A Comprehensive Guide to Reefer Trucks

Why REEFER-truck- Solutions Are Essential for Temperature-Controlled Transport

A REEFER-truck- is a refrigerated vehicle designed to transport temperature-sensitive goods while maintaining precise climate control throughout the journey. These specialized trucks use built-in refrigeration systems to keep cargo at specific temperatures, typically ranging from -20°F to 55°F.

Key REEFER-truck- Facts:

- Definition: Van or truck with active cooling system for perishable freight

- Temperature Range: -20°F to 55°F for various cargo types

- Main Components: Compressor, condenser, evaporator, and diesel generator

- Applications: Food transport, pharmaceuticals, medical supplies, and mortuary services

- Industry Impact: Around 4 million refrigerated vehicles operate worldwide

The refrigerated trucking industry traces back to 1925 when Frederick McKinley Jones developed the first mechanical refrigerated trucks. Today, these vehicles are critical for maintaining the cold chain - the unbroken series of refrigerated production, storage, and distribution activities.

Modern reefer trucks range from compact 14-foot box trucks to massive 53-foot semi-trailers with sophisticated Transport Refrigeration Units (TRUs). The average reefer freight rate is $3.04 per mile, reflecting the premium value of temperature-controlled transport.

Beyond traditional food and pharmaceutical delivery, reefer trucks serve specialized markets including mortuary services. During the COVID-19 pandemic, CBS News reported that refrigerated trucks were deployed as temporary morgues when traditional facilities reached capacity.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in refrigerated storage solutions including REEFER-truck- applications for funeral home operations.

Quick look at REEFER-truck-:

REEFER-truck- Basics: Definition & Core Components

What makes a REEFER-truck- different from your everyday delivery truck? It's all about active cooling power instead of just basic insulation. The story starts back in 1925 when Frederick McKinley Jones changed everything by creating the first mechanical refrigeration system for trucks.

Think of a reefer truck as a mobile freezer that can travel thousands of miles while keeping your cargo at exactly the right temperature. Whether you need frozen goods at -20°F or fresh produce at 55°F, these trucks maintain precise climate control throughout the entire journey.

Every reefer system relies on four essential components working together. The compressor acts as the heart of the operation, pressurizing and liquefying refrigerant using power from either the truck's engine or a dedicated diesel generator.

The condenser sits outside the cargo area, working as a heat exchanger that releases warmth from the refrigerant into the outside air. Inside the cargo compartment, the evaporator does the heavy lifting by absorbing heat from your cargo.

The Transport Refrigeration Unit (TRU) brings everything together as the complete system. Modern TRUs can run independently of the truck's main engine, which means your cargo stays cool even when the truck is parked for loading or unloading.

Today's reefer trucks handle an impressive temperature range from -20°F to 55°F. The secret lies in high-quality insulation made from foamed-in-place polyurethane with R-values exceeding R-25 for coolers and R-32 for freezers.

| Feature | Reefer Truck | Dry Van |

|---|---|---|

| Temperature Control | Active cooling/heating | Ambient only |

| Insulation | R-25 to R-32 foam | Minimal |

| Power Requirements | Diesel TRU or electric | None |

| Cargo Types | Temperature-sensitive | Dry goods only |

| Operating Costs | Higher (fuel, maintenance) | Lower |

| Freight Rates | Premium ($3.04/mile avg) | Standard |

At American Mortuary Coolers, we understand how critical precise temperature control is for specialized applications like mortuary services. For more detailed information, check out Everything You Need to Know About Reefer Lorries.

How a REEFER-truck- refrigeration cycle works

The magic behind a REEFER-truck- happens through a closed-loop system that continuously removes heat from your cargo area. The journey starts with the compressor pressurizing gaseous refrigerant, which heats up during compression. This hot, high-pressure gas flows to the condenser, where it releases heat to the outside air and transforms into liquid form.

Next, the liquid refrigerant passes through an expansion valve where pressure drops dramatically, causing the refrigerant to become extremely cold. This super-cold refrigerant enters the evaporator inside your cargo area, where it absorbs heat from your cargo and the surrounding air.

Most reefer units run on diesel generators that operate independently of the truck's main engine. Many facilities offer electric standby connections that let you plug in during loading and unloading, which saves fuel and reduces emissions.

