A Comprehensive Guide to Replacement Walk-In Cooler Doors

Why Walk-In Cooler Door Performance Matters for Your Facility

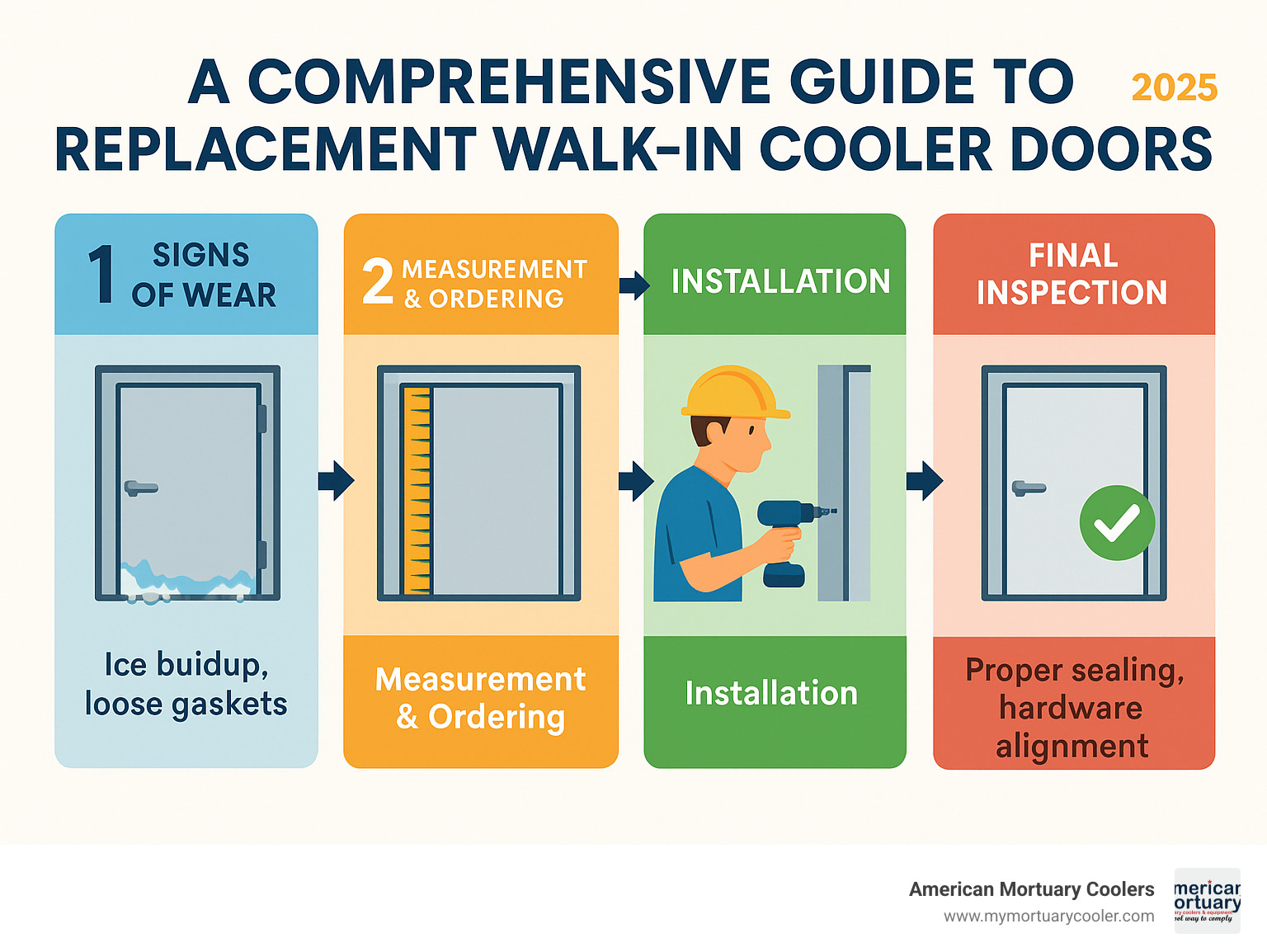

Replacement walk in cooler doors are essential when your existing doors show signs of wear, energy loss, or safety issues. Here's what you need to know:

