A Comprehensive Guide to Choosing a Truck with Refrigeration

Why Trucks with Refrigeration Matter for Temperature-Critical Transport

A truck with refrigeration is a specialized vehicle equipped with cooling systems to transport temperature-sensitive goods while maintaining precise climate control throughout the journey. These vehicles, also called reefer trucks, use mechanical refrigeration units powered by diesel engines or electric systems to keep cargo within safe temperature ranges.

Quick Overview of Truck with Refrigeration Options:

- Self-Powered Units: Independent diesel-powered refrigeration systems (heaviest, most expensive)

- Vehicle-Powered Units: Run off truck engine or shore power (lighter, less expensive)

- Body Types: Insulated vans (14-26 ft), straight trucks, semi-trailers (up to 53 ft)

- Temperature Range: Typically -20°F to +70°F depending on unit specifications

- Common Applications: Food delivery, pharmaceuticals, floral transport, emergency morgue services

The first successful mechanically refrigerated trucks appeared in 1925 for the ice cream industry, invented by Frederick McKinley Jones. Today, approximately 4 million refrigerated road vehicles operate worldwide, forming the backbone of cold-chain logistics that keeps perishable goods safe from farm to consumer.

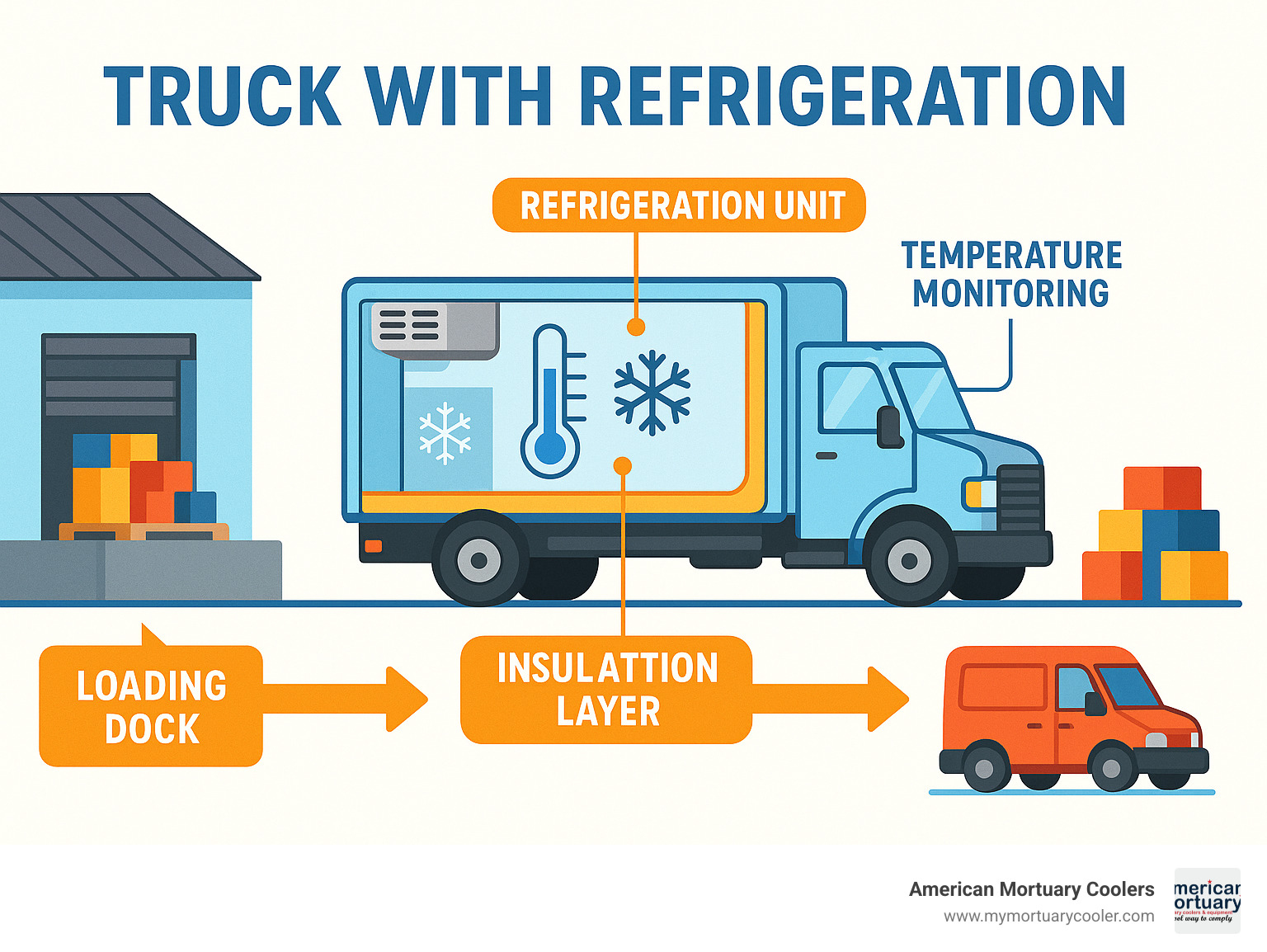

Modern refrigerated trucks maintain temperature through a closed-loop system using four key components: a compressor that pressurizes refrigerant, a condenser that releases heat, an evaporator that absorbs heat from the cargo area, and high-quality insulation that minimizes temperature loss.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping businesses select the right refrigerated transport solutions, including specialized applications for truck with refrigeration systems in emergency and healthcare settings.

Truck with refrigeration further reading:

What Is a Truck with Refrigeration and How Does It Work?

A truck with refrigeration works on the same principle as your home refrigerator, just scaled up and built tough enough to handle thousands of miles on the highway. Understanding how these systems work will help you make smarter decisions when choosing the right refrigerated transport for your business.

The magic happens through a closed-loop cooling cycle. Refrigerant flows continuously through four main parts, each doing its job to keep your cargo cold. This system traces back to Frederick McKinley Jones, whose groundbreaking work in the 1920s gave us the foundation for every modern transport refrigeration unit rolling down the road today.

For technical details behind transport refrigeration, check out this Scientific research on transport refrigeration. You can also dive deeper into the basics with our guide on More info about refrigeration basics.