Key Features & Specs of Modern Units

Modern reefer trucks can create multi-temperature zones within the same trailer, allowing you to transport frozen foods at -10°F alongside fresh produce at 34°F - all in one trip.

Semi-trailers typically range from 28 to 53 feet, while box trucks usually measure between 14 to 26 feet for local delivery. Most TRU systems carry approximately 50 gallons of fuel specifically for refrigeration.

Today's telematics systems transform how fleet managers monitor their reefer operations with real-time tracking of temperature readings, fuel levels, and equipment status. Solar-assisted TRUs represent the cutting edge, reducing fuel consumption by 15-25%.

Premium units include automatic defrost cycles, humidity control, data logging capabilities, and remote diagnostics that help predict maintenance needs before breakdowns occur.

Types, Sizes & Industry Applications

When it comes to REEFER-truck- options, there's truly something for every business need. Straight trucks are the workhorses of local delivery, coming in sizes from 14 to 26 feet and handling about 15,000 pounds of cargo.

For the heavy lifting, semi-trailers rule the road. These 53-foot giants can haul 43,000 to 45,000 pounds of cargo across the country. Box vans fill the gap for urban deliveries where bigger trucks can't steer tight city streets.

5-ton reefers hit the sweet spot for regional distribution. Take the International MV607 with a 24-foot reefer body - it offers 260 horsepower with 12,000-pound front and 21,000-pound rear axle capacities.

The applications for refrigerated transport stretch far beyond grocery delivery. Foodservice remains the biggest market, with the Food Safety Modernization Act (FSMA) requiring proper temperature control throughout the supply chain.

Pharmaceuticals present unique challenges with temperature-sensitive medications and vaccines needing precise climate control. Some biologics require storage at -80°F, which means specialized ultra-low temperature equipment.

The mortuary services industry relies heavily on refrigerated transport. During the COVID-19 pandemic, CBS News reported that Texas and Arizona requested refrigerated trucks as temporary morgues when traditional facilities reached capacity. Our experience with Cold Storage Solutions: Top Morgue Freezers Available Today extends to mobile refrigeration solutions.

Flower transport demands exact temperature and humidity control, typically maintaining 34°F to 38°F. Beyond these common applications, REEFER-truck- vehicles transport paint, cosmetics, electronics, fine art, and musical instruments.

Matching the Right REEFER-truck- to Your Business

Choosing the right REEFER-truck- requires honest assessment of your needs. A 53-foot reefer trailer typically weighs 13,000 to 15,000 pounds empty, leaving you 43,000 to 45,000 pounds for cargo. Smaller straight trucks offer 8,000 to 15,000 pounds of payload capacity.

The single versus multi-temperature decision comes down to flexibility versus complexity. Single-temperature units cost less and break down less often, but multi-temperature units let you mix frozen and fresh products in the same load.

Your route type shapes everything else. Regional delivery routes under 500 miles work well with straight trucks, while long-haul cross-country routes need those 53-foot trailers to maximize cargo capacity.

Companies like Penske offer refrigerated truck rentals with body lengths from 14 to 26 feet, including 688 refrigerated trucks that meet FSMA guidelines.