Key Types Available:

- Swinging doors - Most common, 33" standard width, cam-lift hinges

- Sliding doors - Space-saving, manual or electric, up to 8'x10'

- Vertical-lift doors - High-ceiling applications

Standard Specifications:

- Sizes: 20+ standard options, custom up to 60"x94"

- Materials: 26-gauge stucco steel, stainless steel options

- Insulation: R-25 coolers, R-32 freezers with anti-condensation heating

- Lead time: 7-21 business days after approval

Price Range:

- Pre-hung doors: $1,450-$5,500

- Used options: Starting at $750

- Sliding systems: $3,500-$8,200

When your walk-in cooler door starts showing ice buildup, loose hinges, or air leaks, it's costing you money every day through wasted energy and potential product loss. A door that doesn't seal properly can increase your energy bills by 15-25% while putting your stored products at risk.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping facilities select and install replacement walk in cooler doors that meet their specific operational needs.

Replacement walk in cooler doors terms to remember:

Why Staying on Top of Door Performance Matters

Prevention is always more cost-effective than emergency replacement. Regular door maintenance and timely replacement contribute to sustainability goals by reducing energy waste and extending refrigeration system life. A well-maintained door system can last 15-20 years with proper care, while a neglected door might fail within 5-7 years.

When & Why You Need Replacement Walk-In Cooler Doors

Age-related wear typically appears around the 10-year mark, though harsh environments accelerate this timeline. The main culprits are damaged gaskets - those rubber seals that keep cold in and warm air out. When they crack or lose grip, you're fighting a losing battle.

Warped frames from temperature fluctuations and moisture create gaps that become highways for warm air. Icing issues signal deeper problems - excessive frost means warm, humid air is infiltrating where it shouldn't.

Code compliance requirements evolve, and older doors may not meet current standards. Energy audits often reveal how much failing doors cost in wasted energy. The ROI on door replacement typically pays for itself within 2-3 years through energy savings alone.

10 Red Flags Your Existing Door Must Go

Ice build-up around door frames or gaskets signals poor sealing. Loose hinges create gaps that break the seal. Visible air leaks - if you see light or feel air movement through a closed door, you're watching money flow out.

Cracked, torn, or permanently compressed gaskets have given up their primary job. A door that won't close automatically or keeps popping open is waving a white flag. Frost accumulation on door surfaces points to insulation failure.

Difficulty opening or closing usually indicates warped frames or failed hardware. Visible rust or corrosion compromises structural integrity. Temperature fluctuations and climbing energy bills without other explanations often trace back to failing doors.

Safety & Compliance Triggers

Inside safety release mechanisms are required by code - a failed release can trap workers inside. ADA clearance requirements are mandatory for accessibility compliance. NSF and UL labels prove your doors meet food safety and electrical safety standards.

The cost of being proactive is always less than the cost of non-compliance or emergency replacement.

Cost of Doing Nothing vs. Timely Replacement

Delaying door replacement creates a cascade of problems. Utility bills creep up as refrigeration systems work overtime. Product spoilage can cost more in six months than a quality door replacement.

Staff injuries from malfunctioning doors lead to worker compensation claims. We've documented 30% reductions in energy costs after replacing failing doors. The question isn't whether you can afford to replace your door - it's whether you can afford not to.

Types, Sizes & Materials of Replacement Doors

Swinging doors are your standard option, sliding doors save space, and vertical-lift doors work for high-ceiling applications. Most come manual, with electric upgrades available. There are over 20 standard sizes available, with custom doors up to 60"x94".

