, we work with you to create equipment that matches your specific operational needs.

Ready to see what an upright-mortuary-cooler can do for your facility? Request a custom quote today and let our experienced team help you design the perfect cooling solution. We'll walk you through every option and make sure you get exactly what you need.

For more comprehensive guidance on selecting mortuary refrigeration equipment, check out our detailed resource: Cold Comfort: Choosing the Right Mortuary Refrigeration Unit. It's packed with insights that can help you make the best decision for your facility's future.