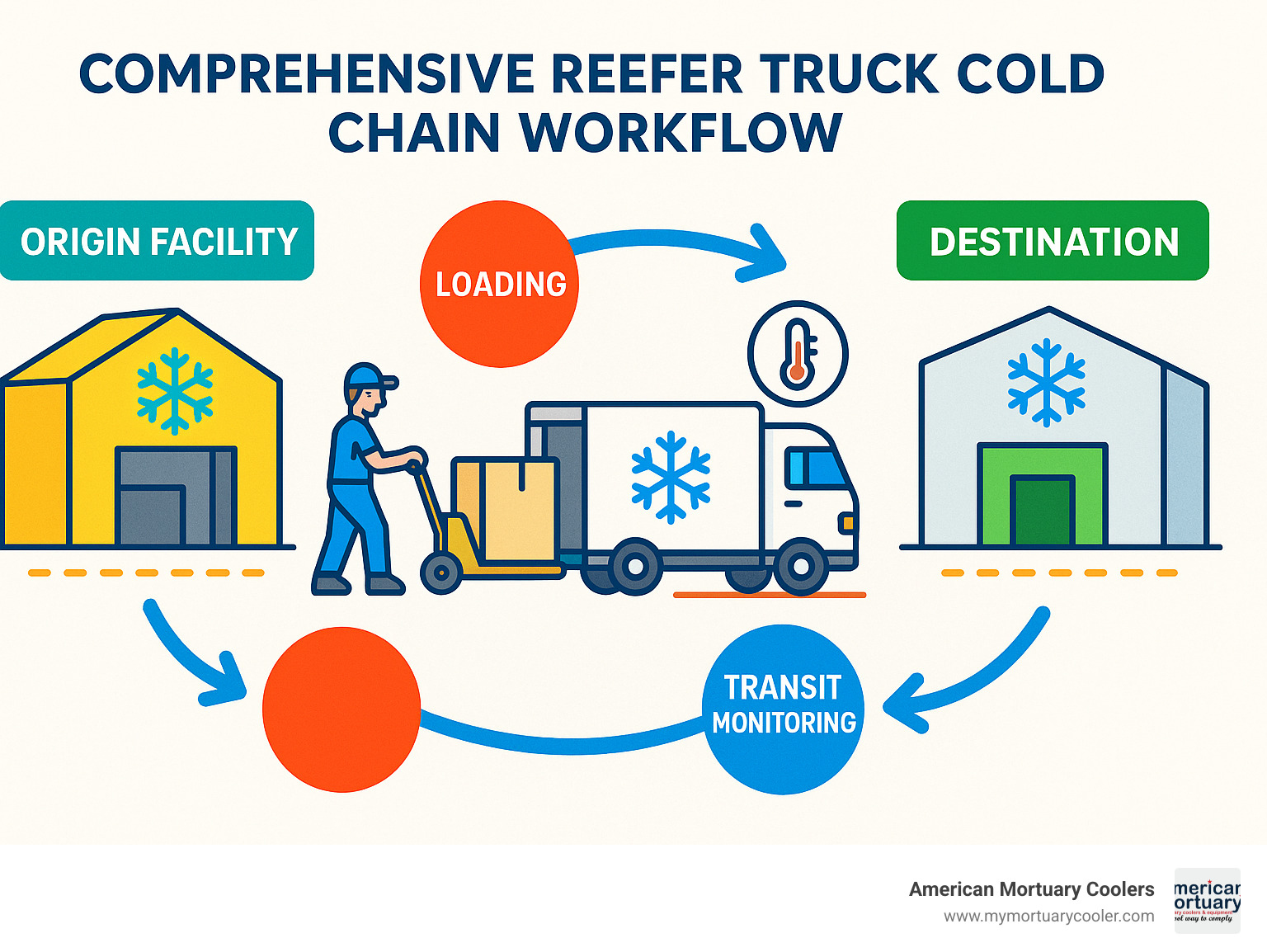

Contribution to the Cold Chain & Food Safety

The REEFER-truck- serves as a critical link in the cold chain - that unbroken series of refrigerated storage and transport from farm to your dinner table. Break this chain anywhere, and you risk spoilage, waste, and potentially dangerous foodborne illness.

FSMA guidelines require documented temperature logs and sanitary transport practices. HACCP compliance identifies temperature control as a critical control point, requiring continuous monitoring and immediate corrective action when things go wrong.

Temperature loggers in modern systems automatically record data throughout transport, serving as legal documentation that products stayed within safe temperature ranges. Sanitation requirements mean reefer trailers must be cleaned and sanitized between loads.

Proper temperature control prevents bacterial growth in fresh foods, enzymatic reactions that cause spoilage, moisture loss that affects product quality, and chemical degradation in pharmaceuticals. For detailed information, check out this Scientific research on transportation of refrigerated foods.

Ownership, Rental & Cost Considerations

When you're ready to add a REEFER-truck- to your fleet, you'll face the classic business decision: buy, lease, or rent? Each path has its own benefits depending on your cash flow, business goals, and usage frequency.

Buying new gives you the latest technology, full warranties, and zero surprises in maintenance history, but hits your wallet hard upfront. Buying used is where smart money often goes. Penske's current inventory includes 688 refrigerated trucks for sale, with significant cost savings over new units.

Leasing offers predictable monthly payments, often with maintenance packages included, and preserves capital for other business needs. Short-term rental works beautifully for seasonal businesses, with daily rates averaging around $190 and weekly rentals about $800.