Anatomy of the System

The compressor is the heart that keeps everything pumping. This powerhouse squeezes refrigerant gas and pushes it through the entire system, creating the pressure that makes the whole cycle work. Modern compressors are built to run continuously for hours without breaking down.

Once the compressor does its job, high-pressure refrigerant flows to the condenser. You'll usually find this mounted on the outside of the truck, looking like a car radiator with its coils and fins. Here's where the hot refrigerant releases heat it picked up from your cargo, changing from a hot gas into a cooler liquid.

Next comes the evaporator inside your cargo area. When that high-pressure liquid hits the expansion valve and enters the evaporator, pressure drops fast and the refrigerant evaporates. This evaporation process sucks heat right out of your cargo space, and built-in fans help spread that cold air around evenly.

Don't underestimate insulation - it's the unsung hero of the whole operation. High-quality polyurethane foam with a low K-factor wraps around your cargo area like a thermal blanket. The lower that K-factor number, the better your insulation fights heat transfer.

How a truck with refrigeration maintains temperature

Temperature control in a truck with refrigeration is all about precision and documentation. Thermostats act like vigilant guards, constantly checking the cargo area temperature and telling the refrigeration unit when to kick on or shut off. The best modern units can hold temperatures within just 1°F of your target.

Data loggers are your best friend when it comes to proving you did everything right. These devices create permanent records showing exactly what temperature your cargo experienced throughout the entire trip. If you're hauling pharmaceuticals or dealing with FSMA food safety regulations, these logs aren't just helpful - they're absolutely essential.

Main Types of Trucks with Refrigeration, Containers, and Cooling Units

When it comes to finding the right truck with refrigeration, you've got more options than you might think. Let me walk you through the main types so you can make the best choice for your needs.

Insulated vans are the compact workhorses of refrigerated transport. These smaller units typically range from 14 to 26 feet in body length, making them perfect for local deliveries and urban routes where parking space is tight. We see these used frequently in catering operations, home delivery services, and specialized mortuary applications where maneuverability matters.

Straight reefers give you that sweet spot between cargo space and city-friendly handling. These box trucks can accommodate bodies up to 26 feet long while still fitting under most bridges and into loading docks. They're incredibly popular for grocery distribution and pharmaceutical transport.