Most replacement walk in cooler doors use 26-gauge stucco-embossed steel with polyurethane foam insulation. Stainless steel and aluminum options are available at higher cost. Insulation ranges from R-25 for coolers to R-32 for freezers.

| Door Type | Best For | Size Range | Price Range |

|---|---|---|---|

| Swinging | General use, easy operation | 30"x78" to 60"x84" | $1,450-$3,500 |

| Sliding | Limited space, forklift access | Up to 8'x10' | $3,500-$8,200 |

| Vertical-Lift | High ceilings, overhead clearance | Custom sizes | $4,000-$7,000 |

Swinging Doors: The Everyday Workhorse

Swinging doors make up about 80% of installations. The 33" man-door width is the sweet spot for most applications. Cam-lift hinges lift the door slightly when opening, reducing threshold wear and extending seal life.

Kickplates protect surfaces from cart damage. Diamond plate kickplates are worth the cost for busy kitchens.

Sliding Doors for Tight Aisles

Sliding doors work great for tight spaces or forklift traffic. Horizontal glide systems handle openings up to 20 feet wide. Bi-parting options provide full opening width with less side clearance.

Electric sliding doors with motion sensors are game-changers for forklift operations, allowing operators to enter without dismounting.

Vertical-Lift & Specialty Doors

Vertical-lift doors slide straight up, keeping floor space clear for tall loads. Specialty doors include French doors, blast doors, and hermetically sealed doors for specific applications.

Custom vs. Standard Sizing Explained

Standard sizes cover most situations. Custom sizing handles unusual installations. Key measurements include rough opening and choosing between plug frame and jamb frame styles. Overlap style doors work with many walk-in brands.

Finishes & Insulation Choices

Stucco embossed galvanized steel is standard and durable. Stainless steel upgrades work for high-hygiene applications. Closed-cell urethane foam outperforms expanded polystyrene (EPS) by maintaining R-value over time and resisting water absorption.

Scientific research on high-R insulation shows proper insulation can cut energy consumption by 20-30%.

Measuring, Ordering & Lead Times for Replacement Walk-In Cooler Doors

Accurate measurements determine project success. You'll need a tape measure, level, and notepad. Wall thickness is critical - most walk-in walls are 4 inches thick, but verify yours. Door swing direction affects hardware placement and staff movement patterns.

The ordering process requires detailed specifications and drawings needing approval before manufacturing. Most replacement walk in cooler doors require 2-3 business days for design approval, followed by 7-21 days for manufacturing.

More info about walk-in cooler door hardware covers technical hardware details.

How to Measure Like a Pro for Replacement Walk-In Cooler Doors

Measure the clear opening - the actual space your door fills. Don't measure the old door; measure the opening. Threshold height is crucial for ADA compliance. Account for thermometer wiring and electrical components.

Take photos from multiple angles for reference during ordering and installation.

The Ordering Checklist

Complete drawings and approvals prevent costly mistakes. Specify all hardware options, electrical requirements, and finish details upfront. Consider delivery logistics - truck access and lift-gate service needs.

Download our cut sheet Not sure where to start? guides you through specifications.

Typical Production & Shipping Timeline

Standard doors ship in 7-10 business days after approval. Custom doors take 14-21 business days. Rush options are available for emergencies at premium pricing.

Freight shipping requires planning. Lift-gate service is usually worth the cost unless you have dock-level loading. We coordinate delivery timing with your schedule.

Installation, Upgrades & Ongoing Care

Modern doors come with retrofit frames that overlap existing panels, making installation straightforward. Bolt-on kits include everything needed. For freezers, don't forget heated threshold wiring to prevent ice buildup.

Proper alignment prevents premature gasket wear and air leaks. Gasket care and yearly hinge lubrication extend door life significantly. Standardized components make replacement parts easier to source.

Explore Parts Explore Parts for replacement components.

Step-by-Step Door Swap

- Remove old door - disconnect electrical connections, remove hinge pins

- Square the new frame using a level - this determines long-term performance

- Apply foam seal around perimeter for airtight barrier

- Test all hardware thoroughly - latches, closers, and electrical components

The process typically takes 2-4 hours. Professional installation ensures warranty compliance.