The good news? Reefer loads command premium rates - averaging $3.04 per mile compared to $2.50 for dry van freight. Red-dyed diesel for your TRU operation comes tax-free, helping offset operating costs.

Purchase vs Lease Breakdown

Purchasing builds ownership equity over time and gives you complete freedom - no mileage restrictions or usage penalties. However, you're responsible for substantial upfront capital and bear all depreciation risk.

Leasing offers lower monthly payments with maintenance packages often included, making budgeting easier. Trade-offs include mileage caps with expensive overage charges, zero equity building, and restrictions on modifications.

Seasonal flexibility often tips the scales toward leasing. Many businesses ride seasonal demand cycles, and leasing lets you adjust fleet size accordingly. The sweet spot often depends on your utilization rate - high-mileage, year-round operations usually favor purchasing.

Operating Costs & Fuel Efficiency

Running a REEFER-truck- involves ongoing costs that can surprise newcomers. Your TRU system alone burns 0.5-1.0 gallons of diesel per hour. For high-utilization vehicles, annual refrigeration fuel costs can hit $4,000-$5,000.

Electric standby connections at loading docks can slash fuel consumption by 50-75% during loading and unloading. Maintenance for the refrigeration system typically runs $1,500-$2,500 annually.

Solar-assisted TRUs reduce fuel consumption by 15-25%, while electric reefer units eliminate diesel costs entirely. Smart operators maximize efficiency through pre-cooling cargo before loading, proper loading techniques that maintain airflow, and driver training on energy-saving TRU operation.

Maintenance, Regulations & Sustainability

Taking care of your REEFER-truck- isn't just about keeping it running - it's about protecting your cargo, staying legal, and controlling costs. Daily checks keep small problems from becoming big headaches. Weekly maintenance includes cleaning condenser coils and checking refrigerant levels. Monthly inspections should test defrost cycles and calibrate temperature controls.

Quarterly professional service is worth every penny, with qualified technicians checking your compressor and electrical systems. Annual overhauls ensure compliance and efficiency, including refrigerant leak testing.

The regulatory landscape focuses on safety, environment, and food protection. FDA sanitation rules require proper cleaning between loads. CDL requirements apply to vehicles over 26,000 pounds, with some states requiring a reefer endorsement.

CARB compliance matters for California operations, while the AIM Act phases down hydrofluorocarbon (HFC) refrigerants, pushing toward more environmentally friendly options.

Compliance Checklist for REEFER-truck- Operators

Your pre-trip inspection should verify the TRU is running smoothly and maintaining proper temperatures. Check fuel levels, DEF supply, and door seals. Temperature documentation provides legal protection - continuous logging proves you maintained proper conditions.

Insurance coverage for refrigerated transport includes cargo insurance for temperature-sensitive goods and breakdown coverage for TRU failures. For funeral industry applications, our experience with Everything You Need to Know About Mobile Mortuary Freezers helps ensure compliance.

The FDA provides comprehensive guidance on sanitary transportation, covering proper cleaning, temperature control, contamination protection, and documentation procedures. Check the FDA transportation sanitation guidance for complete requirements.