Semi-trailers are the heavy hitters for maximum hauling capacity. The standard 53-foot refrigerated trailer can handle massive loads and often features multiple temperature zones. These units are built for long-haul transport and include conveniences like electric standby power.

Special-purpose bodies solve unique problems. In our work at American Mortuary Coolers, we've seen refrigerated trucks transformed into mobile medical units, blood banks, and emergency morgue services.

Self-Powered vs. Vehicle-Powered Units

The power source for your refrigeration system is one of the most important decisions you'll make. Diesel TRUs (Transport Refrigeration Units) operate independently with their own engines, giving you maximum flexibility. Your refrigeration keeps running even when the truck engine is off.

Direct-drive electric systems connect directly to your truck's engine through a compressor. These systems have gotten incredibly sophisticated - units like the Neos 100S use the vehicle's alternator to provide consistent cooling regardless of engine speed.

Solar-assist technology is becoming more common, especially with environmental regulations tightening. All-electric solutions like the Neos 200e deliver nearly 40% more cooling capacity than older models while producing zero direct emissions.

| Feature | Self-Powered Units | Vehicle-Powered Units |

|---|---|---|

| Independence | Runs without truck engine | Needs truck running or shore power |

| Weight | Heaviest option | 75-150 lbs lighter per foot |

| Upfront Cost | Most expensive | More budget-friendly |

| Fuel Usage | Separate fuel consumption | Uses truck's fuel system |

| Maintenance | Two engines to maintain | Integrated maintenance schedule |

Selecting a truck with refrigeration for your business

Choosing the right truck with refrigeration comes down to understanding your specific needs. Body length is your starting point - think about your typical load sizes and delivery frequency. Payload calculations get tricky with refrigerated trucks because the cooling equipment eats into your carrying capacity. Always check your typical cargo weight against the truck's Gross Vehicle Weight rating.

The K-factor might sound technical, but it's simply a measure of how well your insulation works. Lower K-factors mean better temperature retention and lower fuel costs. Fuel type selection affects both your wallet and regulatory compliance.

Key Features & Buying Considerations

Shopping for a truck with refrigeration can feel overwhelming with so many options and features to consider. The key is focusing on what matters most for your specific needs.

Temperature range sits at the heart of any refrigerated truck decision. Most standard units handle anywhere from -20°F to +70°F, which covers the vast majority of applications. But if you're transporting specialized products - like certain pharmaceuticals that need ultra-low temperatures or our mortuary applications that require precise control - you'll need to verify the unit can meet those exact requirements.

The payload and GVW relationship often catches buyers off guard. That refrigeration unit adds significant weight, which directly reduces how much cargo you can legally carry. Vehicles over 10,000 lbs GVW trigger additional DOT requirements that affect your operations.

Door design might seem like a small detail, but it dramatically impacts your daily workflow. Rear barn doors work great for dock loading, while side doors help with curbside deliveries. Think about your typical delivery scenarios.

Electric standby capability has become almost essential in today's regulatory environment. This feature lets you maintain temperature without running the main engine during extended loading, overnight parking, or in areas with anti-idling regulations.

Modern telematics systems transform how you manage refrigerated transport. These systems provide real-time monitoring of temperature, location, and equipment performance while alerting you to problems before they become disasters.

For detailed information about leasing options that might fit your budget, check out our More info about reefer trailer leases.

Sustainability & Fuel Efficiency

Environmental responsibility isn't just good business anymore - it's becoming legally required in many areas. All-electric units like the E-200 help businesses meet zero-emission zone requirements that are spreading from California cities to urban areas nationwide.

Direct-drive systems typically consume less fuel than traditional self-powered units because they eliminate that separate diesel engine just for refrigeration. CARB regulations require TRU upgrades or replacements by 2025, and these California rules often become national standards eventually.

Budgeting: Buy, Rent, or Lease

Cost of ownership extends far beyond that initial sticker price. Smart buyers factor in fuel costs, maintenance expenses, insurance, and depreciation when comparing options.

Used inventory offers significant savings for budget-conscious buyers. The current market includes hundreds of quality used refrigerated trucks across various makes and body lengths.

Rental options provide flexibility for seasonal operations or temporary capacity increases. Leasing delivers predictable monthly payments and often includes maintenance packages.