Popular Accessories & Add-Ons

Hydraulic closers ensure consistent closing. Strip curtains provide extra insulation for high-traffic areas. LED lighting is more efficient and longer-lasting. Vision windows let you see inside without opening doors. Digital thermometers with external displays help monitor temperatures.

Maintenance Hacks to Extend Life

Clean gaskets monthly with mild soap - this simple step can double door lifespan. Adjust door closers seasonally as hydraulic fluid changes with temperature. Replace door sweeps when worn - they're inexpensive but crucial for sealing.

Schedule annual inspections to catch problems early. Simple maintenance easily doubles door system life.

Cooler vs. Freezer: What Changes in Replacement Walk-In Cooler Doors

Freezer applications need serious upgrades. Freezer perimeter heat wire prevents gaskets from freezing solid. Heated vent ports solve pressure equalization issues as air contracts and expands with temperature changes.

Insulation jumps from R-25 panels for coolers to R-32 panels minimum for freezers. Anti-condensation systems prevent ice buildup that jams doors and damages seals.

Choosing the Right Heater Package for Replacement Walk-In Cooler Doors

Voltage matching is critical - your facility determines 115V or 208V requirements. Energy draw varies from 50 watts for small doors to 200+ watts for large doors in extreme conditions.

Failure signs include ice formation around gaskets, doors that stick, or visible frost on surfaces. Match heater capacity to actual conditions - oversized heaters waste energy while undersized heaters fail when needed most.

Energy & Safety Implications

Proper frost prevention reduces overall energy consumption by maintaining seal integrity. Door adhesion from ice creates safety concerns and staff injuries. Consistent door operation ensures emergency evacuation capability and maintains temperature integrity for stored products.

Frequently Asked Questions about Replacement Walk-In Cooler Doors

How much does a replacement walk-in cooler door cost?

Replacement walk in cooler doors range from $1,450 for basic pre-hung doors to $5,500 for larger specialized units. Used doors start around $750 but may lack newer safety features and warranties. Sliding door systems run $3,500-$8,200 depending on size and operation type.

Final price depends on size, materials, insulation rating, hardware, and electrical features. Custom sizes typically cost 20-30% more than standard doors.

Can I install a replacement door myself or do I need a pro?

While DIY installation is possible with skilled maintenance teams, professional installation protects warranties and ensures proper alignment, sealing, and electrical connections. Even small mistakes can lead to energy loss and future problems. Professional installation often pays off through better efficiency and fewer adjustments.

Are refurbished doors a good option?

Refurbished replacement walk in cooler doors work well for budget-conscious situations. Quality refurbished units are inspected and often mounted on new frames. However, they may lack latest energy-saving features and have shorter lifespans than new doors.

For questions about what's best for your facility, contact American Mortuary Coolers - we're here to help guide you through the selection process.

Conclusion & Next Steps

Choosing the right replacement walk in cooler doors is an investment in your facility's future. At American Mortuary Coolers, our expertise extends beyond Tennessee and mortuary specialization to help restaurants, cold storage facilities, and any business requiring reliable refrigeration.

What makes us different is our commitment to custom solutions that fit your specific needs. Quality door replacement provides lower energy bills, fewer emergency calls, and staff who can focus on their real jobs instead of wrestling with broken doors.

We build every door to last because we've seen what happens when facilities cut corners. Our nationwide delivery across the contiguous 48 states ensures consistent quality regardless of location, with timing coordinated to minimize operational disruption.

More info about dead body storage freezer door maintenance provides additional specialized maintenance insights.

Smart facility managers don't wait for complete door failure. They recognize warning signs - ice buildup around gaskets, doors that don't close properly, or gradually increasing energy bills. Taking action before crisis hits saves money and prevents emergency replacement headaches.

Ready to upgrade with replacement walk in cooler doors that actually work properly? Our team will help you steer options, get measurements right, and invest in doors that will serve your facility for years to come.

Contact us today for a personalized quote and find why facilities across the country trust American Mortuary Coolers for their critical cold storage needs.