Green Tech & Future Trends

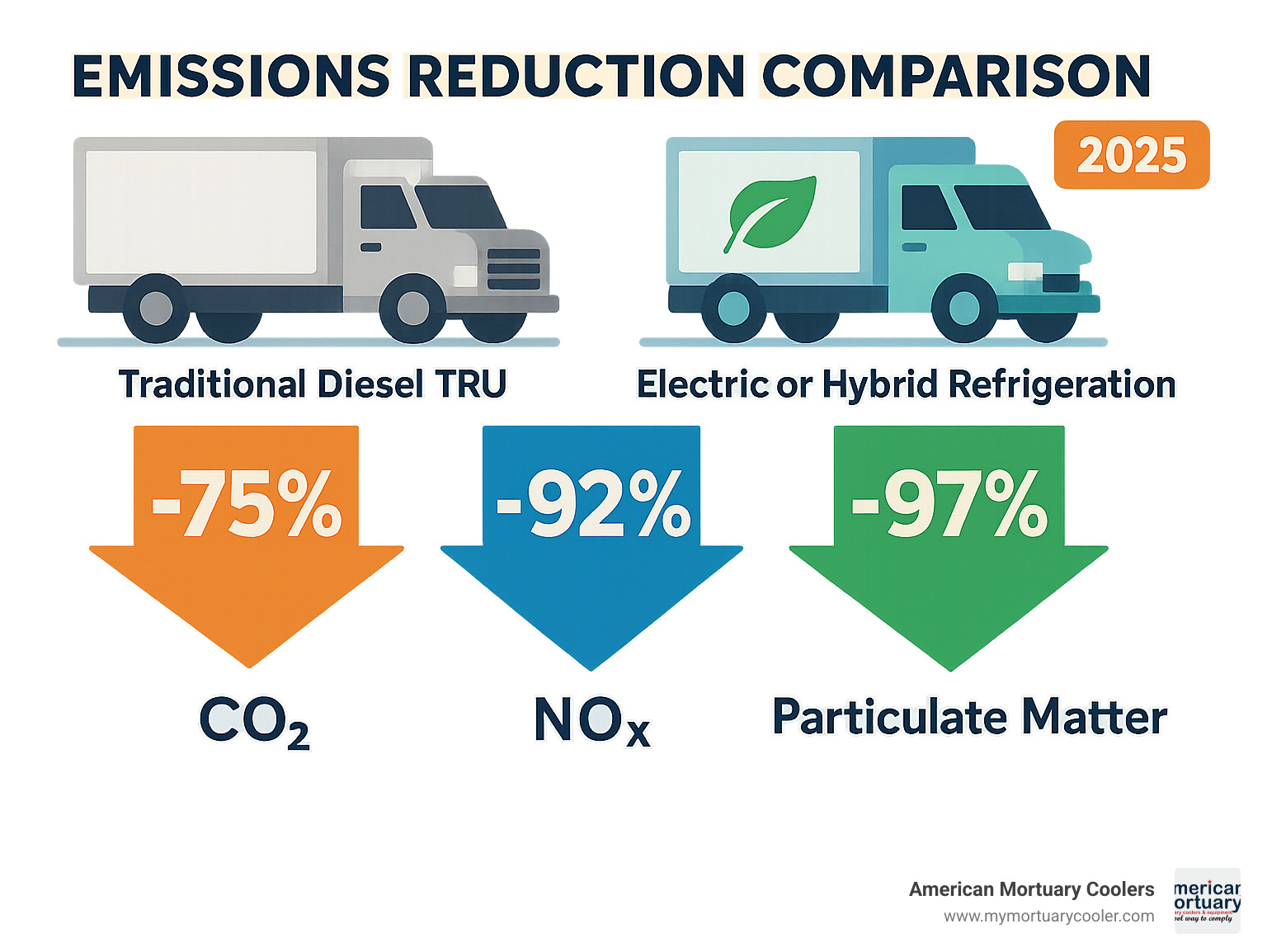

The REEFER-truck- industry is getting a green makeover. Battery-electric reefers eliminate diesel fuel completely, running on clean electricity with dramatically lower operating costs and whisper-quiet operation.

Fuel cell technology offers another clean option with longer range than batteries and faster refueling. Smart technology with IoT sensors tracks everything from temperature to fuel consumption, while artificial intelligence analyzes data to predict component failures.

Solar integration reduces fuel consumption by 15-25%, while natural refrigerants like CO₂ replace synthetic HFCs with much lower environmental impact. The regulatory environment drives change - CARB's TRU regulation requires zero-emission units in California by 2030.

Lifecycle analysis considers environmental impact from manufacturing through disposal, helping identify the most sustainable solutions for long-term operations.

Frequently Asked Questions about Reefer Trucks

When you're considering a REEFER-truck- for your business, you probably have some burning questions. Let me address the most common ones I hear from operators looking to get into temperature-controlled transport.

What temperature range can a reefer maintain?

Here's the good news - modern REEFER-truck- systems are incredibly versatile when it comes to temperature control. Most standard units can maintain temperatures anywhere from -20°F to 55°F, which covers just about everything you'd need to transport.

For everyday operations, you'll find that frozen foods typically need temperatures between -10°F and 0°F to stay solid. Fresh produce does best in the 32°F to 40°F range - cold enough to stay fresh but not so cold that it freezes. If you're hauling pharmaceuticals, many vaccines require that precise 2°F to 8°F sweet spot.