Cold-Chain Applications & Real-World Examples

When people think about trucks with refrigeration, they usually picture food delivery. But these versatile vehicles serve far more purposes than most realize. In our years at American Mortuary Coolers, we've witnessed these specialized trucks become lifelines across industries where temperature control means everything.

Food and beverage transport remains the biggest market. Fresh produce needs precise humidity control to stay crisp during long hauls. Frozen foods require rock-solid sub-zero temperatures. Ice cream presents one of the toughest challenges - maintaining consistent temperatures while drivers open doors dozens of times per route.

The pharmaceutical industry demands perfection from refrigerated transport. Vaccines, insulin, and life-saving medications need temperatures between 35-46°F with zero room for error. These shipments require continuous monitoring and detailed documentation proving the cold chain never broke.

Floral transport might surprise you with its complexity. Cut flowers and plants need cool, humid conditions to maintain their beauty during transport. Too cold and they freeze. Too warm and they wilt.

Then there are the emergency applications that most people never consider. During public health crises, refrigerated trucks become temporary morgues when traditional facilities overflow. We've written extensively about this challenging topic in our analysis: Refrigerated trucks as morgues: A chilling look at emergency solutions. Scientific research on emergency refrigeration has documented how crucial these vehicles became during recent health emergencies.

Case Study Spotlight

Organic milk delivery taught us about starting smart. A new organic milk service made their refrigeration system their very first business decision. They chose a direct-drive electric unit for reliability and environmental benefits. The consistent temperature control improved product quality dramatically while cutting spoilage costs.

Vaccine distribution in rural areas presented unique challenges for a regional healthcare network. They deployed small refrigerated vans with precise temperature control, backup power systems, and comprehensive data logging to meet CDC requirements. The program successfully maintained vaccine effectiveness while bringing healthcare to underserved communities.

Ice cream quality improved dramatically for a Chennai-based distributor after upgrading their refrigerated fleet. Their old trucks couldn't handle the constant door openings during delivery routes. The new units maintained stable temperatures even with frequent access, resulting in better product texture and longer shelf life. Customer complaints dropped by 60% after the upgrade.

These real-world examples show how the right truck with refrigeration becomes more than just transportation. It becomes the foundation of business success, public health, and customer satisfaction across industries that depend on the cold chain.