Now, if you need something really cold - like for certain medical or scientific applications - there are specialized ultra-low temperature units that can hit -80°F. Fair warning though: these units cost significantly more to buy and operate, so make sure you really need that extreme cold before investing.

How often should TRU maintenance be scheduled?

Think of TRU maintenance like brushing your teeth - consistency is everything. Skip it, and you'll pay for it later with expensive problems.

Your daily routine should include a quick visual check of the unit and making sure your fuel levels are good. Nothing fancy, just a once-over to catch obvious issues.

Weekly maintenance is where you roll up your sleeves a bit. Clean those condenser coils (they get dirty fast), check fluid levels, and make sure everything looks normal. This takes maybe 15 minutes but prevents huge headaches later.

Monthly inspections are more thorough - test all the systems, check the defrost cycles, and make sure your temperature controls are accurate. Every three months, bring in a professional for a complete service and calibration.

The annual overhaul is your big-ticket maintenance event. This is when you get everything certified and catch any wear items before they fail. Trust me, spending money on scheduled maintenance beats losing a $50,000 load of pharmaceuticals because your compressor died on a Friday night.

Can a reefer trailer double as a dry van?

Absolutely! This is one of the smartest features of owning a REEFER-truck- - you're not stuck hauling only refrigerated cargo. When you turn off the refrigeration unit, your reefer trailer can carry regular dry freight just like any other truck.

This flexibility is a real money-maker for many operators. Let's say you deliver frozen food from Chicago to Atlanta. Instead of driving back empty (what we call "deadheading"), you can pick up a load of dry goods for the return trip. More revenue, better fuel efficiency, and happier accountants.

There's one catch to keep in mind: reefer trailers weigh more than standard dry vans because of all that insulation and refrigeration equipment. This means you'll have less payload capacity for heavy dry freight. But for many loads, this isn't a problem.

The versatility really shines when you're starting out or operating in markets where refrigerated loads aren't always available. You can keep your trucks moving and generating revenue even when the perfect reefer load isn't waiting for you.

Conclusion

The REEFER-truck- has evolved dramatically since Frederick McKinley Jones first revolutionized ice cream delivery in 1925. Today, these sophisticated vehicles keep our food fresh, medicines effective, and serve countless specialized needs across America's highways.

Whether you're hauling fresh produce or providing dignified transport services for funeral homes, the cold chain depends on reliable refrigerated transport. With reefer freight commanding premium rates of $3.04 per mile, there's real value in temperature-controlled logistics.

The choice between buying, leasing, or renting your REEFER-truck- depends on matching your equipment to your actual business needs. A small funeral home might benefit from occasional rentals, while a large food distributor needs a dedicated fleet.

At American Mortuary Coolers, we've seen how critical proper refrigeration is in sensitive situations. Our Tennessee-based team has helped funeral professionals nationwide understand their refrigeration needs, knowing there's no room for equipment failure in mortuary transport.

The industry is changing fast with electric TRUs replacing diesel units, solar panels appearing on trailer roofs, and smart sensors sending real-time alerts. California's push for zero-emission refrigeration by 2030 is just the beginning.

But all this technology means nothing without understanding the basics. Proper maintenance prevents costly breakdowns, good loading practices ensure even temperatures, and regular cleaning keeps cargo safe and customers happy.

The future looks bright for refrigerated transport. As our food system becomes more global and complex, the need for reliable cold chain transport only grows. From farm-fresh produce to life-saving vaccines, REEFER-truck- operators play a vital role in keeping America healthy and fed.

For funeral industry professionals, our comprehensive Freeze Your: Ultimate Guide to Morgue Freezers and Fridges covers both stationary and mobile solutions. We've helped countless funeral homes make informed decisions about their refrigeration needs.

Success in this business isn't just about having the right truck - it's about understanding your role in protecting public health. When you deliver fresh food or transport medical supplies, you're not just moving cargo, you're serving your community.

The REEFER-truck- industry will keep growing as long as people need fresh food and safe medicines. By understanding the technology, following regulations, and maintaining equipment properly, you can build a successful operation that serves your community while building a profitable business.

Remember - in refrigerated transport, reliability isn't just good business practice. It's everything.