Compliance, Maintenance, and Future Innovations

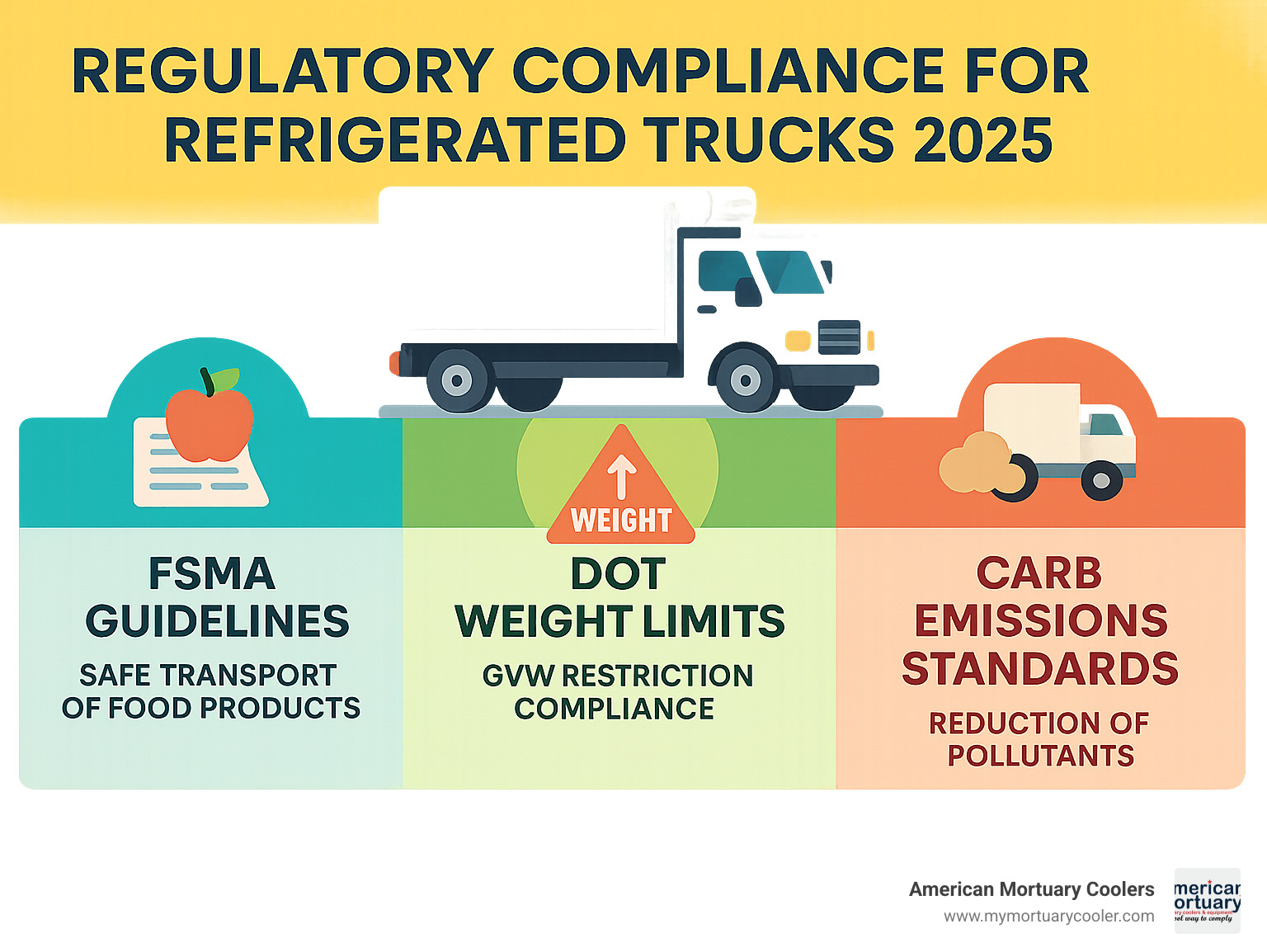

Operating a truck with refrigeration means navigating a complex web of regulations. The Food Safety Modernization Act (FSMA) sets the foundation for safe food transport, requiring detailed temperature documentation and sanitary transport practices.

DOT weight limits create what many operators call the "weight puzzle." Your refrigeration unit adds significant weight to the vehicle, which means less payload capacity for cargo. Exceeding gross vehicle weight limits can result in hefty fines and safety violations.

The CARB 2025 rules are reshaping the industry, especially for California operations. These emissions regulations mandate cleaner refrigeration systems and are driving rapid adoption of electric and low-emission units.

Modern preventive service programs like Thermo King's Performance Advantage™ take the guesswork out of maintenance scheduling. These programs include structured maintenance schedules using genuine OEM parts and often come with performance guarantees.

IoT sensors and telematics systems are revolutionizing how we monitor refrigerated transport. These smart systems provide real-time alerts about temperature fluctuations, system performance issues, and predictive maintenance needs.

For deeper insights into refrigeration system components and maintenance, check out our comprehensive guide: More info about walk-in compressors.

Routine Service Checklist

Smart operators develop consistent pre-trip inspection routines. Start by checking your refrigeration unit's operation, verifying temperature setpoints match your cargo requirements, and confirming you have adequate fuel or battery charge for the entire journey.

Refrigerant leak tests might seem like technical overkill, but they're your first line of defense against system failures and environmental violations. Don't overlook insulation audits - damaged insulation can dramatically increase energy consumption and reduce temperature control effectiveness.

Emerging Tech & Regulations for the Truck with Refrigeration Market

The future of refrigerated transport is electric, and it's arriving faster than many expected. Battery-electric TRUs like the Neos 200e deliver 40% more cooling capacity than their predecessors while producing zero direct emissions.

Solar panel integration is moving from experimental to practical, particularly for long-haul applications. The shift to low-GWP (Global Warming Potential) refrigerants represents a fundamental change in how refrigeration systems operate.

At American Mortuary Coolers, we've seen how these technological advances improve reliability and efficiency in specialized applications. The same innovations benefiting food transport are enhancing temperature control in our mortuary and healthcare applications.

Frequently Asked Questions about Trucks with Refrigeration

Let's tackle the most common questions we hear about trucks with refrigeration. After years of helping businesses choose the right cooling solutions, these are the topics that come up again and again.

How cold can a truck with refrigeration get?

Most trucks with refrigeration can handle temperatures from -20°F to +70°F, though the exact range depends on your specific unit. For everyday food transport, you'll typically see frozen goods kept around -10°F and fresh products maintained at about 40°F.

When we work with healthcare facilities, they often need tighter control - vaccines and medications usually require that 35-46°F sweet spot. The really impressive units can hold temperatures within ±1°F of your target, even when drivers are opening doors for deliveries.

The actual temperature your truck can reach depends on your refrigeration unit's horsepower, insulation quality, weather conditions, and cargo loads. In our mortuary applications, we've seen units maintain precise temperatures even in extreme conditions.

What licenses are required to drive a reefer?

Operating a truck with refrigeration means you'll need the right commercial licenses. For bigger trucks over 26,000 lbs GVWR, you'll need a Class A CDL. Smaller refrigerated trucks between 10,001-26,000 lbs require a Class B CDL.

But here's what many people don't realize - you also need a "reefer endorsement" specifically for refrigerated vehicles. This covers the special skills you need: temperature control procedures, proper cargo handling, and troubleshooting common problems.

Training programs like Elite Truck School offer specialized reefer training that goes beyond basic driving. You'll learn how to operate the refrigeration system, handle temperature-sensitive cargo, and troubleshoot problems.

How often should a refrigeration unit be serviced?

Your refrigeration unit needs regular attention to keep running reliably. Most manufacturers recommend service every 500-1,000 operating hours or quarterly - whichever comes first.

Routine maintenance covers the basics: refrigerant level checks, leak detection, belt and filter replacement, and electrical system inspection. Once a year, plan for comprehensive service that includes complete system testing and component replacement as needed.

Preventive maintenance programs from companies like Thermo King offer structured service schedules using genuine OEM parts. Regular maintenance keeps your fuel efficiency up and your temperature control accurate. A few hundred dollars in regular service beats thousands in emergency repairs and spoiled cargo every time.

Conclusion & Next Steps

Finding the perfect truck with refrigeration feels overwhelming at first, but it doesn't have to be. Think of it like choosing the right tool for your job – once you understand your specific needs, the decision becomes much clearer.

Your journey starts with understanding your cargo requirements. Fresh produce needs different handling than frozen pharmaceuticals, and emergency morgue services require entirely different specifications than ice cream delivery. The beauty of today's refrigerated transport market is that there's genuinely a solution for every application.

Self-powered units give you maximum flexibility but cost more upfront. Vehicle-powered systems save money and weight but tie you to the truck's engine. Electric units meet zero-emission requirements but need charging infrastructure. Each choice involves trade-offs, and the right answer depends on your specific situation.

At American Mortuary Coolers, we've seen how the right refrigerated transport solution transforms businesses. We've helped funeral homes manage overflow situations with emergency refrigerated trucks, worked with healthcare facilities to design mobile medical units, and supported businesses across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania with custom temperature-controlled solutions.

What sets us apart isn't just our technical expertise – it's our understanding that every refrigerated transport need is unique. Whether you're a small business making local deliveries or a large operation managing complex cold-chain logistics, we take time to understand your specific challenges before recommending solutions.

Regulatory compliance continues evolving, with CARB 2025 rules and zero-emission zones changing the landscape. The good news? Modern refrigerated trucks offer more efficient, environmentally friendly options than ever before. Investing in the right system now positions your business for future regulatory changes while improving operational efficiency today.

Don't let the technical complexity discourage you. Our team specializes in translating complex refrigeration requirements into practical, cost-effective solutions. We provide custom design services, direct delivery across the contiguous 48 states, and ongoing support to ensure your investment serves you well for years to come.

Ready to explore your options? Contact American Mortuary Coolers for personalized guidance on selecting the right truck with refrigeration for your needs. Our custom cold-storage expertise goes beyond standard applications to create specialized transport solutions that meet even the most demanding temperature control requirements.

For comprehensive information about our refrigerated solutions and how we can help protect your valuable cargo, visit More info about refrigerated solutions. We're here to help you maintain cold-chain integrity while building a transport solution that grows with your business.